Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary innovation meets technological advancement, the evolution of sandwich plates within kitchen appliances has sparked a revolution in home cooking. These humble yet sophisticated components play a pivotal role in shaping the way we prepare and enjoy our meals. As we delve into the intricacies of this sector, we uncover a landscape ripe with possibilities and groundbreaking concepts. Join us as we explore the dynamic world of sandwich plates and their promising future in the realm of kitchen appliances.

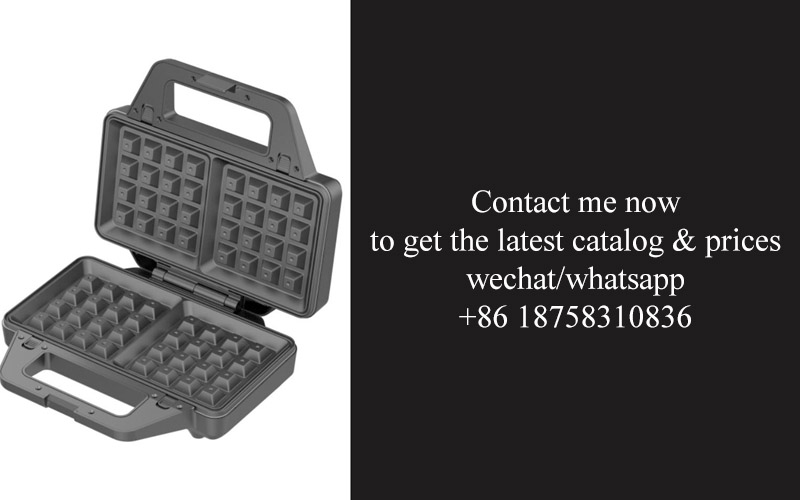

The evolution of sandwich plates in kitchen appliances is a testament to culinary innovation and the ever-growing demand for convenience. Once a simple staple of quick meals, the sandwich has now become a versatile canvas for culinary creativity. This transformation is evident in the evolution of sandwich plates, which have evolved from basic, utilitarian pieces to sophisticated, multifunctional tools that enhance the cooking experience.

Early sandwich plates were straightforward, often made of ceramic or glass, and their primary function was to hold the sandwich securely while it was being eaten. However, as the sandwich became more than just a meal, so too did the sandwich plate. The introduction of metal sandwich plates marked a significant shift, offering durability and a sleek aesthetic that complemented the growing popularity of gourmet sandwiches.

With the advent of integrated metal stamping technology, sandwich plates began to feature intricate designs and improved functionality. The ability to stamp metal with precision allowed for the creation of plates with unique patterns and contours that not only served the practical purpose of holding a sandwich but also added a visual element to the dining experience.

One of the most notable advancements in sandwich plate design is the integration of non-stick surfaces. This innovation has made it possible to cook directly on the plate, allowing for the creation of toasted sandwiches with minimal effort. The non-stick coating ensures that the sandwich stays intact while the outer layers are perfectly browned, a feature that has become a favorite among sandwich enthusiasts.

The rise of food blogs and social media platforms has also played a role in the evolution of sandwich plates. As home chefs share their recipes and cooking techniques, they often showcase their specialized equipment, including high-quality sandwich plates. This has led to a trend where sandwich plates are not just cooking tools but also status symbols, reflecting the cook’s dedication to quality and innovation.

As kitchen appliances have become more integrated into our daily lives, sandwich plates have followed suit. Modern sandwich plates are often part of a larger appliance suite that includes toasters, grills, and even ovens. These multi-functional units allow for the creation of not just traditional sandwiches, but also gourmet creations like panini, melts, and even breakfast sandwiches.

The integration of smart technology into sandwich plates is another exciting development. Some models now come with temperature controls, timers, and even Bluetooth connectivity, allowing users to monitor and adjust the cooking process remotely. This level of customization ensures that each sandwich is cooked to perfection, with the exact level of crispiness and warmth that the cook desires.

In terms of materials, sandwich plates have expanded beyond traditional metals like stainless steel to include materials like aluminum and even high-grade plastics. These materials offer different benefits, such as lightweight construction, heat resistance, and ease of cleaning, making them suitable for a wide range of cooking styles and preferences.

The evolution of sandwich plates has also been influenced by health and wellness trends. With an increasing focus on nutritious eating, sandwich plates that can be used for both cooking and serving have become popular. These plates often come with removable inserts or lids, allowing for easy storage and transport of sandwiches, salads, or other meal components.

Lastly, the sustainability movement has had an impact on sandwich plate design. Manufacturers are now exploring eco-friendly materials and sustainable production processes to reduce their environmental footprint. This has led to the creation of sandwich plates that are not only functional and stylish but also environmentally responsible.

In conclusion, the evolution of sandwich plates in kitchen appliances is a story of innovation, convenience, and personalization. From simple holders of food to sophisticated culinary tools, sandwich plates have come a long way, reflecting the changing landscape of food culture and the ever-growing desire for culinary excellence.

Integrated metal stamping is a sophisticated process that has revolutionized the production of various components, including those found in kitchen appliances. This method involves the use of dies and presses to shape metal sheets into intricate shapes, offering a high degree of precision and efficiency. Let’s delve into the intricacies of this process.

The process begins with the creation of a die, which is a tool that has the exact shape and dimensions of the final product. These dies are typically made from high-quality steel or other durable materials to withstand the immense pressure exerted during the stamping process. The design of the die is crucial, as it directly influences the quality and finish of the stamped parts.

Once the die is ready, the metal sheets are loaded into the press. These sheets are usually made from materials like stainless steel, aluminum, or brass, chosen for their durability and resistance to corrosion. The metal is cut into the desired shape and thickness before being fed into the press, where it will be transformed into the final component.

The stamping process itself is a high-speed operation. The press applies a significant amount of pressure to the metal sheet, causing it to conform to the shape of the die. This pressure can range from a few hundred tons to several thousand tons, depending on the size and complexity of the part being produced. The force is delivered quickly, which helps to minimize the risk of metal deformation and ensures that the stamped parts meet the required specifications.

One of the key advantages of integrated metal stamping is its ability to create intricate designs and features that would be difficult or impossible to achieve through other manufacturing methods. For example, the process can create fine details, such as threading, grooves, and embossed patterns, which are essential for the functionality and aesthetics of kitchen appliances.

Another important aspect of integrated metal stamping is the ability to produce parts with high tolerances. Tolerance refers to the amount of variation allowed in the dimensions of a part. With integrated metal stamping, manufacturers can achieve very tight tolerances, ensuring that the parts fit together perfectly and function as intended. This is particularly crucial in kitchen appliances, where the components must work seamlessly to provide a smooth and efficient cooking experience.

The efficiency of integrated metal stamping is also a significant factor in its popularity. The process allows for the production of large quantities of parts in a short amount of time, which can lead to significant cost savings. Additionally, the automation of the stamping process reduces the need for manual labor, further enhancing productivity and reducing the risk of human error.

One of the challenges of integrated metal stamping is the need for precise control over the stamping parameters. Factors such as the speed of the press, the temperature of the metal, and the lubrication used during the process can all impact the quality of the final product. As a result, manufacturers must carefully monitor and adjust these parameters to ensure consistent and reliable results.

In recent years, there has been a growing trend towards the use of advanced materials in kitchen appliances. Integrated metal stamping has adapted to this trend by enabling the production of parts made from materials like titanium and high-strength alloys. These materials offer enhanced durability and performance, making them ideal for high-end kitchen appliances.

The environmental impact of manufacturing processes is also a growing concern. Integrated metal stamping is inherently more sustainable than some other methods, as it requires less energy and produces fewer waste products. Additionally, the longevity of the stamped parts means that they are less likely to end up in landfills.

In conclusion, integrated metal stamping is a versatile and efficient process that plays a crucial role in the production of kitchen appliances. Its ability to create precise, intricate parts with high tolerances, combined with its cost-effectiveness and sustainability, makes it an essential component of modern manufacturing. As technology continues to evolve, we can expect to see further advancements in the capabilities of integrated metal stamping, leading to even more innovative and efficient kitchen appliances in the future.

The sandwich plate, a seemingly simple component, plays a pivotal role in the evolution of modern kitchen appliances. It’s not just a vessel for holding food; it’s a key element that enhances functionality, convenience, and, ultimately, the culinary experience.

As kitchen appliances have evolved, so too has the sandwich plate. Once a basic, flat metal surface, it has transformed into a sophisticated tool that can cater to a variety of culinary needs. From the classic, single-layer design to multi-tiered, adjustable plates, the sandwich plate has become a versatile accessory that can accommodate everything from single-serve meals to family-sized portions.

In the realm of modern kitchen appliances, sandwich plates are often integrated into toasters, sandwich makers, and other similar gadgets. These plates are designed to evenly distribute heat, ensuring that each layer of the sandwich is toasted to perfection. The precise contours of the plate help to maintain the integrity of the sandwich, preventing the bread from becoming too crispy or burning.

One of the standout features of the modern sandwich plate is its non-stick surface. This innovation not only makes cleaning easier but also ensures that the sandwich remains intact during the cooking process. The non-stick coating is often made from materials like Teflon, which can withstand high temperatures without releasing harmful chemicals.

In addition to toasters, sandwich plates are also a staple in sandwich makers. These appliances have become increasingly popular due to their ability to produce a variety of sandwich options with minimal effort. The sandwich plate in a sandwich maker is designed to fit snugly around the ingredients, ensuring that the heat is evenly distributed and that the sandwich is cooked to the desired level of crispness.

The adjustable nature of some sandwich plates is another feature that has made them indispensable in modern kitchen appliances. Users can often adjust the thickness of the sandwich by changing the position of the plate, which is particularly useful for those who prefer their sandwiches toasted to different levels or who are preparing sandwiches for individuals with varying dietary preferences.

In the realm of health and wellness, sandwich plates have also adapted to cater to specific needs. For example, there are models that come with removable inserts for healthier eating options, such as whole grain breads or gluten-free alternatives. These inserts not only provide a better grip on the bread but also help to maintain the sandwich’s shape during the cooking process.

Moreover, the sandwich plate has expanded beyond the confines of toasters and sandwich makers. It’s now a common component in countertop grills, panini presses, and even some oven-safe appliances. The versatility of the sandwich plate allows it to be used for a wide range of foods, from the traditional ham and cheese to gourmet creations with layers of vegetables, meats, and cheeses.

The design of the sandwich plate has also become more innovative. Some models now come with built-in features like adjustable temperature controls, allowing users to customize the cooking process to their liking. Others are equipped with features that can be used to monitor the sandwich’s progress, ensuring that it’s cooked to the perfect level.

In the world of convenience, the sandwich plate is a game-changer. It allows for quick and easy preparation of a meal that is both satisfying and nutritious. In today’s fast-paced lifestyle, the ability to throw together a sandwich with the touch of a button is a luxury that many people appreciate.

The sandwich plate’s role in modern kitchen appliances is not just about convenience; it’s about enhancing the quality of life. By providing a tool that can be used for a variety of recipes and dietary needs, the sandwich plate has become an integral part of how we approach meal preparation in the modern kitchen. Its ability to adapt to new technologies and consumer demands makes it a symbol of how kitchen appliances continue to evolve to meet our needs.

The Integrated Metal Stamping Process for Sandwich Plates

Metal stamping is a fundamental manufacturing technique that involves the shaping of sheet metal into various forms, including those used in kitchen appliances like sandwich plates. This process is not only precise but also efficient, allowing for the creation of intricate and durable components. Let’s delve into the intricate steps involved in the production of sandwich plates through integrated metal stamping.

The journey begins with a detailed design phase. Engineers and designers collaborate to create a blueprint for the sandwich plate, ensuring it meets the required specifications and integrates seamlessly with other kitchen appliances. This design must consider factors such as the thickness of the metal, the shape and size of the plate, and the overall functionality it needs to serve.

Once the design is finalized, the choice of material is crucial. For sandwich plates, materials like stainless steel are often preferred due to their durability and resistance to corrosion. The chosen material is then rolled into sheets of the desired thickness, which will serve as the starting point for the stamping process.

The next step involves the creation of the punches and dies. These are custom tools that will be used to shape the metal. The punches are the tools that do the actual piercing, cutting, and forming, while the dies are the negative impressions that the metal will conform to. Each punch and die set is meticulously crafted to match the design of the sandwich plate.

The blanking process is where the sheet metal is transformed into individual blanks, or shapes, that will eventually become the sandwich plates. This is done by placing the sheet metal between the punch and the die, applying pressure, and then removing the excess material. The result is a blank that closely matches the final shape of the plate.

After blanking, the metal is ready for forming. This step involves shaping the blank into the desired profile using presses. The presses exert force on the blank, causing it to bend and take on the contours of the die. Careful control of pressure and speed is necessary to ensure the metal does not crack or tear.

If the sandwich plate requires any holes for screws or other fasteners, this is the stage where they are created. Specialized punches are used to pierce the metal at the precise locations. This process is repeated for each hole, and the resulting holes must be aligned perfectly with the overall design of the plate.

Once the metal has been shaped into the sandwich plate, various finishing operations are performed. This can include deburring to remove sharp edges, surface finishing to improve the appearance and durability, and heat-treating to increase strength and resilience. Each operation is carefully controlled to meet the desired quality standards.

After the metal stamping and finishing processes, the sandwich plates are assembled with any additional components, such as mounting brackets or non-slip pads. The assembled plates then undergo rigorous quality control checks to ensure they meet the required specifications and are free from defects.

Once the sandwich plates have passed quality control, they are packaged in protective materials to prevent damage during transportation. The packaged products are then distributed to manufacturers of kitchen appliances, ready to be integrated into the final product line.

Throughout the entire process, there is a focus on continuous improvement. Manufacturers constantly seek ways to optimize the metal stamping process, reduce waste, and improve efficiency. This includes investing in new equipment, refining techniques, and staying abreast of the latest industry developments.

The integrated metal stamping process for sandwich plates is a testament to the precision and innovation that goes into the manufacturing of kitchen appliances. Each step is crucial to ensuring that the final product is not only functional but also aesthetically pleasing and durable.

In the realm of manufacturing, integrated metal stamping stands out as a technique that offers a multitude of benefits, making it a preferred choice for producing sandwich plates and various other components. Here’s an exploration of some of the key advantages this process brings to the table.

Precision and ConsistencyEvery sandwich plate, regardless of its size or complexity, demands precision and consistency. Integrated metal stamping ensures that each piece is uniform, with tight tolerances that meet the highest standards of quality. The process involves the use of dies that are meticulously designed to shape the metal precisely, resulting in components that fit seamlessly together.

Cost-EffectivenessOne of the most significant benefits of integrated metal stamping is its cost-effectiveness. The process is highly automated, which reduces labor costs and increases production speed. Additionally, since the dies are reusable, the cost per unit decreases over time. This efficiency makes it an economical choice for high-volume production, which is often the case with sandwich plates.

DurabilitySandwich plates are designed to withstand the rigors of kitchen use, from hot to cold temperatures and frequent cleaning. Integrated metal stamping contributes to the durability of these plates by creating a strong, robust material that can endure these conditions. The metal’s inherent strength is enhanced by the stamping process, which compresses and forms the material into a uniform thickness, reducing the likelihood of bending or warping.

VersatilityThe process of integrated metal stamping is incredibly versatile, allowing for the creation of a wide range of sandwich plate designs. Whether it’s a simple flat plate or a complex multi-layered design, the stamping process can accommodate various shapes and sizes. This flexibility means that manufacturers can cater to different market demands and customer preferences without compromising on quality.

Efficient ProductionEfficiency is a cornerstone of the integrated metal stamping process. The ability to produce a large number of parts in a short amount of time is invaluable, especially in the kitchen appliance industry where time-to-market is crucial. The continuous flow of materials through the stamping press means that production can run smoothly and consistently, minimizing downtime and increasing output.

Reduced WasteWaste is a concern in any manufacturing process, but integrated metal stamping minimizes it significantly. The precision of the stamping process ensures that materials are used efficiently, with minimal scrap. This not only reduces the environmental impact but also saves costs associated with waste disposal and the need for additional materials.

Enhanced Design FeaturesIntegrated metal stamping allows for the incorporation of design features that might be challenging to achieve through other manufacturing methods. For example, the process can create intricate patterns, embossed logos, or even integrated features like handles or drainage systems in sandwich plates. This design freedom can lead to innovative and aesthetically pleasing products that stand out in the market.

Customization and ScalabilityManufacturers can easily customize sandwich plates to meet specific requirements. Whether it’s a unique shape, a specialized finish, or a specific thickness, the stamping process can be adjusted to accommodate these needs. This scalability is particularly beneficial as companies grow and their product lines expand.

Quality ControlMaintaining quality is paramount in the kitchen appliance industry. Integrated metal stamping facilitates quality control through its consistent and repeatable process. Each step, from material selection to the final product, can be monitored and adjusted to ensure that the final sandwich plate meets the required standards.

In conclusion, the benefits of integrated metal stamping for sandwich plates are clear. From precision and cost-effectiveness to durability and design flexibility, this manufacturing process offers a comprehensive solution that meets the demands of the modern kitchen appliance market. As technology continues to advance, the advantages of integrated metal stamping are likely to expand, further solidifying its position as a key player in the production of high-quality sandwich plates.

In the ever-evolving landscape of the kitchen appliances industry, staying abreast of industry insights and market trends is crucial for businesses looking to innovate and thrive. Here’s a glimpse into the current state of the market:

The rise of smart kitchen technology has been a significant trend, with consumers increasingly seeking appliances that offer convenience, efficiency, and connectivity. Smart ovens, refrigerators with internet capabilities, and even smart cooktops are becoming more common in modern homes.

Customization is another key trend, as consumers look for appliances that cater to their specific needs and preferences. From different sizes and styles to specialized features, the market is seeing a shift towards personalized kitchen solutions.

Energy efficiency remains a top priority, with manufacturers focusing on developing appliances that consume less energy while still delivering high performance. This not only benefits the environment but also appeals to environmentally conscious consumers who are willing to invest in sustainable products.

Sustainability is not just about energy efficiency; it’s also about the materials used in manufacturing. There’s a growing demand for appliances made from recycled materials, and companies that can demonstrate their commitment to sustainability often gain a competitive edge.

The integration of health and wellness features into kitchen appliances is on the rise. For example, ovens with steam cooking capabilities or refrigerators that offer air purification systems are becoming more popular as consumers seek healthier cooking and storage options.

E-commerce has transformed the way consumers purchase kitchen appliances. Online marketplaces have made it easier for customers to compare products, read reviews, and make purchases from the comfort of their homes. This shift has also led to increased competition and the need for businesses to optimize their online presence.

Globalization has expanded the market for kitchen appliances, with emerging markets like China, India, and Brazil presenting significant growth opportunities. However, navigating these markets requires a deep understanding of local preferences and regulations.

Regulatory changes can have a profound impact on the industry. For instance, new energy standards or safety regulations can influence product design and pricing. Staying informed about these changes is essential for compliance and maintaining a competitive edge.

The trend towards compact living spaces has influenced the design of kitchen appliances. Smaller, space-saving models are in demand, as consumers look for ways to make the most of limited kitchen areas.

Collaborations between appliance manufacturers and technology companies are becoming more common. These partnerships often lead to the development of innovative products that combine the latest technology with kitchen appliances.

The rise of social media and influencer marketing has changed how kitchen appliances are promoted. Brands are now leveraging these platforms to reach consumers and showcase their products in a more engaging and personal way.

Lastly, the importance of user experience cannot be overstated. Consumers are not just looking for functional appliances; they want products that are intuitive, easy to use, and add value to their daily lives. This focus on user experience is shaping the future of kitchen appliances.

In the ever-evolving world of kitchen appliances, the sandwich plate has become a staple in modern cooking. This simple yet innovative component has transformed the way we prepare and enjoy sandwiches at home. Let’s delve into some unique ideas that are driving the innovation in sandwich plate design.

Multi-FunctionalityOne of the key trends in sandwich plate innovation is the incorporation of multi-functionality. Imagine a sandwich plate that not only serves as a cooking surface but also doubles as a cutting board or a serving tray. This dual-purpose design would save space and streamline kitchen tasks.

Temperature ControlA unique feature that has been gaining traction is temperature control in sandwich plates. With the ability to maintain a consistent heat or cold temperature, these plates could cater to a variety of sandwich recipes, from toasted to cold cuts, and even frozen desserts.

Smart Technology IntegrationThe integration of smart technology into sandwich plates is another innovative direction. Imagine a plate that connects to your smartphone, allowing you to monitor the cooking progress, set timers, and even receive alerts when your sandwich is ready to be served. This would be particularly useful for those who are visually impaired or have limited mobility.

Customizable Surface PatternsOne way to add a personal touch to sandwich plates is through customizable surface patterns. Users could choose from a range of designs or even upload their own images to be etched or printed onto the plate. This not only makes the plate a functional tool but also a statement piece for the kitchen.

Eco-Friendly MaterialsSustainability is a major concern for many consumers, and sandwich plates are no exception. Innovators are exploring eco-friendly materials such as recycled stainless steel or bamboo, which are not only better for the environment but also offer unique aesthetic qualities.

Built-In SensorsIn the realm of smart kitchen appliances, built-in sensors in sandwich plates can revolutionize cooking. These sensors could detect the moisture content of the ingredients, ensuring that the sandwich is cooked to perfection every time. It could also alert users to the optimal time to add condiments or toppings for the best flavor.

Modular DesignModular sandwich plates can be assembled in various configurations, allowing users to create different shapes and sizes of sandwiches. This not only adds variety to the cooking experience but also encourages culinary creativity.

Interactive Learning FeaturesFor those looking to improve their sandwich-making skills, interactive learning features on sandwich plates could be a game-changer. A built-in guide could provide tips and tricks, step-by-step instructions, and even a recipe database, making it easier for beginners to master the art of sandwich preparation.

Enhanced Safety FeaturesSafety is always a priority, and sandwich plates can incorporate additional features to prevent accidents. For example, a non-slip base could keep the plate stable on uneven surfaces, and heat-resistant handles could prevent burns when moving the plate in and out of the oven.

Versatile Attachment OptionsFinally, sandwich plates could be designed with attachment options for various accessories, such as built-in toasters, sandwich presses, or cheese graters. This would allow for a seamless cooking experience where all the necessary tools are readily available in one unit.

By embracing these unique ideas, the sandwich plate is poised to become an integral part of the modern kitchen, offering not just a cooking tool but an experience that is tailored to the needs and desires of the contemporary home cook.

In the ever-evolving landscape of kitchen appliances, the sandwich plate market has seen a surge in interest and innovation. Analyzing the data reveals several key trends and insights that are shaping the industry.

Consumer Preferences ShiftThe data indicates a notable shift in consumer preferences, with a growing number of consumers looking for convenience and efficiency in their kitchen appliances. This trend is reflected in the popularity of sandwich plates, which are designed to streamline the process of making sandwiches at home.

Market SegmentationMarket segmentation plays a crucial role in understanding the sandwich plate market. Data shows that there are distinct segments, including single-use sandwich makers, countertop models, and high-end appliances with advanced features. Each segment caters to different consumer needs and budgets.

Growth in Smart FeaturesA significant trend in the sandwich plate market is the integration of smart features. Data suggests that consumers are increasingly interested in appliances that offer programmability, connectivity, and the ability to adjust settings remotely. Smart sandwich plates are becoming more common, driven by the demand for convenience and customization.

Regional VariationsRegional variations are evident in the sandwich plate market. In some areas, there’s a preference for compact, portable sandwich makers, while in others, there’s a higher demand for countertop models that offer versatility and the ability to make a variety of sandwich types. Data analysis helps manufacturers tailor their products to meet these regional preferences.

Product Development TrendsThe data reveals that product development in the sandwich plate market is focused on several key areas. These include improved materials for durability and ease of cleaning, enhanced heating elements for even cooking, and innovative designs that can accommodate a wider range of sandwich fillings. Manufacturers are also looking to incorporate features that reduce energy consumption and minimize waste.

Marketing StrategiesMarketing strategies in the sandwich plate market are becoming more targeted and data-driven. Companies are using consumer insights to create campaigns that resonate with their target audience. Data analytics helps in identifying the most effective marketing channels and messaging to boost sales.

Environmental ConcernsAn increasing number of consumers are considering the environmental impact of their purchases. Data shows that there’s a growing demand for sandwich plates made from sustainable materials and designed for longevity. This trend is prompting manufacturers to explore eco-friendly options and to communicate their commitment to sustainability in their marketing efforts.

E-commerce ImpactThe rise of e-commerce has had a significant impact on the sandwich plate market. Data indicates that a large portion of sales are now made online, with consumers gravitating towards the convenience of shopping from home. This shift has led to a need for manufacturers to optimize their online presence and ensure that their products are easily accessible to a global audience.

Regulatory ComplianceRegulatory compliance is a critical factor in the sandwich plate market. Data analysis helps manufacturers stay informed about the latest safety standards and certifications required in different regions. Ensuring compliance not only protects consumers but also helps maintain a brand’s reputation.

Competitive LandscapeThe competitive landscape in the sandwich plate market is dynamic. Data reveals that there are numerous players, each with their own unique selling points. Understanding the competitive landscape allows manufacturers to identify gaps in the market and develop strategies to differentiate their products.

Future OutlookLooking ahead, the sandwich plate market is expected to continue growing, driven by consumer demand for convenience, innovation, and sustainability. Data-driven analysis will be key to predicting future trends and developing products that meet the evolving needs of consumers.

In the realm of integrated metal stamping, there are numerous success stories that highlight the precision and efficiency of this manufacturing process. Let’s delve into a few case studies that showcase the successful implementations of integrated metal stamping in various industries.

A culinary innovation emerged when a renowned kitchen appliance manufacturer decided to incorporate a new, sleek design for their sandwich plates. The plates were crafted using integrated metal stamping, which allowed for intricate details and a uniform finish. This not only enhanced the aesthetic appeal of the product but also improved its functionality.

The automotive industry saw a transformation with the use of integrated metal stamping in the production of lightweight and durable components. A leading car manufacturer turned to this technology to create custom brackets and clips for their vehicles. The stamps were designed to create intricate patterns and tight tolerances, ensuring that the parts fit perfectly and contributed to the overall performance of the car.

A global electronics giant faced the challenge of reducing the size and weight of their electronic devices while maintaining structural integrity. They turned to integrated metal stamping to produce thin, precise metal parts for their smartphones and laptops. The process allowed for complex geometries and tight tolerances, resulting in a product that was both efficient and sleek.

The aerospace sector required lightweight components that could withstand extreme temperatures and harsh conditions. Integrated metal stamping was the answer for a major aircraft manufacturer, who used it to create intricate parts for their engines and airframes. The process allowed for the production of complex shapes that were both lightweight and strong, significantly enhancing the aircraft’s performance and fuel efficiency.

A home appliance brand aimed to create a unique and innovative toaster that could cater to a wide range of sandwich preferences. They turned to integrated metal stamping to produce a customizable sandwich plate that could be easily swapped out to accommodate different bread sizes and sandwich fillings. The process enabled the creation of a versatile and attractive product that resonated with consumers.

A furniture manufacturer sought to design a modern and sleek coffee table that would complement contemporary living spaces. They chose integrated metal stamping to create the table’s frame, which featured a unique, curved design. The process allowed for the creation of intricate shapes and a seamless finish, resulting in a product that was both visually stunning and structurally sound.

A sports equipment company wanted to improve the performance of their tennis rackets by incorporating a lightweight, yet strong frame. Integrated metal stamping was the solution, enabling the production of a frame that was both lightweight and able to withstand the stresses of the game. The stamps were designed to create precise angles and reinforced areas, ensuring that the racket was durable and responsive.

An industrial equipment manufacturer faced the challenge of creating a custom part for a specialized machine that required high precision and durability. They turned to integrated metal stamping, which allowed them to produce the part with tight tolerances and a high degree of consistency. The success of this implementation led to further collaborations with the manufacturer, expanding their use of the technology across multiple projects.

These case studies demonstrate the versatility and effectiveness of integrated metal stamping in a wide range of industries. From consumer products to industrial equipment, the technology continues to drive innovation and improve the quality of goods we use every day.

In the realm of kitchen appliances, sandwich plates have emerged as a pivotal component, enhancing the convenience and quality of home cooking. As we look to the future, several trends and innovations are poised to shape the evolution of sandwich plates and their integration into kitchen appliances.

Innovation often stems from the need to simplify tasks and streamline the cooking process. With this in mind, one can envision a future where sandwich plates are not just a tool for cooking but an integral part of a smart kitchen ecosystem. Imagine a sandwich plate that not only prepares your sandwich but also connects to your smartphone to provide nutritional information or recipe suggestions based on your dietary preferences.

The integration of advanced materials is another area ripe for innovation. For instance, sandwich plates made with conductive materials could offer the ability to heat food more evenly and precisely, reducing the risk of undercooked or overcooked sandwiches. The use of materials that are resistant to bacteria growth could also contribute to a more hygienic cooking environment.

Smart sensors within the sandwich plates could revolutionize the cooking experience. These sensors could monitor the temperature and humidity, adjusting the cooking cycle to ensure the perfect texture and flavor every time. Users could set their preferred cooking profile, and the sandwich plate would learn from these preferences, becoming more intuitive over time.

Design-wise, sandwich plates could evolve to be more compact and modular, allowing them to fit seamlessly into various kitchen layouts. This would be particularly beneficial in small apartments or homes where space is at a premium. The ability to customize the plate to fit specific needs, such as a larger baking surface for larger sandwiches or a flat top for cooking burgers, could also become a standard feature.

Energy efficiency is a growing concern, and future sandwich plates might incorporate energy-saving technologies. Solar-powered sandwich plates, for example, could harness ambient light to maintain a consistent cooking temperature, reducing the need for conventional electrical power.

The rise of eco-friendly materials is also shaping the future of sandwich plates. As consumers become more environmentally conscious, sandwich plates made from recycled or biodegradable materials could gain popularity. This not only aligns with sustainable practices but also appeals to those who prioritize the health of the planet.

Collaboration between appliance manufacturers and food tech startups could lead to the development of sandwich plates that offer a unique culinary experience. Imagine a sandwich plate that could infuse flavors or create textures not possible with traditional cooking methods. The potential for such innovation is vast, and it could open up new categories of food preparation within the kitchen.

In the realm of connectivity, sandwich plates could be part of a larger network of kitchen appliances that communicate with each other. This smart kitchen network could optimize energy use, manage inventory, and even suggest meal prep times based on the user’s schedule.

The future of sandwich plates is not just about cooking; it’s about enhancing the overall kitchen experience. As technology advances, we can expect sandwich plates to become more intuitive, efficient, and adaptable to the diverse needs of modern consumers. The possibilities are as limitless as the flavors of a sandwich, and the future holds an exciting array of possibilities for this humble yet essential kitchen tool.