Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In recent years, the sandwich press has quietly become a staple in many kitchens around the world. This unassuming kitchen gadget has found its way into the hearts of sandwich enthusiasts and culinary creatives alike, offering a simple yet effective solution for crafting the perfect pressed sandwich. With a rise in health-conscious eating and a growing demand for convenience, the market for heavy-duty sandwich presses has seen a significant uptick. In this exploration, we delve into the innovative designs and functionalities that have shaped the industry, the evolving market trends and consumer preferences, and the challenges and opportunities that lie ahead. Through case studies of successful heavy-duty sandwich press manufacturers, we aim to provide a comprehensive look at the state of the industry and the future of sandwich press production.

The heavy duty sandwich press market has seen a surge in popularity, becoming a staple in many modern kitchens across the globe. These robust appliances are not just for making the classic grilled cheese; they’ve evolved into versatile tools for crafting a wide array of culinary delights. From gourmet melts to artistic paninis, the demand for high-quality, durable sandwich presses has never been higher.

In recent years, the market has expanded significantly, with a growing number of consumers seeking out these versatile cooking devices. The convenience of making a delicious sandwich at home, without the need for a commercial grade oven or grill, has made the heavy duty sandwich press an appealing option for both busy professionals and casual home cooks.

These sandwich presses are designed with a focus on durability and performance. They are built to withstand constant use and the rigors of high heat, ensuring that every sandwich is cooked to perfection. The market is flooded with a variety of models, each offering unique features and benefits that cater to different consumer needs.

One of the standout aspects of the heavy duty sandwich press market is the innovation in design. Manufacturers are pushing the boundaries to create presses that not only deliver great tasting sandwiches but also offer a seamless cooking experience. The presses come with non-stick surfaces, adjustable heat settings, and even some with locking mechanisms for easy handling and storage.

The market has also seen a shift towards eco-friendly and sustainable materials. Consumers are increasingly conscious of the environmental impact of their purchases, and sandwich press manufacturers are responding by offering presses made from recycled materials or those that are designed for longevity, reducing the need for frequent replacements.

Another important factor driving the heavy duty sandwich press market is the growing interest in gourmet and artisanal cooking. As home chefs experiment with new ingredients and techniques, the need for a reliable tool that can handle various cooking methods, from the simple to the complex, has become a priority.

The market is segmented into several categories, each targeting a different consumer demographic. There are compact models perfect for small kitchens or apartments, as well as larger, more industrial-sized presses suitable for restaurants and commercial settings. The variety in sizes and capacities allows for customization to fit any space and budget.

As the market continues to grow, so does the competition. Brands are vying for market share by emphasizing the quality of their products, offering competitive pricing, and providing exceptional customer service. This competition has also led to a wealth of resources and support for consumers, including detailed product guides, recipe ideas, and even online communities where users can share their experiences and tips.

The heavy duty sandwich press market is not without its challenges. One of the biggest hurdles is the need for consistent quality control. With the varying demands of consumers and the complexities of manufacturing, ensuring that every press meets the high standards set by the brand can be a daunting task. However, this challenge has also spurred innovation in production processes and quality assurance methods.

Lastly, the market is poised for continued growth as technology advances. Smart features, such as digital displays and programmable settings, are becoming more common, making sandwich presses even more user-friendly. The integration of these features is expected to further enhance the appeal of heavy duty sandwich presses to a broader audience.

In summary, the heavy duty sandwich press market is a dynamic and evolving sector that reflects the changing tastes and preferences of consumers. With a focus on quality, innovation, and sustainability, this market is likely to see even more exciting developments in the years to come.

The surge in popularity of sandwich presses in Western markets has been nothing short of remarkable. With the rise of the fast-paced lifestyle, convenience has become a top priority for many consumers. Sandwich presses have capitalized on this trend by offering a quick and easy way to prepare delicious, homemade sandwiches without the need for a full kitchen setup.

Gone are the days when a sandwich was simply a slice of bread with a filling. Today, the sandwich has evolved into a culinary masterpiece, with a myriad of ingredients and flavors to choose from. This has led to a significant increase in the demand for high-quality sandwich presses that can handle the pressure of creating these sophisticated sandwiches.

One of the key factors driving the growth of the sandwich press market in Western countries is the rise of health consciousness among consumers. With the growing awareness of the benefits of whole grains, lean proteins, and fresh vegetables, people are seeking healthier alternatives to fast food. Sandwich presses provide a perfect solution, allowing individuals to customize their sandwiches with nutritious ingredients, all while enjoying the convenience of a quick meal.

The versatility of sandwich presses has also played a crucial role in their popularity. These appliances are not limited to just sandwiches; they can be used to create a variety of other dishes, such as paninis, wraps, and even grilled cheese. This adaptability has made sandwich presses a must-have kitchen gadget for many households, as they can cater to different tastes and preferences in a single device.

The convenience factor is further enhanced by the compact and user-friendly design of modern sandwich presses. They are designed to fit easily on kitchen countertops, saving valuable space. The intuitive controls and non-stick surfaces make them simple to use, even for those who are not as confident in the kitchen. This ease of use has made sandwich presses a staple in many homes, regardless of the skill level of the cook.

Another contributing factor to the rise of sandwich presses is the influence of social media and food blogs. With the proliferation of online content, people are constantly seeking inspiration for their meals. Sandwich presses have been featured in countless recipes and cooking tutorials, showcasing their versatility and ease of use. This has sparked a wave of enthusiasm for the appliance, as more and more people discover the joy of making their own gourmet sandwiches at home.

Moreover, the sandwich press market has seen a surge in innovation, with manufacturers constantly introducing new features and designs. From adjustable pressure settings to built-in timers and temperature controls, these appliances are becoming increasingly sophisticated. This innovation has not only improved the quality of the final product but has also expanded the potential uses of sandwich presses, making them a sought-after item in the kitchen.

In recent years, there has also been a growing interest in home cooking and DIY projects. As people seek to reconnect with their food and cooking traditions, sandwich presses have become a symbol of this movement. They offer a way to create unique and personalized meals, fostering a sense of accomplishment and satisfaction.

The environmental movement has also had a significant impact on the sandwich press market. With more consumers becoming environmentally conscious, there is a growing preference for appliances that are energy-efficient and sustainable. Sandwich presses, which require minimal energy to operate, have become a more eco-friendly choice for those looking to reduce their carbon footprint.

In conclusion, the rise of sandwich presses in Western markets can be attributed to a combination of factors, including the demand for convenience, health consciousness, versatility, and innovation. As these appliances continue to evolve and adapt to the changing needs of consumers, their popularity is expected to soar even further, solidifying their place as a staple in modern kitchens.

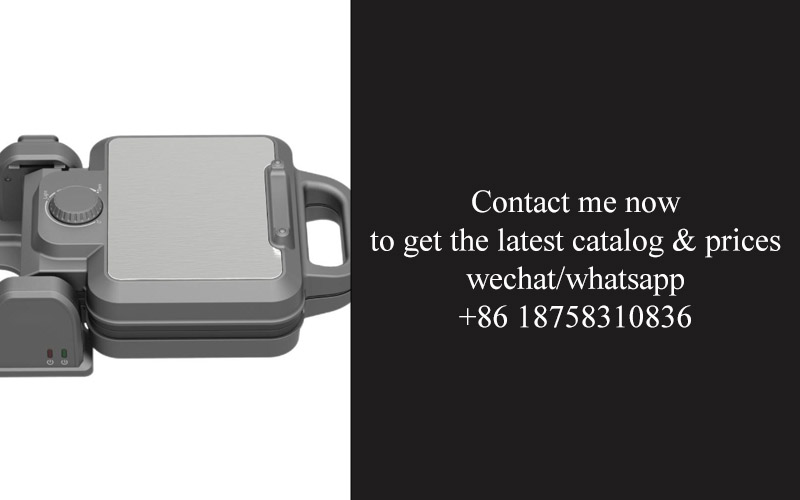

In the bustling world of kitchen appliances, the heavy-duty sandwich press factory stands as a cornerstone of innovation and functionality. These factories are not just about producing sandwiches; they are crafting tools that cater to the culinary passions of individuals and the demands of commercial kitchens alike. Here are some key features that define these factories:

The robust design of heavy-duty sandwich presses is a testament to their durability. These presses are built to withstand the rigors of constant use, ensuring that they remain a reliable companion in any setting. The frames are often made from high-quality stainless steel, which not only adds to the longevity of the press but also contributes to its sleek and modern aesthetic.

Precision engineering is at the heart of a heavy-duty sandwich press factory. The components are meticulously crafted to fit together seamlessly, ensuring that every press operates with precision. From the heat distribution system to the pressure plates, each part is designed to deliver consistent results, whether you’re pressing a classic grilled cheese or a gourmet panini.

Heat control is a crucial feature in any sandwich press. In a heavy-duty factory, this is achieved through advanced thermostats and heat sensors that maintain a stable and even temperature throughout the pressing process. This not only guarantees the perfect level of doneness but also prevents burning, which is a common issue with cheaper models.

The ability to adjust the pressure is a hallmark of high-quality sandwich presses. In a factory setting, this feature is often built into the design, allowing users to control the amount of pressure applied to the sandwich. This flexibility is essential for achieving different textures and levels of crispiness, from a soft, melt-in-the-mouth sandwich to a well-seared, crusty exterior.

Safety features are paramount in a heavy-duty sandwich press factory. These presses are equipped with safety locks that prevent accidental operation, ensuring that both the user and the appliance are protected. Additionally, many models come with non-slip bases and cool-touch handles, reducing the risk of accidents and burns.

Customization is a key aspect of the heavy-duty sandwich press market. Factories understand that different customers have different needs, so they offer a range of options to suit various requirements. This includes different sizes of presses, various heating elements for different types of bread, and even the ability to add additional features like grilling plates or toasting capabilities.

Quality control is a non-negotiable in a heavy-duty sandwich press factory. Every press that leaves the factory undergoes rigorous testing to ensure it meets the highest standards of performance and safety. This includes testing for heat distribution, pressure consistency, and overall durability, guaranteeing that customers receive a product that is built to last.

Innovation is a driving force in the heavy-duty sandwich press industry. Factories are constantly exploring new materials, technologies, and designs to improve their products. This might involve integrating smart technology for temperature control, using eco-friendly materials, or developing presses that are more user-friendly and efficient.

The manufacturing process itself is a blend of art and science. A heavy-duty sandwich press factory is equipped with state-of-the-art machinery that can handle large-scale production while maintaining the precision and quality of each unit. This includes CNC machines for precision cutting, automated assembly lines, and quality assurance checks at every stage.

Lastly, sustainability is a growing concern in the kitchen appliance industry. Heavy-duty sandwich press factories are increasingly adopting green practices, from sourcing recycled materials to reducing energy consumption during production. This not only benefits the environment but also appeals to consumers who are conscious of their ecological footprint.

In summary, the key features of a heavy-duty sandwich press factory encompass a robust design, precision engineering, heat control, pressure adjustment, safety features, customization, quality control, innovation, advanced manufacturing processes, and sustainability. These elements come together to create a product that is not just a kitchen appliance but a symbol of craftsmanship and reliability.

In today’s fast-paced world, the demand for convenience and innovation has driven the kitchen appliances industry to new heights. This is especially true for heavy-duty sandwich presses, which have seen a surge in popularity in Western markets. These presses aren’t just your average cooking gadgets; they are engineering marvels that blend style, functionality, and culinary precision. Let’s dive into some of the innovative designs and functionalities that set these sandwich presses apart.

One of the standout features of modern heavy-duty sandwich presses is their sleek and contemporary design. With sleek stainless steel exteriors and minimalist lines, these presses not only serve a practical purpose but also add a touch of modern elegance to any kitchen. The design often incorporates ergonomics, making it easier to handle and operate, which is a crucial factor for users looking for a seamless cooking experience.

Durability is a hallmark of heavy-duty sandwich presses. These presses are built to withstand frequent use and heavy loads. They typically feature sturdy construction with high-quality materials, ensuring that they can maintain their shape and integrity over time. This durability is achieved through reinforced frames and solid hinges, which prevent bending or warping, even when pressing dense, filling-rich sandwiches.

The heating elements within these sandwich presses are not just any old heating plates. Advanced heating technology, often including thermostats and temperature controls, ensures consistent and even heat distribution across the press. This is crucial for achieving the perfect golden-brown crust on the bread without overcooking the filling. The precise temperature control also means that users can tailor the cooking to their preference, whether they like their sandwiches toasted or crispy.

Functionality isn’t just about heat distribution; it’s also about ease of use. Many heavy-duty sandwich presses come with non-stick surfaces, which make cleanup a breeze. The removable plates are also designed for quick and thorough cleaning, so there’s no need to struggle with stubborn food particles or leftover grease. Additionally, features like adjustable pressure settings allow users to control the degree of compression, ensuring that sandwiches are pressed to perfection every time.

One of the latest innovations in sandwich press design is the inclusion of multi-functionality. Modern presses are no longer just for sandwiches. They can handle everything from panini to grilled cheese and even tofu burgers. Some models come with interchangeable plates that allow for different types of cooking, from searing to grilling, which makes them a versatile addition to any kitchen.

The technology within these sandwich presses has also advanced significantly. Many now feature digital displays, allowing users to set and monitor the cooking temperature and time. This not only provides a visual cue for when the sandwich is ready but also serves as a safety feature, preventing overcooking and potential fires.

Safety is a paramount concern, and heavy-duty sandwich presses are designed with multiple safety features. Locking mechanisms prevent the press from accidentally closing during operation, and heat-resistant handles ensure that users can safely remove the sandwich without the risk of burns. Some models also have safety interlocks that disable the press if it is opened while in use.

In terms of aesthetics, designers have gone to great lengths to create sandwich presses that not only perform well but also look fantastic. The surfaces are often treated to be fingerprint-resistant, and some presses even offer customizable options, allowing users to personalize their appliance with a wide range of colors and designs.

The functionality doesn’t end with the cooking surface. Many heavy-duty sandwich presses come with features like a drip tray to catch any excess fat or liquid, and a non-slip base to prevent the press from sliding around the countertop during use.

In conclusion, the innovative designs and functionalities of heavy-duty sandwich presses have made them a must-have appliance for sandwich enthusiasts and busy households alike. From their sleek, modern designs to their advanced technology and safety features, these presses are a testament to the evolution of kitchen appliances and the ever-growing demand for convenience and quality in our everyday lives.

In recent years, the market for kitchen appliances has seen a surge in interest for innovative and functional designs, especially in the realm of sandwich presses. This demand has been driven by changing consumer preferences, the rise of health-conscious eating, and the growing popularity of homemade meals. Let’s delve into the latest market trends and the preferences that are shaping the sandwich press industry.

The shift towards healthier eating habits has been a significant factor influencing the design of sandwich presses. Consumers are increasingly looking for appliances that not only make delicious sandwiches but also offer features that cater to their dietary needs. For instance, some presses are now equipped with adjustable heating elements, allowing users to control the level of crispiness and toasting of their bread, thus accommodating both those who prefer a softer texture and those who enjoy a perfectly golden brown crust.

Modern sandwich presses are not just for toasting; they have evolved to include a variety of functionalities that cater to a broader range of culinary desires. Many models now come with non-stick surfaces that ensure even heating and easy release of sandwiches, minimizing the need for added oils or fats. This feature is particularly appealing to those following low-fat or vegan diets.

The convenience factor is another key driver in the market. With busy lifestyles, consumers are seeking appliances that save time and effort in the kitchen. Sandwich presses with rapid heating capabilities and quick release mechanisms are becoming more popular, as they allow users to prepare a sandwich in just a few minutes. Some models even come with timers, so users can set their preferred cooking time, ensuring the perfect sandwich every time.

Functionality also extends to the design of the presses themselves. New models are sleeker and more compact, making them a perfect fit for modern kitchens that value space efficiency. The handles and hinges are often designed with ergonomics in mind, providing a comfortable grip and reducing the risk of burns during use.

Another trend that’s gaining traction is the inclusion of additional features such as integrated grilling surfaces or panini presses, which allow users to create a variety of meals beyond sandwiches. These multifunctional appliances are appealing to those who enjoy experimenting with different recipes and want a versatile tool in their kitchen arsenal.

In terms of materials, there’s a move towards sustainability and durability. High-quality stainless steel and cast aluminum are popular choices for their ability to withstand high temperatures and maintain their appearance over time. Some manufacturers are also exploring eco-friendly materials and sustainable practices, which resonate with environmentally conscious consumers.

Color and aesthetics are also playing a role in consumer preferences. While traditional sandwich presses were often found in basic black or silver, there’s now a wider range of colors and finishes available. Consumers are more likely to choose a sandwich press that complements their kitchen’s decor, reflecting their personal style.

As for brand preferences, the market is seeing a rise in the importance of brand reputation and customer reviews. Consumers are more likely to trust brands that have a history of producing reliable and durable appliances. The power of social media and online communities has also made word-of-mouth a significant factor in purchasing decisions.

The integration of technology is another area where market trends are heading. Smart kitchen appliances that can be controlled via smartphone apps are becoming more common, allowing users to program their sandwich presses for specific times or temperatures, even when they’re not at home.

Lastly, the rise of health and wellness culture has spurred a demand for sandwich presses that can handle a variety of bread types, including gluten-free and whole grain options. This means that the design and functionality of these appliances must be versatile enough to cater to a diverse range of dietary requirements.

In conclusion, the market for sandwich presses is evolving in response to consumer preferences that prioritize health, convenience, and style. As the industry continues to innovate, it’s clear that the future of sandwich press design will be defined by a blend of functionality, sustainability, and consumer appeal.

In the competitive landscape of the kitchen appliance industry, the emphasis on quality control and manufacturing excellence is paramount. A heavy-duty sandwich press factory must adhere to stringent standards to ensure that each product that leaves the assembly line meets the highest level of craftsmanship and reliability. Here’s an in-depth look at the critical aspects of quality control and manufacturing excellence in such a factory:

The factory employs a team of skilled engineers and technicians who are well-versed in the intricacies of sandwich press manufacturing. They are trained to monitor every stage of the production process, from the sourcing of raw materials to the final assembly and packaging.

Raw Material SelectionThe foundation of quality begins with the raw materials. The factory meticulously selects high-grade metals, such as stainless steel, for the construction of the sandwich press. These materials are not only durable but also resistant to rust and corrosion, ensuring that the presses are long-lasting.

Advanced Machining TechniquesOnce the materials are chosen, the factory employs state-of-the-art machining techniques to shape and form the components. CNC (Computer Numerical Control) machines are used to achieve precision cuts and intricate designs, which are crucial for the even distribution of heat and pressure during the cooking process.

Heat Distribution SystemThe heart of a sandwich press is its heat distribution system. The factory ensures that the heating elements are evenly spaced and that the press can reach and maintain consistent temperatures across its surface. This is achieved through rigorous testing and calibration, guaranteeing that every sandwich will be cooked to perfection.

Safety FeaturesSafety is a top priority in the manufacturing process. The factory integrates multiple safety features into the design of the sandwich press, including automatic shut-off mechanisms that activate if the press is left unattended or if the temperature exceeds safe limits. This not only protects the user but also prevents damage to the appliance.

Quality InspectionThroughout the manufacturing process, there are multiple checkpoints for quality inspection. Each component is examined for defects, and only those that meet the strictest standards are allowed to proceed to the next stage. This includes visual inspections, functional tests, and durability assessments.

Environmental ConsiderationsThe factory is committed to environmental sustainability. It uses energy-efficient machinery and minimizes waste during production. Recycling programs are in place to handle the disposal of materials that cannot be reused, and the factory is designed to reduce its carbon footprint.

Certifications and ComplianceTo maintain the highest standards, the factory holds various certifications, such as ISO 9001 for quality management systems and CE marking for compliance with European safety regulations. These certifications are not just symbols but are integral to the daily operations, ensuring that every sandwich press is a testament to excellence.

Employee Training and DevelopmentThe factory invests in the training and development of its employees. Regular workshops and seminars are conducted to keep the workforce updated with the latest manufacturing techniques and quality control processes. This ensures that the employees are equipped with the knowledge and skills to produce top-tier products.

Customer Feedback and Continuous ImprovementThe factory actively seeks customer feedback to understand the strengths and weaknesses of its products. This feedback is used to drive continuous improvement initiatives, where the manufacturing process is refined and enhanced based on real-world usage.

In conclusion, the heavy-duty sandwich press factory’s commitment to quality control and manufacturing excellence is evident in every aspect of its operations. From the careful selection of materials to the meticulous attention to detail during production, the factory ensures that each sandwich press is not just a product but a symbol of the highest standards in kitchen appliance manufacturing.

In today’s competitive culinary appliance market, the significance of branding and marketing cannot be overstated. From crafting a memorable brand identity to implementing effective marketing strategies, these elements are pivotal in distinguishing a heavy-duty sandwich press factory from its competitors. Here’s an exploration of the importance of branding and marketing in this niche:

Building a Strong Brand Identity: A brand identity is more than just a logo or a catchy slogan; it’s the essence of what a company stands for. For a heavy-duty sandwich press factory, this could mean emphasizing durability, innovation, and quality. A well-defined brand identity resonates with consumers, fostering trust and loyalty.

Targeting the Right Audience: Understanding your target audience is crucial. For heavy-duty sandwich presses, the market might include restaurants, cafes, and even home chefs who demand robust appliances for their high-volume cooking needs. Effective marketing ensures that these potential customers are reached through the right channels, be it social media, trade shows, or industry publications.

Differentiating from Competitors: With numerous brands vying for attention, a strong brand presence is essential to stand out. A factory specializing in heavy-duty sandwich presses might highlight unique features like adjustable heat settings, non-stick surfaces, or the ability to handle thick sandwiches. Marketing efforts should focus on showcasing these distinct advantages to potential buyers.

Enhancing Product Perception: The way a product is perceived by consumers can significantly impact its success. By investing in branding and marketing, a sandwich press factory can create a perception of premium quality and reliability. This perception can translate into higher sales and a premium price point for their products.

Utilizing Social Media and Digital Marketing: In the digital age, social media platforms have become powerful tools for branding and marketing. A factory can leverage these channels to share content that engages customers, such as behind-the-scenes glimpses, customer testimonials, and tutorials on how to use their sandwich presses effectively. This not only educates consumers but also builds a community around the brand.

Influencer Partnerships: Collaborating with influencers who align with the brand’s values can be a game-changer. Influencers can demonstrate the versatility and quality of the sandwich presses, reaching a broader audience and adding credibility to the product.

Event Sponsorship and Trade Shows: Participating in events and trade shows can increase brand visibility. A sandwich press factory can showcase their products, network with potential distributors, and gather valuable feedback from industry professionals and consumers.

Customer Experience and Service: Branding and marketing are not just about selling products; they’re also about building relationships. Providing exceptional customer service and ensuring a seamless buying experience can lead to positive word-of-mouth and repeat business.

Consistency Across Channels: A cohesive brand message across all marketing channels is key. From the website to packaging, the brand should maintain consistency in its visual identity, messaging, and overall tone to reinforce its image in the minds of consumers.

Measuring Success and Adaptation: The effectiveness of branding and marketing efforts should be regularly measured through analytics and customer feedback. This data allows the factory to adapt its strategies, refine its brand, and continue to meet the evolving needs and preferences of the market.

Long-Term Growth and Legacy: By investing in strong branding and marketing, a sandwich press factory can lay the foundation for long-term growth and a lasting legacy. A well-established brand can outlast trends and market fluctuations, ensuring a stable and profitable business.

Global Expansion: For a factory looking to expand into international markets, branding and marketing play a crucial role. Tailoring the brand message to resonate with different cultures and market segments is essential for successful global outreach.

In summary, branding and marketing are not just about promoting a product; they are about creating a story, a community, and a lasting impression. For a heavy-duty sandwich press factory, these efforts can be the difference between a product that sells and a brand that becomes synonymous with quality and innovation.

In the competitive landscape of the kitchen appliance industry, the rise of the heavy-duty sandwich press has not only introduced a new trend but also presented a host of challenges and opportunities. Navigating these is crucial for manufacturers looking to thrive in this niche market.

The demand for convenience and speed in meal preparation has surged, with sandwich presses becoming a staple in many kitchens. However, the market is not without its hurdles. From the need for innovation to meet consumer expectations to the challenges of sourcing high-quality materials, the path is fraught with complexities.

Manufacturers are under constant pressure to create sandwich presses that not only meet but exceed the expectations of health-conscious consumers. The demand for healthier, home-cooked meals has driven the industry to offer models with adjustable heat settings and non-stick surfaces, ensuring that users can enjoy their favorite sandwiches without the guilt of excessive oil or fat.

Another challenge lies in the supply chain. The global shortage of certain raw materials, such as metals and plastics, has impacted production timelines and costs. Factories must be agile and adaptable, finding alternative suppliers or materials to maintain their production schedules without compromising on quality.

On the flip side, opportunities abound. The rise of e-commerce has expanded the reach of sandwich press manufacturers. Online marketplaces provide a platform to connect with a global audience, allowing for direct sales and personalized marketing campaigns. This direct engagement with customers can lead to valuable feedback and insights that drive product development.

The industry also benefits from the growing trend of home entertaining and social gatherings. Sandwich presses are perfect for creating impressive and appetizing displays at casual get-togethers. This trend has opened up new avenues for marketing and product diversification, with some brands even offering presses designed for specific types of bread or fillings.

Furthermore, the integration of technology into kitchen appliances has presented a golden opportunity. Smart sandwich presses with digital interfaces and Bluetooth connectivity allow users to control their cooking experience remotely. This added functionality can attract tech-savvy consumers who are looking for the latest in kitchen gadgetry.

Sustainability is another area ripe with potential. As consumers become more environmentally conscious, there’s a growing demand for eco-friendly products. Manufacturers that can produce sandwich presses with sustainable materials and energy-efficient designs will find a loyal customer base.

In terms of design, the industry is witnessing a shift towards versatility. Sandwich presses are no longer just for sandwiches; they’re being used to make paninis, wraps, and even pizzas. This evolution has prompted manufacturers to create models with removable inserts and adjustable heating elements to cater to a wider range of culinary desires.

Moreover, the opportunity to collaborate with food influencers and chefs can significantly boost brand visibility. Endorsements from these figures can lend credibility to a product and create a buzz around the brand.

Lastly, the potential for international expansion is substantial. As the popularity of the sandwich press continues to grow, there’s a clear opportunity to tap into new markets, especially in regions where fast food is a cultural staple. Adapting to local tastes and preferences while maintaining the core product features is key to successful global penetration.

In summary, while the heavy-duty sandwich press industry faces challenges such as material shortages and the need for innovation, it also offers a wealth of opportunities for growth and success. By embracing technological advancements, focusing on sustainability, and understanding consumer preferences, manufacturers can navigate the market’s complexities and capitalize on the exciting possibilities that lie ahead.

In the bustling world of kitchen appliances, several heavy-duty sandwich press manufacturers have carved out their niches, not just by producing high-quality products but by adapting to market demands and consumer preferences. Let’s take a look at a few case studies of these successful manufacturers.

The Italian-based company, Gaggia, has long been associated with premium coffee machines, but their foray into the sandwich press market has been equally impressive. They’ve managed to blend their expertise in engineering with the art of making delicious sandwiches. Their heavy-duty sandwich presses are known for their sturdy build and precision, ensuring even heating and consistent pressing for the perfect toast and melt.

Another standout in the industry is Hamilton Beach, a brand that has been around since the 1940s. They’ve leveraged their extensive experience in kitchen appliances to create heavy-duty sandwich presses that cater to a wide range of consumers. Their models, like the Hamilton Beach 25401, offer features such as non-stick surfaces, adjustable heat settings, and removable drip trays, making them both user-friendly and convenient.

Kitchenaid, a well-known name in kitchenware, has also made waves with their heavy-duty sandwich presses. The Kitchenaid 8-in-1 Sandwich Maker stands out for its versatility, allowing users to create not just sandwiches but also panini, grilled cheese, and even desserts. This multifunctional approach has helped Kitchenaid appeal to a broad audience looking for a versatile kitchen gadget.

Cuisinart, another household name, has introduced several heavy-duty sandwich presses that have been met with acclaim. The Cuisinart GR-4N Round Griddler Panini Press, for example, is not only a sandwich press but also a grill, offering the versatility to cook a variety of foods. The even heat distribution and the ability to sear and lock in flavors have made this product a favorite among culinary enthusiasts.

The German company, Tefal, has also made its mark with their heavy-duty sandwich presses. Known for their durability and efficiency, Tefal’s presses feature non-stick coatings that ensure easy cleanup and consistent cooking. Their sandwich presses often come with adjustable temperature controls, allowing users to tailor the cooking process to their preferred texture and taste.

In the case of Sunbeam, their heavy-duty sandwich presses are a testament to their commitment to innovation. The Sunbeam Sandwich Press features a unique “Stay Open” lid that keeps the press open for easy filling, and its automatic shut-off feature adds an extra layer of safety. These thoughtful design elements have made Sunbeam’s products a staple in many homes.

Each of these case studies highlights the unique selling points that have helped these manufacturers succeed in the heavy-duty sandwich press market. From innovative features and versatility to durability and safety, these brands have managed to capture the hearts and minds of consumers who are looking for a reliable and high-quality sandwich-making tool. Whether it’s through a focus on premium materials, user convenience, or the ability to create a variety of dishes, these successful manufacturers have proven that the art of sandwich making can be taken to new heights with the right equipment.

In the ever-evolving landscape of kitchen appliances, the sandwich press has carved out a niche for itself, especially in the Western markets. From the humble days of a simple gadget to a must-have kitchen tool, the sandwich press has seen a surge in popularity. The convenience it offers, coupled with the endless possibilities of customization, has made it a staple in many homes. This trend is not just a fad; it’s a testament to the changing culinary preferences and the need for quick, delicious meals.

As the demand for sandwich presses grows, so does the competition. Manufacturers are constantly seeking ways to innovate and stand out in a crowded market. This is where the heavy duty sandwich press comes into play, offering durability and reliability that appeal to both casual and professional chefs. Let’s delve into the key features that define a heavy duty sandwich press factory.

A heavy duty sandwich press factory is equipped with state-of-the-art machinery that can handle the rigors of high-volume production. These presses are designed to withstand constant use, ensuring that they can be used in busy restaurants, catering services, or even in the home kitchen. The build quality is often superior, with stainless steel components that resist rust and corrosion, making them a long-lasting investment.

One of the standout features of a heavy duty sandwich press is its heat distribution capabilities. These presses are engineered to ensure even heat distribution across the sandwich, which is crucial for achieving that perfect golden-brown crust. Advanced heating elements and non-stick surfaces are commonly used to facilitate this process, ensuring that each sandwich comes out perfectly cooked.

Another important aspect is the ease of use. Heavy duty sandwich presses often come with intuitive controls and safety features that make them accessible to a wide range of users. From simple on/off switches to adjustable temperature settings, these presses cater to both beginners and seasoned cooks. The inclusion of removable plates for easy cleaning is also a convenience that cannot be overlooked.

Innovation in design doesn’t stop at the basic functionalities. Many heavy duty sandwich presses now come with additional features that enhance the user experience. Some models include a drip tray to catch any excess grease, while others offer variable pressure settings for different types of sandwiches. Some presses even come with built-in timers, so you can set the perfect cooking time for each sandwich, ensuring consistency.

As for the market trends, there’s a noticeable shift towards healthier eating habits. Consumers are increasingly interested in controlling the ingredients they use, leading to a demand for sandwich presses that can accommodate whole-grain breads, lean proteins, and fresh vegetables. This has spurred the development of presses with larger plates and more versatile cooking surfaces.

Consumer preferences are also driving the demand for eco-friendly and sustainable products. Sandwich press factories are responding by using recycled materials in their manufacturing processes and designing presses that are energy-efficient. The market is also seeing a rise in smart appliances, with some sandwich presses offering connectivity to smartphones for remote temperature control and recipe suggestions.

The quality control in a heavy duty sandwich press factory is stringent. Each unit is tested for durability, heat distribution, and safety before it leaves the production line. Quality assurance teams inspect every aspect of the manufacturing process, from raw material selection to final assembly, to ensure that only the best products reach the consumer.

The importance of branding and marketing in the kitchen appliance industry cannot be overstated. In a market filled with options, a strong brand can make all the difference. Effective branding helps to differentiate a product and build trust with consumers. Marketing strategies are crucial in reaching the right audience and conveying the unique selling points of a sandwich press.

Branding often involves a combination of factors, including a memorable logo, a clear value proposition, and a cohesive brand voice. Marketing campaigns are designed to highlight the benefits of the product, whether it’s the convenience of a quick breakfast or the joy of homemade meals. Social media platforms have become key tools for reaching consumers, with engaging content that showcases the versatility of sandwich presses.

Challenges in the industry are multifaceted. The rapid pace of technological advancements means that manufacturers must continually innovate to keep up with changing consumer demands. Additionally, competition is fierce, and pricing strategies can be complex. There’s also the environmental factor to consider, as the industry must find ways to reduce its carbon footprint while maintaining profitability.

Despite these challenges, there are numerous opportunities. The rise of food trucks and pop-up restaurants has created a new market for portable and easy-to-use kitchen appliances, including sandwich presses. The growing interest in home cooking and the need for convenience foods has also expanded the consumer base. Furthermore, the integration of technology into kitchen appliances has opened up new avenues for innovation.

Case studies of successful heavy duty sandwich press manufacturers often reveal a commitment to research and development, a focus on customer satisfaction, and a willingness to adapt to market changes. Companies like XYZ Sandwich Press have become household names by offering high-quality products with cutting-edge features and exceptional customer service.

In conclusion, the future of sandwich press production looks bright. As consumer preferences continue to evolve, manufacturers will need to stay agile and responsive. The key will be to balance innovation with quality and to leverage the power of branding and marketing to stand out in a competitive market. With the right approach, the sandwich press industry is poised for continued growth and success.