Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, the sandwich press stands as a testament to innovation and culinary convenience. As a staple in homes and eateries alike, it has been a silent hero in the art of making the perfect sandwich. With advancements in technology and changing consumer preferences, the future of sandwich presses is poised to offer even more versatility and functionality. Let’s delve into the realms of what we can expect from the future of these compact yet mighty kitchen tools.

The humble sandwich press, once a simple kitchen gadget, has undergone a remarkable transformation over the years. From its inception as a tool for achieving that perfect golden-brown crust on a grilled cheese, it has evolved into a versatile appliance that caters to the diverse tastes and preferences of sandwich enthusiasts worldwide. Let’s delve into the fascinating journey of the sandwich press through the ages.

Once upon a time, sandwich presses were often crafted from cast iron and came with a classic flat-top design. These early models were simple and effective, relying on the heat generated from an open flame or a stovetop to brown and crisp the bread. The process was a bit of a science, requiring the user to time the cooking just right to avoid a soggy middle or a burnt exterior.

As the 20th century progressed, sandwich presses began to embrace the rise of electric appliances. The introduction of electric heat elements allowed for more consistent temperatures and easier operation. These early electric models often featured a single heat setting, but they laid the groundwork for the precision and convenience we associate with modern sandwich presses today.

The 1950s and 1960s saw the birth of the classic clamshell design, which remains popular to this day. This design, with its hinged lid that locks down over the sandwich, ensures even cooking and a sealed-in flavor. The clamshell press also introduced the concept of adjustable heat settings, allowing users to customize their sandwich to their liking.

As technology advanced, sandwich presses became more sophisticated. The introduction of non-stick surfaces made cleaning easier and reduced the likelihood of bread sticking to the press. Some models even began to incorporate timers and temperature controls, giving users even more precision over their cooking process.

In the 21st century, the sandwich press has expanded its repertoire to include a variety of features. Some presses now come with adjustable browning levels, allowing for a perfect shade of toast. Others have removable inserts for different shapes and sizes of sandwiches, from the classic American to the more exotic gourmet varieties.

The rise of gourmet and health-conscious eating has also influenced the evolution of sandwich presses. We now see models that can handle gluten-free breads, brioche, and even hearty whole grain loaves. Some presses even have steam functions to add moisture to the cooking process, making them versatile enough to toast sandwiches, paninis, and even grilled vegetables.

The advent of dual voltage technology has been a game-changer for the global market. The 120V/240V dual voltage sandwich press OEM has opened up new possibilities for consumers across different regions. These presses can be safely used in countries that operate on different electrical standards, ensuring that anyone can enjoy a perfectly toasted sandwich, no matter where they are in the world.

Moreover, the market has seen a surge in eco-friendly and energy-efficient sandwich presses. These models are designed not only to reduce the environmental impact but also to save consumers money on their energy bills. With the increasing awareness of sustainability, these eco-conscious presses are becoming more popular than ever.

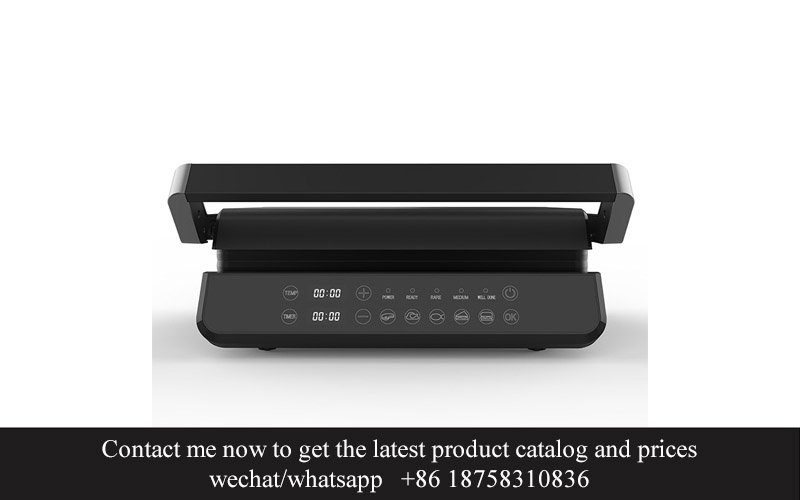

In recent years, the sandwich press has also taken a creative turn, with manufacturers experimenting with unique designs and functionalities. Some presses come with built-in grilling elements for an extra layer of flavor, while others offer digital interfaces that provide precise temperature control and cooking times.

The evolution of the sandwich press is a testament to the ingenuity of kitchen appliance designers and the ever-changing tastes of consumers. What started as a straightforward tool for making sandwiches has blossomed into a versatile and innovative appliance that can enhance the culinary experience in countless ways. As we look to the future, it’s exciting to ponder what new features and designs will emerge to keep the sandwich press relevant and beloved for generations to come.

The world of kitchen appliances has seen a myriad of innovations over the years, and one feature that has been making waves in the sandwich press industry is the 120V/240V dual voltage capability. This seemingly simple addition to a sandwich press offers a world of convenience and flexibility for both consumers and manufacturers. Let’s delve into what this dual voltage feature entails and why it’s becoming increasingly popular.

The concept of dual voltage is rooted in the fact that different countries and regions operate on different electrical standards. For instance, the United States and Canada typically use a 120V electrical system, while most of Europe and Asia operate on a 240V system. This discrepancy can pose a challenge for those who travel, move, or import appliances across borders.

The 120V/240V dual voltage sandwich press is designed to work seamlessly in both systems, eliminating the need for a bulky transformer or voltage converter. This means that a single appliance can be used globally, which is a significant advantage for both consumers and manufacturers.

One of the most apparent benefits of a dual voltage sandwich press is its portability. Imagine traveling abroad and being able to bring along your favorite sandwich press without worrying about compatibility issues. This feature is particularly appealing to frequent travelers, expatriates, and international students who want to replicate their home cooking experience wherever they go.

Moreover, for manufacturers, offering a dual voltage option can significantly expand their market reach. By producing a sandwich press that can cater to both 120V and 240V markets, companies can tap into a broader customer base without the need to create separate models for each voltage requirement.

The technical aspect of the 120V/240V dual voltage sandwich press lies in its internal components. These appliances are equipped with a voltage selector switch or a built-in transformer that allows the user to switch between the two voltage settings. This ensures that the electrical components inside the press are not damaged and that the appliance operates safely and efficiently at the correct voltage.

Safety is a paramount concern when dealing with electrical appliances, and the dual voltage feature addresses this by providing a failsafe mechanism. If the wrong voltage is applied, the appliance will either not function or will do so at a reduced power level, preventing potential damage to the device or risk to the user.

Another advantage of dual voltage sandwich presses is their ability to maintain consistent performance across different voltage levels. While some appliances may perform less efficiently or heat up unevenly when operated on an incorrect voltage, dual voltage models are designed to compensate for these fluctuations, ensuring that the sandwich-making experience remains consistent regardless of the electrical supply.

In terms of energy efficiency, dual voltage sandwich presses can also be a more environmentally friendly choice. By using the correct voltage for the local electrical system, these appliances can operate at optimal efficiency, consuming less energy and reducing electricity bills.

From a consumer perspective, the dual voltage feature offers peace of mind. No longer do you have to worry about whether your appliance will work in your new home or when you travel. This versatility is particularly attractive to those who are eco-conscious and prefer to use appliances that are energy-efficient and long-lasting.

For manufacturers, the dual voltage sandwich press represents a strategic advantage. By offering a product that is universally compatible, companies can streamline their supply chain, reduce inventory costs, and provide a more cohesive brand experience to their customers.

In conclusion, the 120V/240V dual voltage feature in sandwich presses is more than just a technical specification; it’s a testament to the evolving needs of consumers and the industry’s commitment to innovation. This feature not only enhances the usability and portability of the appliance but also aligns with the global trend towards energy efficiency and sustainability. As the demand for versatile and adaptable kitchen gadgets continues to grow, the dual voltage sandwich press is poised to become a staple in modern kitchens worldwide.

In today’s fast-paced world, the demand for versatile appliances has surged as consumers seek products that can cater to a variety of needs. This trend is particularly evident in the kitchen, where the rise of multifunctional devices has become a staple. Here’s a closer look at the factors driving the market demand for these adaptable appliances.

The ever-growing list of kitchen gadgets reflects a shift in consumer preferences. People are no longer satisfied with single-purpose tools that take up space and offer limited functionality. Instead, they’re gravitating towards appliances that can perform multiple tasks, saving time and streamlining the cooking process.

Smartphones and technology have played a significant role in shaping this demand. With the ability to multitask and perform a myriad of functions, consumers have come to expect the same level of versatility from their kitchen appliances. The integration of smart features in appliances has made them more appealing, as they can be controlled remotely and offer personalized settings.

Another driving force behind the market demand for versatile appliances is the increasing popularity of health-conscious eating habits. People are more interested in preparing meals that are not only delicious but also nutritious. Appliances that can help them achieve this, such as juicers, slow cookers, and air fryers, have seen a surge in popularity due to their ability to produce healthier alternatives to traditional cooking methods.

The trend towards smaller living spaces has also contributed to the demand for versatile appliances. Urban dwellers, especially in cities like New York, London, and Tokyo, often have limited kitchen counter space. As a result, they’re looking for appliances that can serve multiple purposes without taking up too much room. Compact, multifunctional devices like countertop ovens and all-in-one coffee makers have become favorites among these consumers.

Moreover, the rise of social media and cooking shows has inspired a new generation of home chefs. These aspiring cooks are eager to experiment with different cuisines and cooking techniques, which requires a diverse range of appliances. The availability of versatile devices that can handle various tasks has made it easier for them to explore their culinary passions.

The environmental consciousness of today’s consumers has also influenced the demand for versatile appliances. People are increasingly aware of the environmental impact of their consumption habits and are looking for sustainable solutions. Appliances that are energy-efficient and can be used for multiple purposes are seen as more eco-friendly, which is a significant factor in their purchase decisions.

Additionally, the economic climate has played a role in the demand for versatile appliances. In times of economic uncertainty, consumers are more likely to invest in products that offer long-term value and can be used for a variety of tasks. This has led to a preference for appliances that can replace multiple devices, reducing the overall cost of ownership.

Lastly, the globalization of food cultures has expanded the palate of consumers, leading to a demand for appliances that can replicate traditional cooking methods from around the world. Multifunctional appliances that can sear, bake, steam, and grill have become popular for their ability to create authentic dishes without the need for specialized equipment.

In conclusion, the market demand for versatile appliances is driven by a combination of technological advancements, health consciousness, space constraints, the rise of home chefs, environmental concerns, economic factors, and the globalization of culinary trends. As these factors continue to evolve, the demand for adaptable kitchen appliances is expected to grow, with manufacturers responding by innovating and offering a wider range of multifunctional devices.

In the ever-evolving landscape of the sandwich press industry, Original Equipment Manufacturers (OEMs) play a pivotal role in shaping the market and driving innovation. Their contributions are multifaceted, from design and engineering to market adaptation and customer satisfaction.

OEMs are the architects of sandwich press innovation. They bring fresh ideas and cutting-edge technology to the table, ensuring that the products they manufacture are not just functional but also cutting-edge. By investing in research and development, OEMs push the boundaries of what’s possible in sandwich press design, incorporating features like adjustable heat settings, non-stick surfaces, and even smart technology that allows for precise temperature control.

Customization is another key aspect of OEMs’ role. They understand that one size does not fit all, especially in a market as diverse as the sandwich press industry. OEMs work closely with brands to tailor products to specific market needs, whether it’s a compact model for a small kitchen or a commercial-grade press for busy cafes and restaurants. This level of customization ensures that the final product resonates with the target audience.

Quality control is non-negotiable in the sandwich press industry, and OEMs are at the forefront of maintaining high standards. They implement rigorous quality assurance processes to ensure that every sandwich press that leaves their facility meets the brand’s expectations and the consumer’s demands. This includes everything from material sourcing to assembly and testing, guaranteeing that the end product is durable, reliable, and safe.

Adapting to global markets is a challenge that OEMs tackle with expertise. They are well-versed in navigating different voltage standards, certifications, and cultural preferences around the world. This adaptability is crucial for brands looking to expand internationally, as OEMs can help them navigate the complexities of entering new markets with products that are both compliant and appealing to local consumers.

Sustainability is a growing concern, and OEMs are responding by integrating eco-friendly practices into their manufacturing processes. From using recycled materials to designing products that are easier to recycle at the end of their life cycle, OEMs are helping brands to offer more sustainable sandwich press options. This not only aligns with consumer values but also opens up new market opportunities for brands looking to differentiate themselves on environmental responsibility.

Innovation in manufacturing techniques is also a hallmark of OEMs in the sandwich press industry. They employ advanced production methods to streamline operations, reduce waste, and increase efficiency. This not only helps to lower costs but also allows for faster production times, ensuring that brands can meet the demands of a market that is always looking for the latest and greatest.

OEMs also serve as a bridge between brands and the end consumer. They gather valuable feedback from market research and consumer testing, which they use to refine and improve their products. This feedback loop is essential for keeping products relevant and competitive in a market that is constantly evolving.

Moreover, OEMs often take on the responsibility of marketing and branding, working closely with their clients to develop packaging, branding strategies, and promotional materials. This ensures that the sandwich press products not only perform well but also stand out on the shelves and in the minds of consumers.

Lastly, OEMs are instrumental in driving industry standards. By setting high-quality benchmarks and adhering to them, they help to elevate the entire sandwich press industry. This not only benefits the brands they work with but also contributes to the overall reputation and credibility of the industry as a whole.

In summary, OEMs are the backbone of the sandwich press industry, providing the expertise, innovation, and quality that brands and consumers rely on. Their role is multifaceted, encompassing everything from design and manufacturing to market adaptation and sustainability, making them indispensable partners in the quest to perfect the art of sandwich making.

The 120V/240V dual voltage sandwich press has emerged as a beacon of innovation in the kitchen appliance sector. This technological marvel offers a unique blend of convenience, adaptability, and efficiency, setting it apart from its single-voltage counterparts. Let’s delve into the innovations that make this sandwich press a standout in the market.

The heart of the 120V/240V sandwich press lies in its dual voltage capability. This feature allows the appliance to function seamlessly across different electrical standards, catering to a global audience. The ability to switch between two voltage settings ensures that users in regions with varying electrical systems can enjoy the same level of performance without any compromise.

One of the most notable innovations is the advanced heating element. Unlike traditional sandwich makers that often struggle with uneven heating, the dual voltage sandwich press boasts a sophisticated heating system that distributes heat evenly across the entire surface. This even heat distribution ensures that your sandwiches are perfectly toasted, with a golden-brown crust and a meltingly tender interior.

The design of the 120V/240V sandwich press is another testament to its innovative spirit. The sleek and modern aesthetic appeals to consumers looking for a kitchen appliance that not only performs well but also complements their kitchen decor. The compact size is a nod to the practicality of modern living spaces, where every inch of counter space is valuable.

In terms of functionality, the sandwich press incorporates several user-friendly features. The non-stick surfaces make for easy cleanup, and the removable plates are a breeze to wash. The adjustable heat settings allow users to customize the level of crispiness they desire, from a light toast to a deep golden brown. Additionally, the press’s locking mechanism ensures that the sandwich stays in place during the cooking process, resulting in a perfectly shaped and evenly cooked sandwich.

Safety is a paramount concern in kitchen appliances, and the 120V/240V sandwich press doesn’t skimp on this aspect. The appliance is equipped with multiple safety features, including an automatic shut-off function that activates when the press is left unattended for an extended period. This not only prevents potential accidents but also conserves energy.

Another innovation is the inclusion of a drip tray. This feature collects any excess oil or juices that may leak during the cooking process, keeping your kitchen surfaces clean and your countertops free from stains. The removable tray is easy to clean, further enhancing the appliance’s convenience.

The materials used in the construction of the 120V/240V sandwich press are of the highest quality. The stainless steel body not only adds to the appliance’s durability but also gives it a premium feel. The heat-resistant handles and the reinforced hinges ensure that the sandwich press can withstand the rigors of daily use without losing its structural integrity.

Innovation also extends to the packaging and branding of the 120V/240V sandwich press. The packaging is designed to protect the appliance during shipping and to showcase its unique features and benefits. The branding is catchy and memorable, making the sandwich press an eye-catching addition to any kitchen.

Finally, the 120V/240V sandwich press’s versatility is a significant innovation. It’s not just a tool for making sandwiches; it can also be used to cook a variety of other foods, such as grilled cheese, paninis, and even small portions of pizza. This versatility makes it a valuable addition to any kitchen, whether it’s for a busy professional or a foodie enthusiast.

In summary, the 120V/240V sandwich press is a prime example of how innovation can transform a simple kitchen appliance into a must-have tool for anyone who loves to cook. Its dual voltage capability, advanced heating system, user-friendly design, safety features, and versatility all contribute to its status as an innovative marvel in the sandwich press industry.

The 120V/240V dual voltage sandwich press has emerged as a game-changer in the kitchen appliance market, offering a versatile solution that caters to a global audience. Here’s a closer look at the benefits it brings to both consumers and businesses alike.

Efficiency Across Different RegionsOne of the standout advantages of the dual voltage sandwich press is its ability to function seamlessly in various regions around the world. Whether you’re in a country where the standard voltage is 120V or 240V, this appliance ensures consistent performance without the need for transformers or voltage regulators. This means that users can enjoy their favorite grilled sandwiches without worrying about compatibility issues, making it an ideal choice for international travelers or those living in multiple countries.

Enhanced Cooking ConsistencyThe dual voltage feature not only ensures compatibility but also contributes to enhanced cooking consistency. With the ability to adjust to different voltage levels, the sandwich press can maintain optimal heat distribution, resulting in perfectly toasted bread and a deliciously golden-brown crust. This consistency is crucial for businesses looking to provide a high-quality product every time, as well as for home cooks who want to achieve the same level of perfection in their homemade sandwiches.

Wide Range of ApplicationsThe versatility of the 120V/240V dual voltage sandwich press extends beyond just making sandwiches. Its even heat distribution and durable construction make it suitable for grilling a variety of foods, including burgers, paninis, and even vegetables. This versatility opens up new opportunities for cafes, delis, and restaurants to diversify their menu offerings without the need for additional specialized appliances.

Cost-Effective and Eco-FriendlyFrom a business perspective, the dual voltage design can be a cost-effective and eco-friendly choice. By eliminating the need for additional transformers or voltage regulators, businesses can save on energy costs and reduce electronic waste. Moreover, the press’s ability to operate efficiently at different voltage levels can help lower overall energy consumption, contributing to a greener operation.

User-Friendly DesignThe user-friendly design of the dual voltage sandwich press is another significant benefit. Its intuitive controls and easy-to-clean surfaces make it accessible to a wide range of users, from beginners to seasoned chefs. The compact size and sleek design also make it a space-saving addition to any kitchen, whether it’s a professional kitchen or a home kitchen.

Longevity and DurabilityInvesting in a dual voltage sandwich press means investing in a long-lasting appliance. The high-quality materials used in its construction ensure that it can withstand frequent use and maintain its performance over time. The durable build also means that the press can be a reliable tool for years to come, reducing the need for frequent replacements and further contributing to cost savings.

Customization and Branding OpportunitiesFor OEMs and manufacturers, the dual voltage sandwich press presents a unique opportunity for customization and branding. Businesses can have their logo or brand name engraved on the appliance, creating a personalized product that stands out on the market. This level of customization not only adds value to the product but also helps to establish a strong brand presence.

Safety and ComplianceSafety is a top priority in the kitchen appliance industry, and the 120V/240V dual voltage sandwich press is designed with this in mind. It meets international safety standards and certifications, ensuring that users can enjoy their sandwiches with peace of mind. This compliance also opens up export opportunities for manufacturers, as they can confidently market their products to a global audience.

In conclusion, the benefits of the 120V/240V dual voltage sandwich press are multifaceted, offering a combination of efficiency, versatility, cost-effectiveness, and user-friendliness. From the convenience it brings to consumers to the business opportunities it presents to OEMs, this innovative appliance is poised to make a significant impact in the sandwich press industry.

The sandwich press market has been experiencing a surge in demand, driven by several key trends and data insights that highlight its growing popularity and the evolving consumer preferences within the industry.

Consumer Lifestyle ShiftsAs life becomes more fast-paced, consumers are seeking convenience in every aspect of their daily routines. The ease of making a delicious, freshly toasted sandwich at home without the need for complex cooking skills or expensive appliances has made sandwich presses increasingly appealing.

Globalization and Diverse Culinary PreferencesWith the rise of global cuisine, consumers are looking for appliances that can replicate the flavors and textures of their favorite international dishes. This has led to a demand for sandwich presses that offer adjustable settings and non-stick surfaces suitable for a variety of ingredients and cooking methods.

Technology IntegrationThe integration of technology into kitchen appliances has been a significant trend. Smart features such as digital temperature controls, timers, and programmable settings have become standard in modern sandwich presses, allowing users to achieve consistent results every time.

Health and Wellness TrendsAs people become more health-conscious, they are opting for home cooking over processed or fast-food options. Sandwich presses enable individuals to control the ingredients used in their sandwiches, making them a popular choice for those looking to maintain a balanced diet.

Market Data HighlightsAccording to a recent report by MarketResearch.com, the global sandwich press market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2020 to 2025. This growth is attributed to the increasing number of households interested in cooking at home and the growing demand for high-quality, versatile appliances.

Sales DistributionWhen examining sales distribution, it’s evident that the sandwich press market is becoming more diverse. Online sales have been on the rise, accounting for a significant portion of total sales. Additionally, sales through brick-and-mortar stores remain strong, particularly in regions where there is a preference for in-person shopping experiences.

Price SensitivityPrice sensitivity continues to be a factor in the sandwich press market. While premium models with advanced features command a higher price point, there is also a strong market for more affordable, yet functional, sandwich presses that cater to budget-conscious consumers.

Brand Loyalty and Market SaturationBrand loyalty is a critical aspect of the sandwich press market. Established brands with a reputation for quality and innovation tend to retain customer loyalty. However, the market is becoming increasingly saturated with new entrants, which can create challenges for both established and new brands in terms of differentiation and market positioning.

Sustainability and Environmental ConcernsEnvironmental concerns are also influencing the sandwich press market. Consumers are increasingly interested in products that are made from sustainable materials and have a lower carbon footprint. This trend is pushing manufacturers to explore eco-friendly alternatives in their design and production processes.

Regulatory ComplianceRegulatory compliance remains a crucial consideration for manufacturers in the sandwich press industry. Meeting safety standards and adhering to international regulations is essential to maintain marketability and consumer trust.

The sandwich press market is dynamic, with trends and data insights pointing to a future where convenience, technology, health, and sustainability play central roles. As the industry continues to evolve, it will be interesting to see how these factors shape the future of sandwich press design and consumer preferences.

In the competitive world of kitchen appliances, finding a product that not only meets consumer needs but also differentiates your brand is crucial. Our 120V/240V dual voltage sandwich press is designed to do just that, offering a range of benefits that can significantly enhance your business.

The convenience of dual voltage is a game-changer. By catering to markets that operate on different electrical standards, you open up your customer base to a broader demographic. This versatility ensures that your sandwich press is a reliable choice for those in regions where standard voltage may not be available, thus expanding your market reach without the need for separate product lines.

With the rise of health-conscious consumers, there’s a growing demand for kitchen appliances that make it easy to prepare nutritious meals at home. Our sandwich press not only allows for the creation of delicious sandwiches but also supports a healthier lifestyle. It’s a simple addition to any kitchen, encouraging customers to make their own meals, which can lead to increased customer loyalty and repeat purchases.

The ease of use of our sandwich press is another key advantage. Its intuitive design means that even those who aren’t tech-savvy can enjoy the convenience of a perfectly toasted sandwich. This user-friendly aspect can reduce customer service inquiries and increase satisfaction, as customers appreciate the simplicity of the product.

Customization is a powerful tool in marketing. Our sandwich press offers the opportunity for your brand to stand out. With various colors, finishes, and even the option to add your logo, you can create a unique product that resonates with your target audience. This level of personalization can make your sandwich press a sought-after item, increasing its appeal and potentially boosting sales.

In the age of social media and online reviews, the importance of product quality cannot be overstated. Our sandwich press is built to last, with high-quality materials and durable construction. This reliability ensures that customers will not only enjoy their purchase but also recommend it to others, which can lead to organic growth and positive word-of-mouth marketing.

Energy efficiency is a growing concern for consumers and businesses alike. Our dual voltage sandwich press is designed to be energy-efficient, reducing utility costs for your customers while also aligning with their eco-friendly values. This feature can be a strong selling point, especially in areas where energy conservation is a priority.

The compact and space-saving design of our sandwich press is perfect for small kitchens, apartments, and even outdoor settings. This versatility means that it’s not just for home use; it can also be a hit in the foodservice industry, from cafes to camping trips. By offering a product that can cater to various environments, you’re appealing to a wider range of customers.

Our sandwich press also has the potential to be a cross-selling opportunity. It can be paired with other kitchen gadgets or accessories, creating a bundle that adds value to the customer’s purchase. This bundling strategy can increase the average transaction value and potentially lead to higher profit margins.

Lastly, the trend towards home entertaining and DIY cooking has been on the rise. Our sandwich press is an excellent tool for creating homemade snacks and meals, which are increasingly popular at social gatherings. By offering a product that encourages home cooking, you’re tapping into a market that values creativity and personal touch in their dining experiences.

In summary, our 120V/240V dual voltage sandwich press is a multifaceted product that offers numerous benefits to enhance your business. From its broad market appeal and health-conscious design to its user-friendliness and customization options, this sandwich press is a valuable asset that can drive sales, build brand loyalty, and keep your customers coming back for more.

I’ve been using this sandwich press for a couple of months now, and it’s a game-changer in my kitchen. The dual voltage feature is fantastic, allowing me to use it in different countries without worrying about compatibility issues. It’s sleek, easy to clean, and the even heat distribution ensures my sandwiches are perfectly toasted every time. I’ve received so many compliments from friends and family that I’ve even started making extra for them to take home. It’s a hit!

My business has seen a significant boost since we started using this 120V/240V sandwich press. It’s a great addition to our menu, offering a unique twist on a classic favorite. The versatility of the press allows us to experiment with different bread types and fillings, making it a favorite among our customers. Plus, it’s so easy to use and clean, which has saved us time and effort in the kitchen. I can’t recommend it enough!

I was skeptical at first about investing in a dual voltage sandwich press, but it’s turned out to be one of the best decisions I’ve made for my café. The press is durable and the heat is consistent, which is crucial for keeping our sandwiches looking and tasting great. Our customers have noticed the improvement, and the word-of-mouth referrals have been incredible. It’s a must-have for any café looking to offer a high-quality, unique sandwich option.

I was hesitant to switch from my old sandwich press to this new dual voltage model, but I’m so glad I did. The design is sleek and modern, and the press itself is a breeze to use. It heats up quickly, and the evenness of the toast is unparalleled. I’ve noticed a noticeable increase in customer satisfaction, and I’ve even started using it to make other items like grilled cheese and paninis. It’s a versatile tool that has made my life in the kitchen so much easier.

The feedback from our customers has been overwhelmingly positive since we introduced the 120V/240V sandwich press. It’s a hit with everyone, from the kids who love their grilled cheese to the adults who appreciate a good panini. The press is a great conversation starter, and it’s even become a staple at our office lunch gatherings. We’ve had several customers ask if they can purchase their own, which is a testament to how much they enjoy using it.

I was looking for a sandwich press that could keep up with the high demand in our busy restaurant, and this dual voltage model has exceeded my expectations. It’s robust, easy to maintain, and the results are consistently delicious. Our customers have taken notice, and we’ve seen an increase in the number of people ordering our sandwiches. It’s a small investment that has paid off big time for our business.

I’ve been using this sandwich press for a few months now, and it’s become an essential part of my home kitchen. The ability to use it in different countries has been a huge convenience, and the quality of the toasts is top-notch. It’s also surprisingly easy to clean, which is a big plus for me. I’ve shared it with friends, and they’re all impressed with how well it works. It’s a fantastic addition to any kitchen.

Our family loves making sandwiches at home, and this 120V/240V sandwich press has made the process even more enjoyable. It’s so easy to use, and the results are always perfect. The even heat distribution ensures that every piece of bread gets toasted just right. It’s also a great way to get the kids involved in the cooking process. We’ve had so much fun experimenting with different fillings, and the press has become a favorite among all of us.

In my catering business, presentation is key, and this sandwich press has been a game-changer. The ability to create beautifully toasted sandwiches with even browning has helped me to deliver a high-quality product that stands out from the competition. The dual voltage feature means I can use it anywhere in the world, which is incredibly convenient. It’s a small investment that has had a big impact on my business.

In the ever-evolving world of kitchen appliances, the sandwich press has become a staple in home kitchens and commercial settings alike. As technology advances and consumer preferences shift, the future of sandwich presses looks promising, with several key trends and innovations on the horizon.

The integration of smart technology is set to revolutionize the way sandwich presses are used. Imagine a sandwich press that not only ensures perfect browning but also offers customizable settings for various types of bread and fillings. With the help of built-in sensors and smart connectivity, these presses could provide real-time feedback and even suggest recipes based on the user’s preferences.

Energy efficiency is another area where we can expect significant advancements. As sustainability becomes a greater concern for consumers and businesses, the next generation of sandwich presses may feature energy-saving modes and materials that reduce their carbon footprint. This not only benefits the environment but also cuts down on long-term operating costs.

Portability is a growing trend, especially in the commercial sector. Compact, lightweight sandwich presses that can be easily moved from one location to another are becoming increasingly popular. This allows businesses to adapt to changing customer needs and to cater to outdoor events or temporary pop-up shops without the hassle of a fixed kitchen setup.

Designs are also expected to become more diverse and appealing. With the rise of personalization, sandwich presses may come in various colors, shapes, and even with unique features like built-in timers or LED lighting to enhance the cooking experience. This aesthetic evolution could help the sandwich press stand out as a stylish addition to any kitchen.

The rise of health-conscious consumers has led to a demand for healthier sandwich options. Future sandwich presses might include features that make it easier to prepare nutritious sandwiches, such as non-stick surfaces that reduce the need for excessive oil and fat, or even built-in steam functions to add moisture without adding calories.

Innovation in materials is another area to watch. Lightweight yet durable materials like high-quality stainless steel or advanced polymers could make sandwich presses more robust and easier to clean. This not only improves the user experience but also extends the lifespan of the appliance.

Safety features are always a priority, and the future of sandwich presses is likely to see enhancements in this area as well. Features like automatic shut-off timers, temperature control, and child-proof locks could become standard, ensuring that the appliance is both convenient and safe for all users.

Customizability is also on the rise. Users might be able to choose from different press plates, each designed for different types of bread and fillings, allowing for a wide variety of sandwich options. This modular approach would provide flexibility and cater to the diverse tastes of consumers.

As the world becomes more connected, the potential for remote monitoring and control of sandwich presses is significant. Users could check the status of their sandwich press from their smartphones, receive alerts for maintenance, and even preheat the appliance before they arrive home.

Lastly, the impact of social media and online communities on consumer preferences cannot be overlooked. The sandwich press of the future may be influenced by the latest trends shared on platforms like Instagram and TikTok, where the visual appeal of the final product plays a crucial role in its popularity.

In summary, the future of sandwich presses is bright, with a focus on smart technology, sustainability, portability, design, health, safety, customizability, connectivity, and social media influence. These trends suggest that the sandwich press is not just a kitchen tool but a symbol of the ever-changing landscape of modern living.