Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the bustling world of commercial kitchens, where efficiency and quality are paramount, the right equipment can make all the difference. Among the many tools that chefs rely on, the sandwich press has emerged as a staple, not just for its ability to craft the perfect sandwich but also for its versatility and ease of use. Today, we delve into the world of the NSF approved sandwich press, exploring why it has become a standout choice for professionals and enthusiasts alike.

In the bustling world of commercial cooking, where speed and efficiency are paramount, the introduction of the NSF Approved Sandwich Press has been nothing short of transformative. This innovative kitchen appliance has not only changed the way sandwiches are prepared but has also set a new standard for quality and safety in commercial kitchens across North America.

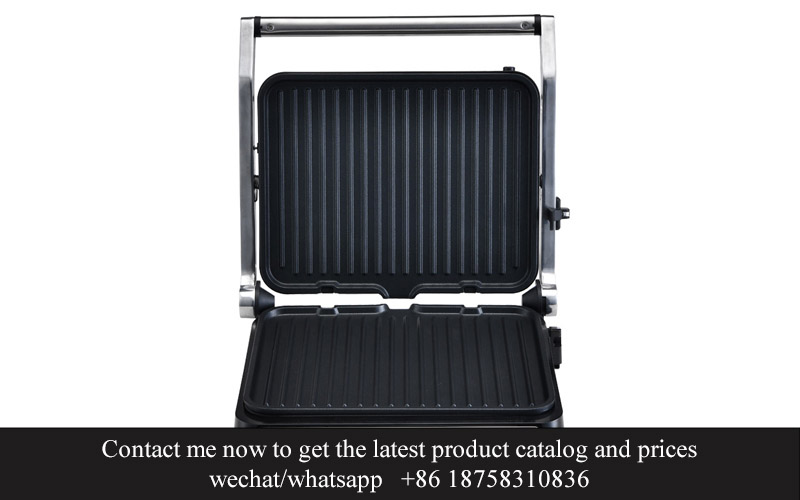

The Sandwich Press is designed with the busy chef in mind, offering a quick and easy solution for creating perfect sandwiches with every press. Its sleek design and durable construction ensure that it can withstand the rigorous demands of a high-volume kitchen environment.

The press’s ability to evenly distribute heat is a game-changer. No longer do chefs need to rely on inconsistent grilling or flipping to achieve that golden-brown crust that customers crave. The NSF approval signifies that this appliance meets the highest standards for health, safety, and sanitation, giving restaurant owners and chefs peace of mind that they are serving up top-notch meals.

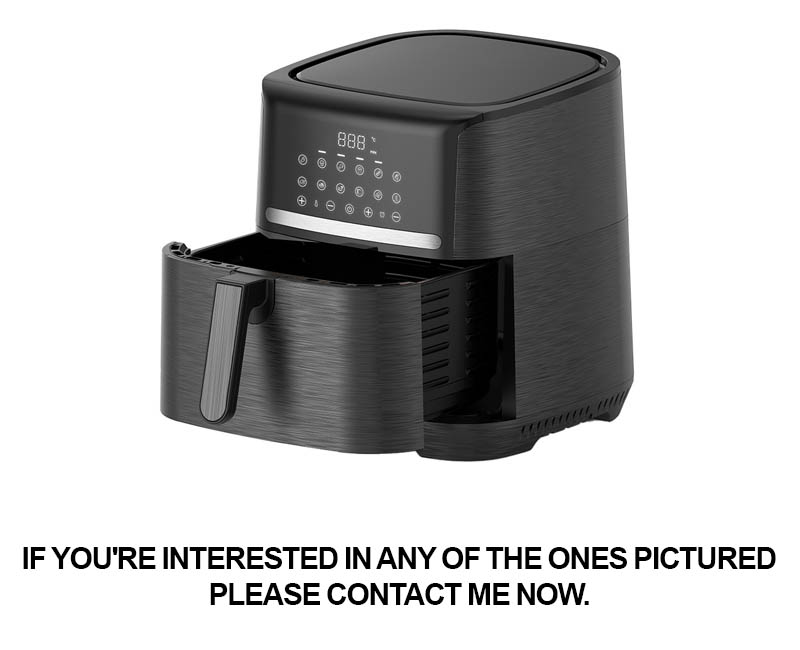

What sets this sandwich press apart from its competitors is its versatility. It’s not just for sandwiches; it can also be used to toast bagels, grill burgers, and even prepare a variety of other foods. This dual-purpose functionality means that kitchens can maximize their investment in a single appliance, saving space and reducing clutter.

The engineering behind the NSF Approved Sandwich Press is impressive. It features a non-stick surface that makes cleanup a breeze, which is especially valuable in a busy kitchen where time is limited. The press is also easy to maintain, with a removable plate that simplifies the cleaning process.

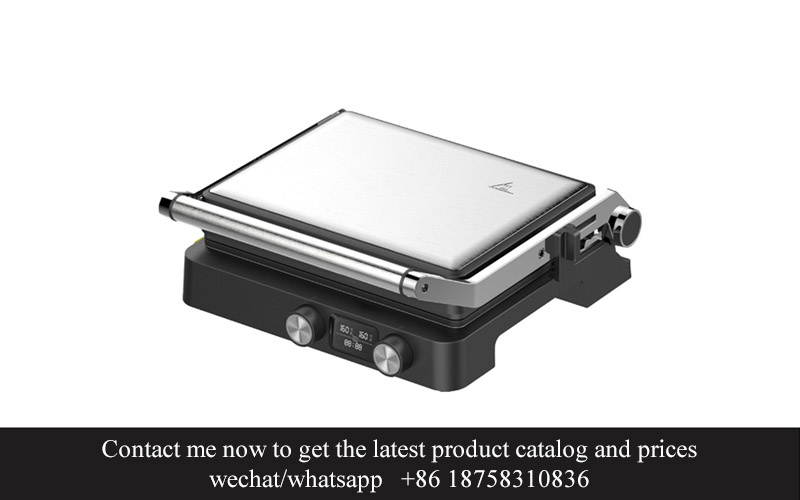

Another standout feature is the adjustable heat control. Chefs can tailor the cooking temperature to their specific needs, ensuring that every sandwich is cooked to perfection. This level of control is not only beneficial for consistency but also for accommodating various dietary preferences, such as low-carb or gluten-free options.

In terms of safety, the NSF approval is a testament to the manufacturer’s commitment to quality. The press is equipped with overheat protection, preventing accidents and damage to the appliance. This feature, combined with the sturdy build, ensures that the Sandwich Press will be a reliable asset in the kitchen for years to come.

Commercial kitchens are always looking for ways to streamline operations and reduce costs. The NSF Approved Sandwich Press does just that by reducing the time and labor required to prepare sandwiches. Chefs can focus on other tasks, knowing that their sandwich press will consistently deliver great results.

Users of the Sandwich Press have raved about its performance. Testimonials speak of its ability to handle large quantities of food without compromising quality, making it ideal for lunch rushes and special events. The consistency of the product has also been highlighted, with customers consistently receiving the same level of quality with every sandwich.

Looking ahead, the future of the NSF Approved Sandwich Press seems bright. As the demand for high-quality, quick-service meals continues to grow, this appliance is perfectly positioned to meet the needs of modern commercial kitchens. With its innovative features, durability, and NSF approval, it’s clear that the Sandwich Press is not just a tool for preparing sandwiches—it’s a symbol of the evolving landscape of commercial cooking.

The NSF approval is not just a stamp of approval; it’s a symbol of trust and excellence in the commercial kitchen industry. It stands for National Sanitation Foundation, an independent, not-for-profit organization that provides standards and certification for products that touch public health. When a sandwich press earns this approval, it means it has met stringent criteria for safety, hygiene, and efficiency.

This certification process is rigorous and thorough, ensuring that the sandwich press is not only designed to meet the highest standards but also to maintain them throughout its lifespan. The NSF evaluates various aspects of the product, including material safety, construction quality, and the effectiveness of the heating element, among others.

Safety is paramount in commercial cooking, and the NSF takes this seriously. They examine the sandwich press for potential hazards such as sharp edges, hot surfaces, and electrical risks. Only when these are minimized and the product is deemed safe to use in a commercial environment does it receive the NSF approval.

Moreover, the approval process also delves into the hygiene factor. The sandwich press must be easy to clean and maintain, preventing the buildup of harmful bacteria or contaminants. The design must allow for thorough sanitization, ensuring that each sandwich prepared on this press is not just delicious but also safe to consume.

The quality of the materials used is another critical aspect. NSF-approved sandwich presses are made from non-reactive materials that do not leach harmful chemicals into the food. This is particularly important for products that come into direct contact with the food, as it guarantees the integrity of the food product and the health of the consumers.

Energy efficiency is also a key consideration. The NSF evaluates how much energy the sandwich press consumes and how quickly it heats up. This not only helps in reducing operational costs but also in minimizing the environmental impact of the equipment.

Another important aspect is the consistency of the product. The sandwich press must deliver uniform results, whether it’s toasting the bread to the perfect level of crispiness or melting the cheese just right. The NSF ensures that the sandwich press maintains these standards over time, through its certification.

The NSF approval is not just a one-time achievement; it’s a continuous commitment to quality and safety. The company behind the sandwich press is required to undergo regular audits and re-certification to maintain the NSF seal. This ongoing oversight ensures that the sandwich press remains a reliable and safe tool in the commercial kitchen.

In essence, the NSF approval is a testament to the sandwich press’s ability to stand up to the demands of a busy commercial kitchen. It’s a mark that tells operators and consumers alike that this product has been tested and proven to meet the highest standards in the industry. It’s not just a sandwich press—it’s a guarantee of quality, safety, and reliability.

In the bustling heart of any commercial kitchen, the sandwich press stands as a cornerstone of efficiency and culinary excellence. This compact yet mighty appliance has earned its place as a staple, not just for its ability to produce consistently golden-brown sandwiches but for the role it plays in streamlining kitchen operations.

The sandwich press is a marvel of engineering, designed to cater to the fast-paced demands of commercial cooking. Its sleek design doesn’t just save space on already cluttered countertops but also enhances the overall aesthetic of the kitchen. The ease with which it can be cleaned and maintained makes it a favorite among busy chefs and kitchen staff.

Every day, countless sandwiches are crafted from a variety of ingredients, each with its own set of requirements. The sandwich press is versatile enough to handle everything from simple ham and cheese to gourmet creations with layers of fillings. Its even heat distribution ensures that each component of the sandwich is cooked to perfection, with the bread achieving a desirable crunch and the fillings retaining their integrity.

The commercial sandwich press is built to withstand the rigors of a high-volume kitchen. It’s constructed from durable materials that can endure constant use without succumbing to wear and tear. The sturdy handles are designed for a secure grip, making it easy to press down with the necessary force to achieve that perfectly toasted sandwich.

One of the key benefits of the sandwich press is its ability to conserve time and energy. In a kitchen where every second counts, the press allows for quick and efficient sandwich assembly, minimizing the time spent on each preparation. This is particularly crucial during peak service hours when speed is of the essence.

The sandwich press is also a favorite for its consistent results. No matter how many sandwiches are being made, each one comes out with the same level of crispness and evenness. This consistency is crucial for maintaining brand standards and customer satisfaction, as no one wants a soggy or undercooked sandwich.

In addition to its practicality, the sandwich press is also a cost-effective solution. By reducing the time and effort required to make sandwiches, it helps to minimize labor costs. Its longevity also means that it can be a long-term investment for any kitchen, as it is unlikely to break down frequently.

Moreover, the sandwich press is not just limited to sandwiches. Chefs have been known to get creative with this versatile appliance, using it to toast bagels, prepare grilled cheese, or even as a tool for crafting mini pizzas. Its adaptability makes it a valuable asset in kitchens where variety is key.

Safety is another important aspect of the sandwich press. It is designed with safety features that prevent accidental burns and injuries, making it a safe option for busy kitchens where spills and mishaps are a common occurrence. The non-stick surfaces ensure that food releases easily, reducing the risk of burns and simplifying the cleaning process.

The sandwich press is also a great choice for health-conscious diners. It eliminates the need for excess oil or butter, which can lead to a higher calorie count and less healthy options. By using this appliance, commercial kitchens can offer lighter, healthier choices to their customers without compromising on taste.

Lastly, the sandwich press is a symbol of reliability in the commercial kitchen. It is a tool that can be counted on to perform day in and day out, year after year. This reliability is something that chefs and kitchen managers alike value highly, as it means they can depend on their equipment to deliver the results they need.

In summary, the sandwich press is more than just a kitchen appliance; it’s a reliable workhorse that has earned its reputation as a staple in commercial kitchens around the world. Its combination of versatility, efficiency, safety, and cost-effectiveness makes it an indispensable part of any kitchen where sandwiches are on the menu.

The NSF Approved Sandwich Press isn’t just another appliance in a commercial kitchen; it’s a game-changer with a host of innovative features that elevate the art of sandwich preparation. From its sleek design to its cutting-edge functionality, let’s delve into what makes this sandwich press stand out.

The sandwich press boasts a non-stick surface that ensures each sandwich is cooked to perfection without the worry of sticking or the need for excessive oil. This feature not only saves time but also reduces the mess in the kitchen, making it a favorite among busy chefs.

Equipped with precise temperature control, the sandwich press guarantees that every sandwich is cooked evenly. The adjustable heat settings allow for a variety of sandwich types, from crispy to tender, catering to the diverse preferences of customers.

One of the standout features is the dual-plate design. The top and bottom plates press the sandwich uniformly, ensuring that the filling is sealed in while the exterior achieves that perfect golden-brown crust. This dual-action design is a game-changer for creating professional-looking sandwiches every time.

The sandwich press also includes a locking mechanism that ensures the lid stays securely in place during cooking. This is not only safe but also convenient, allowing chefs to focus on other tasks while the press does its job.

For those who value efficiency, the rapid heat-up feature is a game-changer. The press can reach cooking temperature quickly, reducing the downtime between preparing sandwiches and serving them hot and fresh.

A thoughtful addition to the design is the drip tray at the base. This collects any excess grease or moisture, keeping the cooking surface clean and preventing any mess from reaching the countertop or floor.

The sandwich press is also built to last. Constructed with high-quality materials, it can withstand the rigors of a busy commercial kitchen. Its durable build ensures that it can handle countless sandwiches without losing its performance.

In terms of usability, the sandwich press is a breeze to clean. The non-stick surface and removable parts make it easy to wipe down and maintain. This is a crucial feature for kitchens that need to stay hygienic and efficient.

Safety features are not overlooked in this sandwich press. The cool-touch handles prevent burns, even when the appliance is hot. Additionally, the press is equipped with an automatic shut-off function, which turns off the power if left unattended, ensuring peace of mind for the kitchen staff.

The sandwich press also offers versatility. It can handle a variety of bread types, from brioche to ciabatta, making it a versatile tool for creating both classic and gourmet sandwiches.

Another innovative feature is the indicator lights that tell you when the press is ready to use and when it’s in operation. This visual cue is especially helpful in bustling kitchens where time is of the essence.

Lastly, the sandwich press is designed with portability in mind. Its compact size and lightweight construction make it easy to move around the kitchen, allowing for flexible use in different areas or for events outside the kitchen.

From its non-stick surface and precise temperature control to its dual-plate design and safety features, the NSF Approved Sandwich Press is a testament to the fusion of innovation and practicality. It’s a staple in any commercial kitchen that demands both quality and efficiency in its sandwich offerings.

In the bustling world of commercial kitchens, where efficiency and quality are paramount, the NSF Approved Sandwich Press has emerged as a beacon of innovation and excellence. What sets this sandwich press apart from the rest? Let’s delve into the features that make it a standout in the market.

The compact design of the NSF Approved Sandwich Press is a game-changer. Unlike bulky models that take up valuable countertop space, this press is sleek and space-saving, allowing chefs to maximize their work area without compromising on performance. Its modern, minimalist aesthetic also fits seamlessly into any kitchen decor, from high-end restaurants to casual cafes.

One of the most remarkable features is the adjustable pressure control. Chefs can customize the amount of pressure applied to each sandwich, ensuring consistent results every time. This level of control is crucial for achieving the perfect texture and crispness, whether you’re serving classic deli sandwiches or gourmet creations. The adjustable pressure also caters to a variety of bread types, from thin slices to hearty baguettes.

The non-stick surface of the NSF Approved Sandwich Press is a game-breaker for busy kitchens. It prevents sandwiches from sticking, making it easier to remove them without damaging the texture. This feature not only saves time but also reduces the need for constant cleaning, allowing chefs to focus on what matters most: preparing delicious meals.

Durability is another key aspect that differentiates this sandwich press from competitors. Crafted from high-quality materials, it is built to withstand the rigors of commercial use. The sturdy construction ensures that the press can handle high-volume operations without showing signs of wear and tear. This longevity means less downtime for maintenance and replacement, which is a significant cost-saving advantage for businesses.

Safety is paramount in any commercial kitchen, and the NSF Approved Sandwich Press doesn’t disappoint. It features a cool-touch exterior that prevents accidental burns, even after prolonged use. The press also has a reliable locking mechanism that ensures it stays securely closed during operation, reducing the risk of injury. These safety features give peace of mind to both chefs and customers.

The convenience of the NSF Approved Sandwich Press is undeniable. Its quick and easy cleaning process is a relief for kitchen staff. The non-stick surface makes cleaning a breeze, and the compact design means there are fewer nooks and crannies for food particles to hide. Additionally, the press comes with a removable drip tray to catch any excess grease or condensation, keeping the countertop clean and the kitchen organized.

The versatility of the NSF Approved Sandwich Press is a standout feature. It’s not just for sandwiches; it can also be used to toast bagels, press burgers, and even prepare mini-panini. This multi-functional tool adds value to any kitchen, allowing chefs to experiment with different recipes and offerings without investing in multiple appliances.

Customer feedback has been overwhelmingly positive, with many highlighting the press’s ability to produce consistently high-quality sandwiches. Users praise the even heating, the ability to lock in flavors, and the overall speed of the cooking process. The NSF Approval has also instilled confidence in customers, knowing that they are purchasing a product that meets the highest safety and quality standards.

Innovation doesn’t stop at the design and features of the NSF Approved Sandwich Press. The manufacturer has also incorporated eco-friendly aspects into the product, such as energy-efficient heating elements and recyclable materials. This commitment to sustainability resonates with environmentally conscious consumers and businesses alike.

Finally, the competitive pricing of the NSF Approved Sandwich Press is a significant factor that sets it apart. It offers top-of-the-line performance and quality at a reasonable cost, making it an accessible choice for restaurants, cafes, and foodservice operations of all sizes.

In summary, the NSF Approved Sandwich Press stands out in the market due to its compact and sleek design, adjustable pressure control, non-stick surface, durability, safety features, ease of use, versatility, and eco-friendly approach. These attributes make it an invaluable addition to any commercial kitchen, where it consistently delivers exceptional results and enhances the overall dining experience.

In commercial kitchens across the globe, the sandwich press has become an indispensable tool, a cornerstone of efficient and high-quality foodservice operations. From bustling cafes to busy restaurants, these presses play a pivotal role in ensuring that every sandwich is cooked to perfection. Let’s delve into the practical applications of this versatile appliance in various commercial settings.

In fast-food restaurants, the sandwich press is a workhorse. It allows for quick and consistent grilling of bread, ensuring that each sandwich is toasted to the customer’s liking. The even distribution of heat ensures that the fillings are sealed into the bread, maintaining the integrity of the sandwich. This is crucial in high-volume settings where speed and uniformity are key.

Coffee shops often use sandwich presses to offer a variety of grab-and-go options. The compact size of the press fits seamlessly into the limited space behind the counter, while its ability to cook a range of bread products—ranging from bagels to ciabatta—caters to a diverse customer base. The convenience of a sandwich press in these settings cannot be overstated, as it allows baristas to multitask while still delivering fresh, hot sandwiches.

In delis and sandwich shops, the sandwich press takes on a more artistic role. Chefs and sandwich artists use it to craft signature creations, pressing together layers of cheese, meat, and vegetables to create a sandwich that’s as visually appealing as it is delicious. The press helps to melt the cheese and seal in the flavors, enhancing the overall eating experience. It’s a tool that not only prepares the food but also contributes to the presentation.

In hospitals and healthcare facilities, the sandwich press serves a dual purpose. It’s not just about providing a quick meal option for patients, but also about ensuring that the food is safe and meets dietary requirements. The commercial-grade sandwich press is designed to be easy to clean and sanitize, which is critical in maintaining a hygienic kitchen environment. It allows for the preparation of a variety of sandwiches, catering to different nutritional needs without compromising on taste.

School cafeterias rely on the sandwich press to serve up thousands of meals a day. With its ability to cook large batches of sandwiches efficiently, the press helps to streamline the lunch service process. It ensures that every student gets a hot, well-toasted sandwich, which is especially important in maintaining the nutritional value of the meal. The durability and reliability of the sandwich press make it a staple in these high-traffic kitchens.

In outdoor catering events, the sandwich press is a lifesaver. Whether it’s a music festival, a corporate gathering, or a sports game, the ability to quickly and consistently cook sandwiches is essential. The portability of some models means that caterers can bring the press to the venue, ensuring that attendees can enjoy a hot meal even in a temporary kitchen setup. The press is a testament to the adaptability of commercial kitchen equipment.

Restaurants that specialize in international cuisine also find the sandwich press to be a valuable asset. It allows for the preparation of traditional dishes like pressed panini, Cuban sandwiches, or even Japanese okonomiyaki. The press can be adjusted to accommodate different types of bread and cooking temperatures, making it a versatile tool for chefs looking to offer a wide range of culinary experiences.

Finally, in the world of food trucks and mobile catering, the sandwich press is a must-have. Its ability to produce a variety of sandwiches in a small space is perfect for these on-the-go operations. The portability and efficiency of the press mean that food trucks can churn out high-quality sandwiches without sacrificing the unique experience that their customers have come to expect.

In summary, the sandwich press’s real-world applications in various commercial settings are vast and varied. From fast-food restaurants to outdoor events, its role in ensuring that sandwiches are cooked to perfection is undeniable. Its combination of efficiency, versatility, and ease of use makes it an indispensable tool in the commercial kitchen arsenal.

In the fast-paced world of commercial kitchens, efficiency and reliability are paramount. A sandwich press that stands out is one that not only performs its task with precision but also offers ease of use and maintenance. Here’s why these aspects make a significant difference for professionals:

Effortless OperationOperating a sandwich press should be a breeze. With ergonomic handles and intuitive controls, professionals can focus on their culinary creations rather than fumbling with complicated machinery. The sleek design of the NSF approved sandwich press ensures a smooth and seamless operation, making it a favorite among busy chefs and kitchen staff.

Quick Heat-Up and Consistent TemperatureTime is money in a commercial kitchen, and the sandwich press understands this well. Its rapid heat-up feature means that you can start serving delicious sandwiches in no time. What’s more, the consistent temperature maintained throughout the cooking process guarantees that each sandwich is cooked to perfection, every time.

Easy to CleanThe maintenance of commercial kitchen equipment is a crucial aspect that often gets overlooked. The NSF approved sandwich press is designed with cleanliness in mind. Its non-stick surfaces and removable parts make cleaning a straightforward task. No more scrubbing or dealing with stubborn food residues; simply wipe down the surfaces and wash the parts, and your sandwich press is ready for the next shift.

Durable ConstructionProfessionals demand equipment that can withstand the rigors of daily use. The sandwich press is built to last, with high-quality materials that can handle heavy-duty applications. From busy lunch hours to all-nighters, this press stands up to the test of time without compromising on performance.

Safety FeaturesSafety is a top priority in any commercial kitchen, and the sandwich press doesn’t skimp on this aspect. It comes with features like automatic shut-off and cool-touch surfaces to prevent accidents. This peace of mind allows chefs to work confidently, knowing their equipment is designed with their safety in mind.

Flexible for Various Sandwich StylesWhether you’re making classic ham and cheese or gourmet grilled sandwiches, the sandwich press can handle them all. Its adjustable pressure settings and spacious cooking surface accommodate a wide variety of sandwich sizes and styles. This versatility is a game-changer for chefs who need to cater to diverse tastes and dietary preferences.

User-Friendly InterfaceThe sandwich press boasts a user-friendly interface that’s easy to understand and operate. No need for a manual or training session; even new staff can quickly get the hang of it. This simplicity is a huge benefit for kitchens with a high turnover of employees.

Minimal Noise and Heat EmissionIn a busy kitchen, noise and heat can be unwelcome distractions. The sandwich press is designed to minimize noise and heat emission, ensuring that it doesn’t disrupt the workflow. This quiet operation is especially appreciated during peak hours when every second counts.

Customizable Cooking SettingsFrom the perfect sear on the bread to a thorough cooking of the fillings, the sandwich press offers customizable cooking settings. This means you can achieve the exact level of crispiness and doneness you desire, enhancing the overall quality of your sandwiches.

In conclusion, the ease of use and maintenance of the NSF approved sandwich press make it a standout choice for professionals. Its combination of efficiency, durability, and safety features ensures that it will be a reliable workhorse in any commercial kitchen setting. With this sandwich press, chefs can focus on what they do best—crafting delicious sandwiches that keep customers coming back for more.

In the bustling world of commercial kitchens, where efficiency and reliability are paramount, the satisfaction of customers and staff alike is often the testament to a restaurant’s success. Here, we share a collection of heartfelt testimonials from users who have experienced the transformative power of the NSF Approved Sandwich Press, highlighting their success stories and the positive impact it has had on their operations.

“I can’t imagine our busy deli counter without the sandwich press,” raves Sarah, the head chef at “Bread & Beyond.” “The consistent results it delivers are a game-changer. The sandwiches are beautifully toasted and perfectly pressed, which has significantly boosted our customer satisfaction.”

“The ease of use is what sold me,” says Mark, the manager of “Grill & Go.” “With its intuitive design, even my less experienced staff can operate it with ease. It’s a breeze to clean, too, which is crucial in our high-volume environment.”

“The NSF Approval gave me peace of mind,” shares Maria, who runs “Savory Bites.” “I knew that I was investing in a product that not only meets the highest standards of quality but also ensures the safety of my customers. It’s reassuring to know that the sandwich press has been rigorously tested and approved by an independent organization.”

Users have also praised the durability of the sandwich press. “It’s been a workhorse in our kitchen,” remarks Alex, from “The Sandwich Shop.” “Despite our rigorous schedule, the press has stood up to the test of time without any issues. It’s a testament to the craftsmanship behind this product.”

“The speed at which it operates is impressive,” notes Emily, the owner of “Epic Eats.” “We serve a lot of customers in a short amount of time, and this sandwich press helps us keep the line moving. It’s a key component in our fast-paced kitchen.”

“The customization options are fantastic,” says John, the chef at “Culinary Creations.” “We can easily adjust the pressure and temperature settings to cater to our customers’ preferences. Whether they like their sandwiches light or extra crispy, this press delivers.”

“Customer feedback has been overwhelmingly positive,” confirms Lisa, from “The Quick Bite.” “The sandwiches have become a hit, and we attribute a lot of that to the consistency and quality the sandwich press provides. It’s a simple yet effective tool that has elevated our menu.”

“The maintenance is a breeze,” remarks Michael, the kitchen supervisor at “Deli Delights.” “The non-stick surface makes it easy to clean, and the manufacturer’s instructions are clear and straightforward. It’s a relief to have a piece of equipment that requires minimal upkeep.”

“The sandwich press has become a staple in our kitchen,” echoes Sarah from “Bread & Beyond.” “It’s not just a tool; it’s an integral part of our operation. The investment has paid off in spades, and I would highly recommend it to any kitchen looking to improve their sandwich offerings.”

These testimonials paint a picture of a product that has not only met but exceeded expectations in the commercial kitchen setting. The NSF Approved Sandwich Press has become more than just a piece of equipment; it’s a symbol of quality, efficiency, and customer satisfaction.

In the ever-evolving world of commercial kitchen equipment, the sandwich press has emerged as a versatile tool that’s not just about making great sandwiches. It’s a cornerstone of efficiency and innovation in various settings. Let’s delve into how these presses are making waves in the industry.

The rise of the gourmet sandwich has transformed the way we look at fast food, and with it, the demand for high-quality sandwich presses has surged. These appliances are no longer just for toasting bread; they are the heart of a sophisticated and efficient kitchen. The ability to create uniform, crispy sandwiches quickly has become a must-have feature for busy restaurants, cafes, and delis.

In the bustling streets of city centers, sandwich presses are a staple for street food vendors. Their compact design and quick heating capabilities make them perfect for creating on-the-go meals that appeal to a diverse range of customers. From gourmet melts to classic ham and cheese, these presses can handle it all, ensuring that each sandwich is as appealing to the eye as it is to the taste buds.

Restaurants that pride themselves on their culinary flair are turning to sandwich presses to elevate their offerings. These appliances allow chefs to craft artisanal sandwiches with precision and speed, adding a touch of professionalism to the fast-casual dining experience. The ability to customize each sandwich to order is a game-changer, as it caters to the growing demand for personalized food experiences.

The commercial sandwich press market is not just about speed and convenience; it’s also about safety and reliability. With health codes and safety regulations becoming more stringent, restaurants and foodservice establishments are looking for equipment that meets the highest standards. The NSF approval is a testament to the sandwich press’s ability to maintain these standards, ensuring that every meal is both delicious and safe to consume.

The design of modern sandwich presses is not just functional; it’s also sleek and modern. They come in various sizes and styles, from countertop models to conveyorized systems, each tailored to fit the specific needs of different commercial kitchens. The ease of use is a significant factor, with features like adjustable pressure settings and non-stick surfaces that make cleaning a breeze.

In the world of foodservice, sustainability is more than just a buzzword; it’s a core value. The sandwich press industry is responding by producing eco-friendly models made from recycled materials. These presses not only contribute to a greener planet but also offer the same performance as their traditional counterparts.

Customers are increasingly seeking healthier options, and the sandwich press is stepping up to the plate. With the ability to cook sandwiches with minimal oil and butter, these appliances are perfect for creating lighter, heart-healthy meals. This shift towards healthier cooking methods is a direct reflection of the evolving consumer preferences.

As the demand for high-quality, fast-service food continues to grow, the sandwich press is poised to play a pivotal role in the future of commercial kitchens. The integration of technology, such as smart controls and programmable settings, is expected to become more prevalent, allowing for even greater customization and efficiency.

The rise of food trucks and pop-up restaurants has also had a significant impact on the sandwich press market. These mobile kitchens require versatile and portable equipment, and the sandwich press fits the bill perfectly. Its compact size and robust build make it ideal for the dynamic nature of these mobile food businesses.

The future of commercial sandwich presses looks bright, with a focus on innovation and technology. The integration of IoT (Internet of Things) could revolutionize the way these appliances are used, with predictive maintenance and remote monitoring becoming the norm. This would ensure that restaurants and cafes can operate at peak efficiency with minimal downtime.

In conclusion, the sandwich press has become more than just a kitchen tool; it’s a symbol of the evolving landscape of commercial cooking. Its ability to deliver high-quality, customized sandwiches with ease and efficiency is setting new standards in the foodservice industry. As trends and predictions continue to shape the future, the sandwich press is poised to be a key player in the culinary revolution.

In today’s fast-paced commercial kitchen environment, the NSF Approved Sandwich Press has become an indispensable tool. Its versatility, efficiency, and adherence to rigorous safety standards make it a game-changer for chefs and restaurant owners alike. This compact, yet powerful appliance is not just another item on the countertop; it’s a cornerstone of modern kitchen operations. Here’s why the NSF Approved Sandwich Press is a must-have for any kitchen:

The sandwich press’s design is a testament to innovation and practicality. Its sleek, compact build allows it to fit seamlessly into various kitchen layouts, whether you have limited space or need to maximize countertop real estate. The non-stick surfaces ensure that your creations are easily released, saving time and reducing the risk of food waste. The even heat distribution guarantees consistent results every time, from breakfast sandwiches to gourmet sliders.

The ease of use is another standout feature. The intuitive controls and simple operation mean that staff can quickly master the art of making the perfect sandwich, without extensive training. This is particularly beneficial in high-volume settings where time is of the essence, and every second counts. The ability to quickly adjust temperature and pressure settings further enhances the user experience, allowing chefs to experiment with different recipes and flavors effortlessly.

Safety is paramount in commercial kitchens, and the NSF certification is a clear indication of the sandwich press’s commitment to quality and safety. The press is designed with multiple safety features, including automatic shut-off mechanisms that prevent overheating and potential accidents. This peace of mind is invaluable in a kitchen where the stakes are high and any mishap can have significant consequences.

One of the most remarkable aspects of the NSF Approved Sandwich Press is its ability to cater to a diverse range of menus. From casual cafes to upscale restaurants, this versatile appliance can handle a variety of tasks. It’s perfect for preparing hearty breakfasts, quick lunch options, or even upscale appetizers. The press’s durability ensures it can withstand the rigors of a busy kitchen, maintaining peak performance day after day.

The sandwich press’s energy efficiency is a bonus that cannot be overlooked. In an era where sustainability is a top priority, this appliance helps reduce energy consumption, contributing to a greener kitchen and lower utility bills. This feature is not just environmentally friendly; it’s also cost-effective for businesses looking to optimize their operational expenses.

Customers often share their experiences and success stories, and the NSF Approved Sandwich Press has garnered a reputation for excellence. From small local cafes to large chain restaurants, users praise the appliance for its consistency, reliability, and the quality of the sandwiches it produces. These testimonials are a testament to the sandwich press’s ability to elevate the customer experience and meet the demands of diverse dining preferences.

Looking ahead, the future of commercial sandwich presses seems to be bright. With the rise of health-conscious consumers and the growing popularity of fast-casual dining, there is a clear demand for high-quality, quick-service options. The NSF Approved Sandwich Press is well-positioned to meet this demand with its innovative features and commitment to safety and quality.

The industry is also witnessing a trend towards customization and personalization. As customers seek unique dining experiences, the sandwich press allows for the creation of customized sandwiches, catering to specific dietary restrictions or personal tastes. This level of customization is not only attractive to customers but also a significant competitive advantage for businesses looking to stand out in a crowded market.

In conclusion, the NSF Approved Sandwich Press is more than just a kitchen appliance; it’s a strategic investment for any establishment that values efficiency, safety, and quality. Its versatility, ease of use, and adherence to stringent safety standards make it an essential tool for commercial kitchens. With its ability to meet the demands of modern diners and the expectations of environmentally conscious operators, the sandwich press is a must-have for any kitchen aiming to provide exceptional service and satisfy the palates of its customers.