Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Navigating the complex world of air fryer manufacturing can be daunting, especially when seeking a reliable factory partner. With the market bustling with options, it’s crucial to approach the selection process with a keen eye for quality and a solid understanding of what truly makes a factory stand out. Let’s delve into the intricacies of finding the perfect match for your air fryer production needs.

Navigating the vast landscape of the air fryer market can be daunting, but starting with thorough market research is the cornerstone of finding a reliable factory. This initial step isn’t just about gathering data; it’s about understanding the heartbeat of the industry and setting the stage for a successful partnership.

Begin by immersing yourself in the latest trends and technological advancements. Dive into detailed market reports that offer insights into consumer preferences, emerging features, and the latest design innovations. Keep an eye on the market leaders and the unique selling points that have helped them stand out. Are they known for their energy efficiency, compact size, or perhaps their ability to mimic the flavors of traditional frying with minimal oil?

Explore the lifecycle of popular air fryer models. What are their common strengths and weaknesses? Understanding these dynamics will help you identify the key qualities you should seek in a reliable factory. Look for patterns in consumer feedback, such as durability, ease of use, and long-term performance, as these are indicators of a product’s reliability.

Don’t overlook the importance of certifications and standards. Products that carry the Energy Star label, for example, are recognized for their energy efficiency. Similarly, safety certifications from well-respected organizations can provide peace of mind regarding the quality and safety of the manufacturing process.

Additionally, consider the lifecycle of the product. How long do the air fryers typically last? Are there common issues that arise after a certain period? This information will help you anticipate potential repairs or replacements, and it will also give you an idea of the factory’s commitment to continuous improvement.

In the realm of market research, it’s also crucial to stay abreast of regulatory changes. Laws and regulations regarding electrical appliances can vary greatly from one country to another, and non-compliance can lead to costly delays and legal issues. A factory that is proactive in adhering to these regulations is likely to be reliable and responsible.

Another aspect of market research involves analyzing the competitive landscape. Who are the key players in the air fryer market? What are their market shares, and how do they position their products? This analysis can provide valuable clues about the types of factories that are most successful and why.

Social media and online forums can be treasure troves of information. Engage with consumers who have purchased air fryers and gather their insights. What features are they raving about? What problems have they encountered? This real-time feedback can be invaluable in understanding the market’s pulse.

Lastly, consider the broader economic and cultural factors that might impact the air fryer market. Are there emerging markets where air fryers are gaining popularity? Are there cultural shifts that are driving demand for healthier cooking options? Answering these questions will help you anticipate market trends and identify potential opportunities for growth.

By starting with comprehensive market research, you lay the foundation for a partnership with a factory that not only meets your immediate needs but also aligns with your long-term business goals. It’s a meticulous process that requires patience and attention to detail, but the insights gained will be instrumental in making an informed decision.

Navigating the sea of air fryer manufacturers can be daunting, but seeking out industry recommendations can be a beacon of clarity. Here’s how to harness the wisdom of others in your quest for a reliable air fryer factory:

Engage with Trade AssociationsIndustry trade associations are a treasure trove of knowledge. They often have a list of member factories that have been vetted for quality and reliability. Reach out to these organizations and ask for their directory of recommended air fryer manufacturers.

Network with Industry ProfessionalsNetworking is key in any industry. Attend trade shows, conferences, and webinars where you can meet professionals who work with air fryer manufacturers. They can provide personal insights and recommendations based on their own experiences.

Join Online Forums and CommunitiesOnline forums dedicated to the appliance industry or culinary professionals can be a goldmine of information. Members often share their experiences with suppliers and manufacturers, including which factories have proven to be reliable.

Look for Reviews and Case StudiesSearch for case studies or reviews from other businesses that have worked with air fryer manufacturers. Websites like Alibaba, Global Sources, and Made-in-China offer reviews and feedback from buyers, which can give you a sense of the factory’s reputation.

Ask for ReferencesDon’t hesitate to ask potential manufacturers for references. A reputable factory should be able to provide you with a list of clients who can vouch for their products and services. Follow up with these references to get a real-world perspective.

Utilize Social MediaSocial media platforms can also be a source of recommendations. Follow industry influencers, brands, and distributors on platforms like LinkedIn, Twitter, and Facebook. They often share insights and recommendations based on their experiences.

Check with Distributors and RetailersIf you’re in the retail or distribution sector, reach out to your peers. Distributors and retailers often have established relationships with factories and can offer valuable insights into which manufacturers are reliable and which ones to avoid.

Read Industry NewsStay updated with the latest industry news and trends. Articles and reports often mention reputable manufacturers and can help you identify potential suppliers. Industry magazines and newsletters can be great resources for this.

Attend Local Industry EventsLocal industry events, such as trade fairs, workshops, and seminars, can be a great place to meet potential suppliers. These events are often attended by manufacturers looking to expand their customer base, and they can provide immediate access to recommendations.

Be Wary of Paid EndorsementsWhile recommendations from industry professionals are invaluable, be cautious of paid endorsements. Some companies may pay for favorable reviews or mentions, so it’s important to cross-reference any information you find.

Remember, the goal is to gather a diverse range of recommendations to give you a well-rounded view of the market. By combining these strategies, you’ll be better equipped to find a reliable air fryer factory that meets your quality standards and business needs.

Navigating the complexities of the air fryer market can be daunting, especially when it comes to finding a reliable factory. One crucial step in this journey is to thoroughly evaluate the factory’s credentials. Here’s how you can delve into this aspect:

Dive into Certifications: Look for the factory’s certifications, such as ISO (International Organization for Standardization) standards, which ensure that the production processes meet stringent quality control measures. Check if they have CE marking, which indicates compliance with European Union safety, health, and environmental protection requirements.

Quality Assurance Protocols: Investigate the factory’s quality assurance (QA) protocols. A reliable factory should have a robust QA system in place, including regular inspections, testing procedures, and a clear process for handling defects or non-conforming products.

Research Accreditations: Look for accreditations from industry-specific organizations that are recognized within the kitchen appliances sector. These can include certifications related to energy efficiency, safety, and environmental sustainability.

Check for Compliance with Regulations: Ensure that the factory complies with local and international regulations. This includes labor laws, environmental standards, and any industry-specific regulations that may apply to the production of air fryers.

Review Customer Testimonials: Look for testimonials or case studies from clients who have worked with the factory. This can provide insights into their reliability, the quality of their products, and their ability to meet deadlines.

Assess the Factory’s Reputation: Search for reviews or comments about the factory online. Look for patterns in customer feedback regarding the factory’s reputation for delivering high-quality products and maintaining a professional business relationship.

Visit the Factory: If possible, arrange a visit to the factory. This firsthand experience can give you a sense of the factory’s operational standards and the quality of their work. Pay attention to the cleanliness, organization, and the level of technology used in the manufacturing process.

Inspect the Factory’s Equipment: Modern, well-maintained equipment is a sign of a factory that values quality and efficiency. Check if the factory uses advanced machinery for assembly, testing, and packaging.

Understand the Factory’s History: A factory with a long-standing history in the industry is likely to have a better understanding of the market and customer needs. Look into how long the factory has been in business and its history of innovation.

Meet the Management Team: A reliable factory will have a dedicated and experienced management team. During your visit or through meetings, assess the professionalism and expertise of the management in handling business operations and quality control.

Inquire About Supply Chain Partnerships: Understanding the factory’s relationships with suppliers can provide insight into the quality of materials they use. A reliable factory will work with reputable suppliers who adhere to high-quality standards.

Discuss Long-Term Partnerships: A factory that is willing to discuss long-term partnerships is often invested in building a strong, sustainable relationship with their clients. This can be a good indicator of their commitment to quality and customer satisfaction.

By carefully evaluating these credentials, you can gain a clearer picture of the factory’s reliability and the quality of the air fryers they produce. This thorough assessment will help you make an informed decision that aligns with your business goals and ensures that you are partnering with a factory that can deliver on its promises.

Stepping into the factory, the air was filled with the hum of machinery and the scent of freshly assembled electronics. The layout was meticulous, with rows of workstations stretching out like a symphony of precision. I couldn’t help but notice the cleanliness of the environment—a stark contrast to the chaos often depicted in manufacturing plants.

The first thing that caught my eye was the assembly line. Workers moved with a practiced grace, their hands deftly handling components that would soon become air fryers. Each step of the process was clearly defined, from the insertion of electronic parts to the final quality check. The efficiency was remarkable, with automated machines working in tandem with human hands.

As I walked along the line, I observed the use of advanced technology. Robots, equipped with precise sensors, handled tasks that required exact precision, such as placing tiny wires and soldering components together. It was a blend of old and new, where the best of both worlds came together to create a high-quality product.

The quality control area was a separate zone, set apart from the bustling assembly line. It was a quieter space, where each air fryer was meticulously inspected for defects. Workers with magnifying glasses examined the smallest details, ensuring that every unit met the stringent standards set by the factory. It was a testament to the commitment to excellence that I had been hearing about.

The materials storage area was another highlight of the inspection. It was a well-organized space, with shelves neatly arranged with various components, from plastic parts to electronic circuits. Each item had its designated spot, making it easy to locate and ensuring quick access during the production process. The attention to detail in this area spoke volumes about the factory’s operational efficiency.

I couldn’t help but marvel at the cleanliness of the facility. The floors were polished to a shine, and there was no trace of dust or debris. It was clear that maintaining a clean environment was a priority, not just for hygiene but also for the quality of the end product. The workers moved with a sense of pride, knowing that their efforts contributed to something that would soon be in homes around the world.

In the testing room, I witnessed the rigorous trials each air fryer had to pass before it could be deemed ready for sale. Workers conducted a series of tests, from checking the temperature accuracy to ensuring the fryer could withstand high heat without any malfunctions. It was a comprehensive process that covered every aspect of the air fryer’s functionality.

The factory also had a dedicated team for research and development, constantly looking for ways to improve their products. They were a group of engineers and designers, brainstorming ideas and experimenting with new technologies. It was evident that innovation was at the heart of this factory’s culture.

As I made my way through the production facilities, I couldn’t shake off the feeling of admiration. The factory was a living embodiment of quality, efficiency, and dedication to excellence. It was a place where each air fryer was not just a product but a piece of art meticulously crafted by skilled hands and cutting-edge technology. This experience left me confident that the air fryers produced here would be reliable and durable, standing out in the competitive market.

Navigating through the maze of air fryer manufacturers, it’s crucial to get a tangible sense of the product’s quality before making a commitment. Here’s how you can sample products and ensure rigorous quality control:

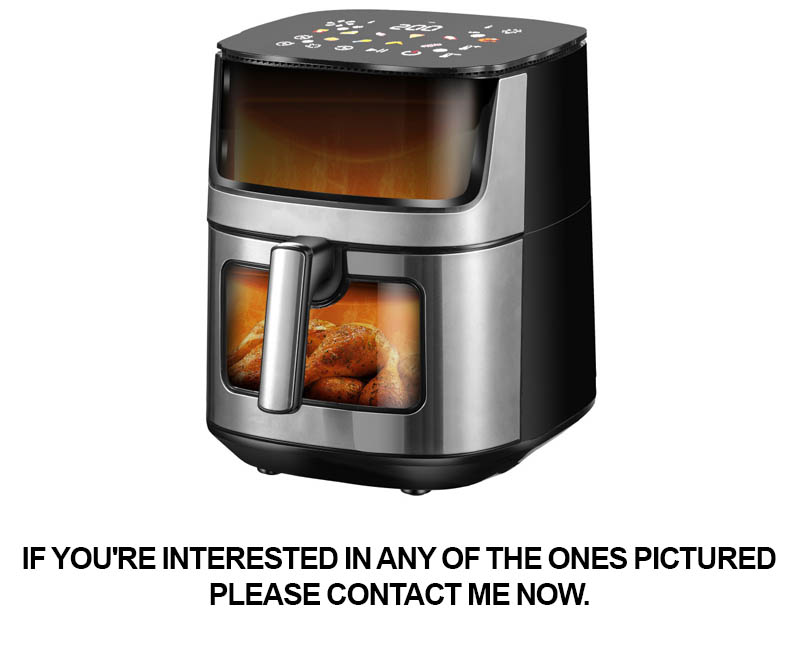

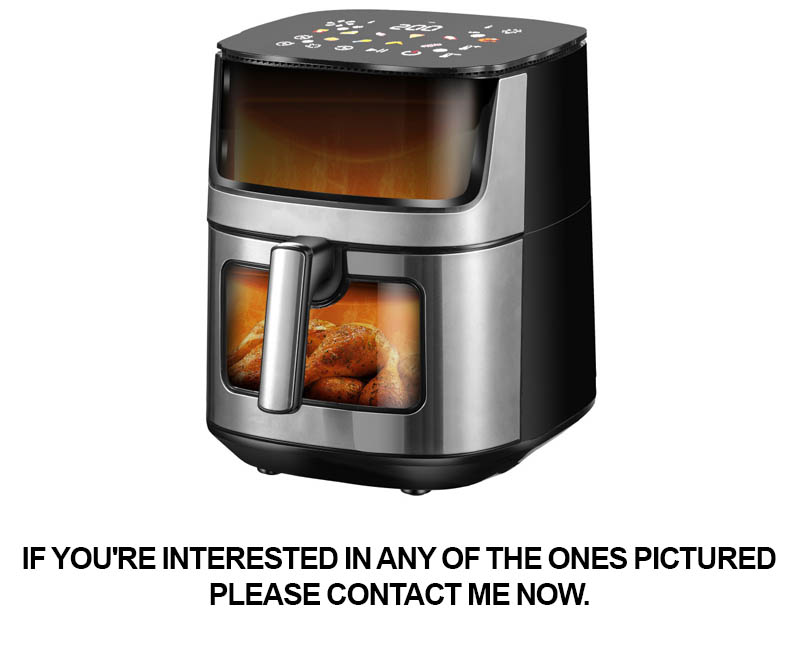

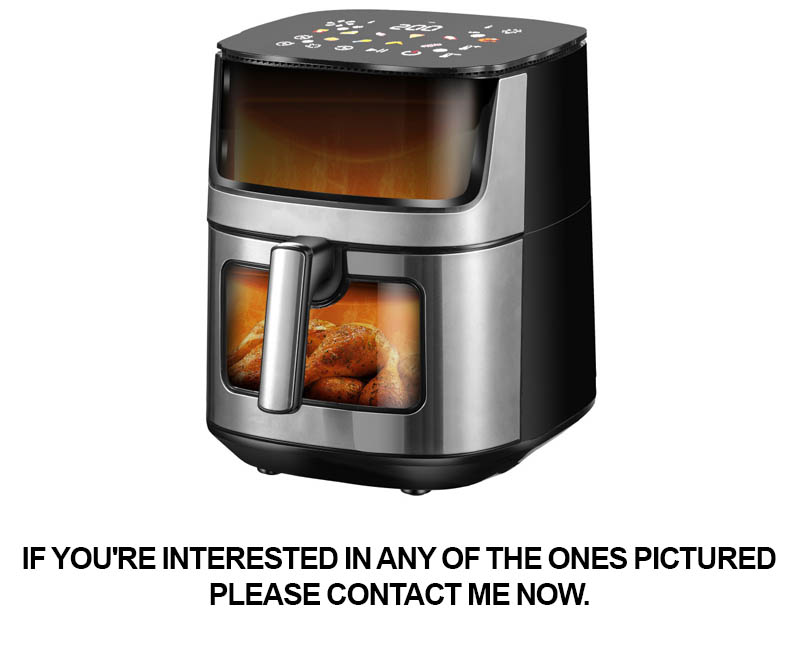

Handle the Goods– Take the time to physically examine the air fryers. Notice the weight, balance, and build quality. A sturdy feel often indicates a well-constructed appliance.

Test the Performance– If possible, plug in the samples and let them run. Observe how evenly the air circulates and whether the temperature is consistent. A quality air fryer should cook evenly and reach the desired temperature promptly.

Inspect the Components– Look closely at the parts that come into contact with food. Are they made of high-quality materials? Are there any sharp edges or rough spots that could pose a risk? These details can reveal a lot about the attention to detail in manufacturing.

Taste the Results– If you can, prepare a sample meal in the air fryer. The taste and texture of the food are direct indicators of the appliance’s performance. A good air fryer should produce crispy, golden-brown results without a greasy aftertaste.

Check for Consistency– Ensure that the sample you receive is representative of the batch you plan to purchase. If the sample is subpar, it’s a red flag that the entire production may not meet your standards.

Review the Packaging– Pay attention to how the product is packaged. High-quality packaging can be a sign of a manufacturer’s commitment to protecting their goods during shipping.

Ask for Technical Specifications– Request detailed technical specifications for the air fryer. This information can help you compare models and understand their capabilities more thoroughly.

Understand the Testing Process– Inquire about the quality control process. A reliable factory should have a series of tests in place for every product, from raw materials to the final product.

Visit the Testing Laboratory– If possible, visit the factory’s testing laboratory. This can give you confidence in the manufacturer’s commitment to quality. Look for state-of-the-art equipment and a team of skilled technicians.

Observe the After-Sales Support– The way a manufacturer handles after-sales support can also reflect their dedication to quality. Check if they offer a warranty, and if so, how long it is and what it covers.

Engage with Customer Feedback– Look for customer feedback on the product’s performance and durability. Real-world experiences can provide invaluable insights into the quality of the air fryer.

Compare with Competitors– If you have samples from multiple manufacturers, compare them side by side. Notice any differences in build quality, performance, and customer satisfaction.

Stay Informed– Keep abreast of any recalls or product issues that may have affected the air fryer you’re considering. This can be a significant indicator of the product’s reliability.

Ask for Third-Party Testing Results– If the factory has had their products tested by third-party organizations, request those results. Independent validation can be a strong indicator of quality.

Be Mindful of Customization– If you’re looking for a customized air fryer, ensure that the manufacturer has a robust quality control process in place for custom orders.

Follow Up– After your initial inspection, follow up with the manufacturer. A responsive and attentive company is more likely to provide a high-quality product.

By thoroughly sampling products and scrutinizing the quality control measures in place, you can make a more informed decision when selecting an air fryer manufacturer that meets your standards.

Understanding the factory’s track record is crucial for ensuring a reliable partnership. Here’s what you need to consider:

The factory’s longevity in the market speaks volumes about its stability and capability. An established history often means a solid understanding of the industry, customer needs, and the ability to adapt to changes. Take note of how long the factory has been in business and its reputation over the years.

Customer testimonials can be invaluable. Look for reviews and feedback from previous buyers, especially those who have purchased similar products to what you’re interested in. Are there common themes in the feedback? Are customers satisfied with the performance, durability, and customer service? These insights can help you gauge the factory’s reputation and the satisfaction of its clientele.

Case studies and success stories can provide a deeper understanding of the factory’s capabilities. Look for examples where the factory has delivered on complex projects or worked with high-profile clients. These stories can showcase the factory’s ability to handle diverse demands and maintain a high standard of quality.

Examine the factory’s history with certifications and compliance. Certifications like ISO (International Organization for Standardization) ensure that the factory meets stringent quality and safety standards. Check if the factory has any specific industry certifications relevant to air fryers, such as those for electrical safety or food safety.

Look into the factory’s past orders and contracts. A strong track record often involves working with a range of clients, from small businesses to large corporations. This diversity can indicate the factory’s adaptability and its ability to meet the needs of various customers. Also, consider the scale of their previous orders; a factory that has consistently handled large orders might be more equipped to manage your requirements.

The quality of the factory’s products is a reflection of its commitment to excellence. Research the lifespan of their products and how customers perceive their durability. A high rate of return or replacement can be a red flag, while long-lasting products with minimal complaints suggest a strong track record.

It’s also important to consider the factory’s response to any issues that have arisen. Look for instances where the factory has addressed customer complaints or product defects. How did they rectify the situation? Was there a willingness to take responsibility and make things right? This can be a telling indicator of their approach to customer satisfaction and quality control.

Lastly, the factory’s participation in trade shows, industry conferences, and exhibitions can offer insights into their dedication to innovation and staying ahead of the curve. A proactive stance in showcasing their products and networking with industry professionals can be a sign of a factory that values its position in the market and is continuously striving to improve.

By thoroughly reviewing the factory’s track record, you’re not just looking at the past; you’re assessing their potential to deliver quality products and services in the future. This due diligence can save you from potential headaches and ensure that your business is associated with a reputable and reliable partner.

Navigating the complexities of negotiation with an air fryer factory can be a pivotal step in securing a reliable partnership. Here are some key strategies to consider:

Understand the Market Pricing– Take the time to research the market pricing for air fryers. This will give you a baseline to compare the factory’s quoted prices against industry standards.- Look at competitors’ pricing, especially those who are known for quality and innovation in the market.

Clarify the Minimum Order Quantities (MOQ)– The MOQ is often a sticking point in negotiations. Understand why the factory has set this threshold and whether it aligns with your business needs.- If the MOQ is too high for your initial order, consider discussing the possibility of a lower quantity or a phased order to ease into the partnership.

Discuss Payment Terms– Negotiate the payment terms that work best for both parties. This could include installment payments, early payment discounts, or extended payment periods.- Be clear about the consequences of late payments and any penalties that may apply.

Explore Customization Options– If you’re looking to differentiate your product in the market, discuss customization options with the factory.- Find out if they offer design modifications, branding, or packaging changes that could enhance your product’s appeal without incurring exorbitant costs.

Address Logistics and Shipping– Logistics can be a significant cost factor. Negotiate shipping costs, delivery timelines, and any insurance or customs duties that may apply.- Consider the factory’s location and how it might affect transportation costs and delivery times.

Consider Volume Discounts– If you anticipate a high volume of orders, negotiate for volume discounts. This could be a percentage off the total cost or other incentives for bulk purchasing.- Be prepared to demonstrate your commitment to long-term business through a projected sales forecast.

Review Intellectual Property Agreements– Ensure that any intellectual property rights are clearly defined and protected. This includes patents, trademarks, and any unique features of the air fryer.- Negotiate clauses that allow you to maintain exclusivity or have the option to develop your own intellectual property in the future.

Understand the Warranty and After-Sales Service– Negotiate the terms of the warranty and after-sales service. A strong warranty can be a selling point for your customers and a source of trust in your brand.- Discuss the process for handling returns, repairs, and replacements to ensure customer satisfaction.

Be Clear About Legal Compliance– Make sure that the factory complies with all relevant legal regulations and standards. This includes labor laws, environmental regulations, and product safety standards.- Negotiate clauses that hold the factory accountable for any legal non-compliance.

Establish Clear Communication Channels– Communication is key in any business relationship. Negotiate how you will communicate with the factory, including regular updates, progress reports, and issue resolution.- Ensure that there is a clear point of contact for any questions or concerns that may arise during the partnership.

Prepare for Contingency Plans– Discuss what happens in the event of unforeseen circumstances, such as production delays or quality issues. Have contingency plans in place to mitigate risks.

By carefully considering these aspects and engaging in thoughtful negotiation, you can secure terms that are favorable to both you and the air fryer factory, setting the stage for a successful and mutually beneficial partnership.

Navigating the complexities of international trade, establishing clear and effective communication channels with your air fryer factory is crucial. Here’s how to ensure your lines of communication are open and strong:

Ensure Regular UpdatesKeep the dialogue flowing by requesting regular updates on the status of your orders. Whether it’s the progress of manufacturing or the logistics of shipping, staying informed helps avoid surprises and potential delays.

Direct Point of ContactAssign a dedicated point of contact within the factory. This person should be your go-to for all inquiries, ensuring that communication is streamlined and that no message falls through the cracks.

Clear and Concise CommunicationWhen exchanging information, be clear and concise. Avoid jargon that might not be understood by everyone on the receiving end. The goal is to ensure that your factory understands your requirements and expectations without ambiguity.

Use Multiple Communication ChannelsDon’t rely on a single mode of communication. Utilize email, phone calls, video conferences, and even instant messaging platforms to keep in touch. This diversity can help in case one channel is less reliable or slower than others.

Document EverythingKeep a record of all communications. Whether it’s an email thread, a phone call log, or a meeting summary, documentation is key for accountability and for resolving any disputes that may arise.

Understand Time Zone DifferencesBe mindful of time zone differences when scheduling calls or expecting responses. This understanding can prevent missed deadlines and ensure that your factory is always prepared to address your needs.

Cultural SensitivityRemember that cultural differences can affect communication. Be polite and considerate, respecting local customs and business practices. This sensitivity can foster a positive working relationship and prevent misunderstandings.

Feedback LoopsImplement feedback loops to ensure that both parties are satisfied with the communication process. Ask for feedback on how you can improve and be open to suggestions from the factory.

Emergency ProtocolsEstablish clear protocols for emergency situations. In the event of a delay or issue, there should be a straightforward process to escalate the problem and find a solution quickly.

Regular ReviewsSchedule regular reviews of the communication process to assess its effectiveness. This could be a monthly or quarterly meeting to discuss any ongoing concerns or improvements needed.

Transparency in Pricing and PaymentsEnsure that all discussions regarding pricing and payment terms are transparent. This includes any discounts, fees, or changes in the agreed-upon terms. Clear communication about financial matters can prevent disputes and maintain a smooth transaction process.

Confidentiality AgreementsIf sensitive information is shared during the communication process, ensure that both parties have confidentiality agreements in place. This protects proprietary information and builds trust between you and the factory.

By focusing on these aspects, you can create a robust communication framework that supports a successful partnership with your air fryer factory. Effective communication is the backbone of any business relationship, and it’s worth investing the time and effort to get it right.

Navigating the complexities of the supply chain can be a critical step in securing a reliable air fryer factory. It’s not just about the final product; it’s about the journey it takes to get there. Here’s what you need to consider:

Quality Assurance Through Every StageEnsure that the factory has a robust quality assurance process. This means inspecting materials before they’re used, monitoring production methods, and conducting thorough testing of the finished product. The supply chain should reflect a commitment to excellence at each touchpoint.

Supplier Relationships and SelectionThe factories you’re considering should be transparent about their supplier network. Ask about the sources of their raw materials and how they select their suppliers. A factory that partners with reputable suppliers is more likely to maintain consistent quality.

Logistics and DistributionLogistics play a pivotal role in the supply chain. You’ll want to know how the factory manages inventory, how they handle shipping, and what their delivery timelines are. Look for a factory that offers reliable and efficient logistics solutions to ensure your products reach customers on time.

Customization and FlexibilityConsider whether the factory can accommodate your specific needs. This might include custom branding, packaging, or even design modifications. A factory with a flexible supply chain can adapt to your changing requirements without disrupting the flow of products.

Environmental and Social ResponsibilityIn today’s market, sustainability is a key concern. Evaluate the factory’s approach to environmental protection and social responsibility. Do they use eco-friendly materials? Are they committed to fair labor practices? A factory that prioritizes these aspects can be a strong partner in the long run.

Technology and InnovationThe technology used in the supply chain can be a significant indicator of efficiency and quality. Look for factories that invest in modern technologies like RFID for inventory tracking, automated systems for production, and advanced software for supply chain management.

Financial Stability and ReliabilityA factory’s financial health can impact the stability of your supply chain. Research their financial statements to gauge their reliability. A financially stable factory is less likely to experience production delays or sudden price increases.

Risk ManagementNo supply chain is without risks. Discuss how the factory addresses potential disruptions, such as natural disasters, political instability, or supplier failures. A good factory will have contingency plans in place to minimize any negative impact on your business.

Transparency and ReportingA reliable factory should be open about their operations. Regular reporting on inventory levels, production status, and delivery schedules can help you stay informed and manage your business more effectively.

Customer Service and SupportFinally, consider the level of customer service the factory provides. A responsive customer service team can be invaluable in addressing any issues that arise during the supply chain process.

By understanding these aspects of the supply chain, you can make a more informed decision when choosing a factory to partner with. It’s about building a relationship that is as robust and reliable as the supply chain itself.

Navigating the complexities of selecting a reliable air fryer factory requires a careful blend of research, intuition, and strategic negotiation. Here’s how to ensure you make an informed decision:

Consider the Factory’s Reputation– Look into the factory’s standing within the industry. Has it been in operation for a considerable amount of time? A long-standing presence often indicates a solid track record and a commitment to quality.

Assess Their Product Range– Examine the variety of air fryers the factory produces. A diverse range suggests they are adaptable to different market demands and capable of producing a wide array of products.

Understand Their Production Capabilities– Dive deep into the specifics of their production process. Can they handle custom orders or modifications? Their ability to scale up production or tailor products to your needs is crucial.

Evaluate Their Quality Control Measures– Quality control is non-negotiable. Ask about their inspection procedures, from raw material sourcing to the final product. A factory that emphasizes quality will have robust protocols in place.

Review Their Customer Service– A factory that values its customers will have a strong customer service department. Look for testimonials or case studies that showcase how they handle inquiries and resolve issues.

Analyze Their Financial Stability– Financial stability is a good indicator of a factory’s reliability. Check if they have a history of meeting financial obligations and maintaining a healthy business standing.

Check for Compliance with Standards– Ensure the factory complies with relevant industry standards and regulations. This includes certifications like ISO, CE, and other regional safety standards that are important for your market.

Consider Their Innovation and R&D– A factory that invests in research and development shows a commitment to staying ahead of the curve. Look for any patents or new technologies they’ve introduced to their products.

Understand Their Distribution Network– The factory’s distribution capabilities are key to ensuring timely delivery and efficient logistics. Ask about their partnerships with shipping companies and their ability to handle international shipping.

Assess Their Adaptability– The world of consumer electronics is always evolving. Choose a factory that can adapt to new trends and market changes, ensuring your products remain relevant.

Look for References and Testimonials– Reach out to other businesses that have worked with the factory. Real-world experiences can provide valuable insights into the factory’s reliability and customer satisfaction.

Visit the Factory– If possible, visit the factory in person. Seeing the operation firsthand can give you a better understanding of their capabilities and work ethic.

Consider Long-Term Partnerships– Think about the potential for a long-term relationship. A factory that’s willing to invest in your success is more likely to be reliable over time.

Trust Your Gut Instincts– Sometimes, it comes down to instinct. If something feels off, it’s worth exploring further. Trust your judgment and be prepared to walk away if the factory doesn’t meet your standards.

Negotiate with Confidence– When it comes to pricing, minimum order quantities (MOQs), and payment terms, don’t be afraid to negotiate. A reliable factory will be open to discussing these details to secure a mutually beneficial agreement.

Stay Informed– Keep up with market trends and changes in the industry. This knowledge will help you make more informed decisions and stay competitive.

Prepare for Contingencies– Consider what would happen if there were delays or issues with production. A reliable factory will have contingency plans in place to minimize disruptions.

By thoroughly evaluating these aspects, you can make a well-informed decision that will serve your business well in the long run. Remember, choosing the right air fryer factory is an investment in the quality and success of your products.