Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

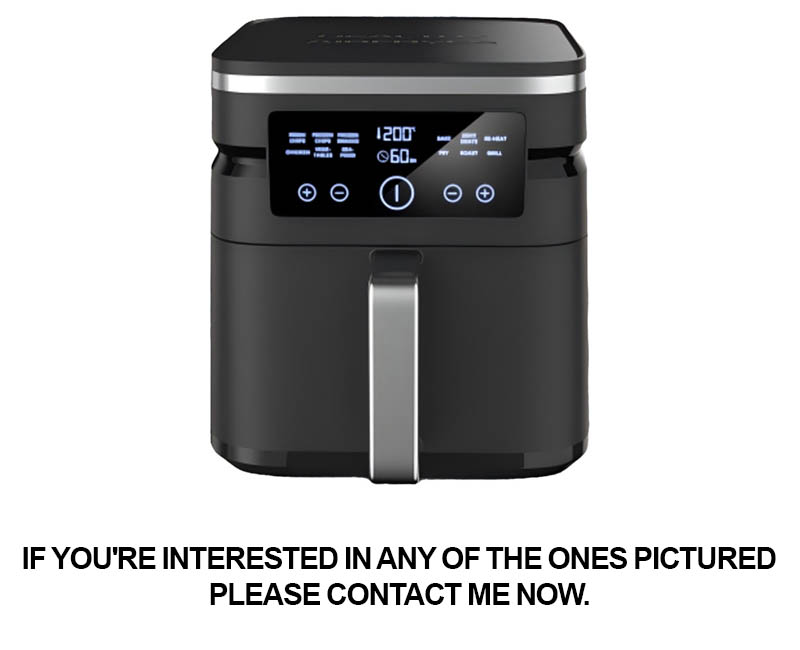

In the ever-evolving world of kitchen appliances, one trend has been particularly captivating: the rise of air fryers. These nifty gadgets have not only transformed the way we cook but have also sparked a wave of innovation in the industry. As we delve into the fascinating journey of air fryers, it’s clear that their popularity is not just a fleeting fad but a testament to the continuous quest for healthier and more convenient cooking methods.

The air fryer, once a niche kitchen gadget, has surged in popularity, becoming a staple in modern households across the globe. This shift from the traditional deep fryer to the healthier, more efficient air fryer is a testament to the evolving demands of consumers who are increasingly health-conscious and environmentally aware.

Once confined to specialty stores and the fringes of culinary culture, air fryers have now made their way into the mainstream. This rise can be attributed to several key factors that have converged to create a perfect storm for the air fryer’s popularity.

Firstly, the health revolution has played a significant role. With the growing awareness of the risks associated with excessive oil consumption and deep-frying, air fryers offer a healthier alternative. They use a fraction of the oil, reducing the calorie count and the risk of heart disease. The ability to enjoy crispy, fried foods without the guilt has made air fryers an attractive option for health-conscious consumers.

Secondly, the convenience factor cannot be overlooked. Air fryers are compact, easy to use, and require minimal clean-up. The ability to cook a variety of foods with little to no oil in a single appliance has made them a time-saver for busy individuals and families. The simple-to-follow recipes and the promise of quick, delicious meals have won over many a kitchen chef.

Thirdly, the technology behind air fryers has advanced significantly. Modern air fryers are equipped with precise temperature controls and timers, allowing for even cooking and ensuring that food is crispy on the outside and tender on the inside. The technology has improved to the point where air fryers can mimic the taste and texture of deep-fried food, which was once thought to be impossible without the oil.

Moreover, the marketing and promotional efforts of manufacturers have been instrumental in the air fryer’s rise. From celebrity endorsements to social media campaigns, the air fryer has become a symbol of modern, healthy living. Influencers and chefs have embraced the technology, showcasing its versatility and highlighting the wide range of dishes that can be prepared using an air fryer.

The affordability of air fryers has also contributed to their popularity. Once a luxury item, air fryers have become more accessible to the average consumer. Prices have dropped significantly, making it easier for people to invest in this kitchen gadget without breaking the bank.

The environmental impact of air fryers is another factor that has gained attention. With concerns over plastic waste and the carbon footprint of food production, air fryers offer a greener alternative. They reduce the need for single-use cooking oil containers and can be used to prepare a variety of meals, thus minimizing food waste.

Additionally, the air fryer’s versatility is a game-changer. It can be used to fry, roast, bake, and even dehydrate food. This multipurpose functionality means that air fryers can replace multiple appliances in a kitchen, saving space and reducing energy consumption.

Lastly, the social aspect of cooking has also played a role in the air fryer’s rise. Air fryers have become a popular choice for hosting gatherings and cooking competitions. The ability to prepare large quantities of food in a healthier way has made them a favorite among those who love to entertain.

In conclusion, the rise of air fryers is a multifaceted phenomenon that reflects the changing landscape of consumer preferences. From health and convenience to technological advancements and environmental concerns, the air fryer has captured the imagination of consumers worldwide, and its popularity shows no signs of slowing down.

The evolution of assembly lines is a testament to human ingenuity and the relentless pursuit of efficiency. It all began with the assembly of simple products, but over time, these lines have become the backbone of modern manufacturing, revolutionizing industries across the globe.

In the early 20th century, the concept of an assembly line was a novel idea. Before then, products were typically made by hand, with each item being crafted individually. However, Henry Ford’s introduction of the moving assembly line for the production of the Model T in 1913 marked a significant turning point. This linear production process allowed for the mass production of cars, drastically reducing the time and labor required to manufacture them.

The initial assembly lines were rudimentary, with workers moving along a line, each adding a specific part to the product. This method, known as the “line flow” process, improved efficiency but was still limited by the speed at which each worker could perform their task. The breakthrough came with the introduction of the conveyor belt, which allowed for a more continuous and streamlined workflow. This innovation, often attributed to Ford’s second engineer, Charles Kettering, further accelerated the pace of production.

As technology advanced, so did the sophistication of assembly lines. The introduction of robotics in the 1960s and 1970s brought about a new era of automation. Robots could perform repetitive tasks with precision and speed, often surpassing the capabilities of human workers. This led to a shift from manual labor to automated assembly, which not only increased productivity but also improved product quality and consistency.

With the advent of computer numerical control (CNC) machines, assembly lines became even more precise and adaptable. CNC machines could program multiple operations into a single machine, reducing the need for manual adjustments and increasing the complexity of products that could be manufactured. This allowed for the production of intricate parts and components, which were previously difficult to produce in large quantities.

The integration of information technology (IT) into assembly lines in the late 20th century brought about a new level of connectivity and intelligence. The use of sensors, software, and databases allowed for real-time monitoring and control of the production process. This enabled manufacturers to predict maintenance needs, optimize production schedules, and respond quickly to changes in demand or supply.

In recent years, the rise of Industry 4.0 has further transformed assembly lines. This fourth industrial revolution is characterized by the interconnectivity of machines, systems, and people through the use of the Internet of Things (IoT). Smart assembly lines can now communicate with each other, share data, and make autonomous decisions, leading to more flexible and responsive production processes.

The evolution of assembly lines has not been without its challenges. The initial automation led to concerns about job displacement and the dehumanization of work. However, over time, new roles have emerged within manufacturing, such as maintenance technicians, software developers, and systems integrators. These new roles require a diverse skill set, including technical knowledge and creative problem-solving abilities.

Today, assembly lines are not just about producing goods; they are about creating value through innovation, efficiency, and sustainability. Companies are increasingly focusing on lean manufacturing principles, which aim to minimize waste and maximize value. This includes the use of just-in-time (JIT) inventory systems, which reduce storage costs and the risk of obsolescence.

In conclusion, the evolution of assembly lines has been a journey of continuous improvement and adaptation. From the simple linear lines of the early 20th century to the sophisticated, intelligent systems of today, assembly lines have become a cornerstone of modern manufacturing. As technology continues to advance, we can expect assembly lines to evolve further, becoming even more efficient, adaptable, and integrated into the broader landscape of global production.

In the realm of kitchen appliances, the advent of the automated air fryer assembly line marks a significant leap in technology and efficiency. This line represents a blend of precision, speed, and innovation, transforming the way we produce one of the most popular cooking appliances on the market.

The heart of the automated air fryer assembly line lies in its sophisticated machinery. Robots and conveyors work in tandem, ensuring each fryer is meticulously assembled with precision. The process begins with raw materials, including plastic components, electrical parts, and heating elements, all of which are carefully sourced for quality and durability.

At the start of the line, automated pick-and-place machines handle the precise placement of parts. These robots, equipped with advanced sensors, can distinguish between different components and place them in the correct sequence. The level of accuracy required here is remarkable, as even a minor misalignment can lead to a defective product.

As the assembly progresses, a series of automated machines take over, each specialized in a specific task. For instance, a robotic arm might secure the heating element, while another station ensures the fryer’s exterior shell is sealed tightly. The integration of these machines allows for a seamless flow of parts through the line.

One of the most innovative aspects of the automated assembly line is the inclusion of vision systems. These systems use cameras to inspect each part and assembly at various stages. They can detect cracks, misalignments, or other defects that the human eye might miss. If a problem is detected, the system can either correct it or divert the part to a rework station, ensuring only perfect products reach the end of the line.

The electrical components are another critical area where automation shines. Soldering robots with precision nozzles apply the correct amount of solder to connect the electrical wires and components. This not only guarantees a reliable connection but also ensures that the soldering process is consistent and efficient.

Once the fryer’s internal components are assembled, the shell is attached. This process involves precise alignment and sealing, which is often done with robotic arms that have been programmed to ensure the perfect fit every time. The use of automated glue applicators and heat sealing machines completes the enclosure, making it water-resistant and ready for the next stage.

The assembly line doesn’t stop at the mechanical and electrical aspects. It also incorporates automated testing stations. Fryers are subjected to various tests, including thermal performance, durability, and safety checks. These tests are crucial for ensuring that the product meets the highest quality standards before it leaves the factory.

After passing all tests, the fryers move to the packaging area. Here, automated systems handle the labeling, boxing, and sealing of the products. The use of barcode scanning and RFID technology ensures that each fryer is accurately tracked and that no errors occur in the packaging process.

The automated air fryer assembly line is not just about speed and efficiency; it’s also about sustainability. By minimizing human intervention, the line reduces waste and energy consumption. The use of recycled materials in the production process and the efficient management of resources further contribute to a greener manufacturing environment.

The impact of this automated assembly line is profound. It has not only increased the speed of production but has also elevated the quality of the air fryers being manufactured. Consumers benefit from a wider variety of features, improved safety, and a product that is more reliable than ever before.

Moreover, the line has opened up new possibilities for customization. With the ability to quickly adapt to new models and features, manufacturers can respond rapidly to market demands and consumer preferences. This agility is a testament to the power of automation in the kitchen appliance industry.

In conclusion, the automated air fryer assembly line is a marvel of modern engineering. It represents a fusion of advanced robotics, precision machinery, and cutting-edge technology. As the line continues to evolve, it’s clear that the future of kitchen appliances will be characterized by even greater efficiency, innovation, and customer satisfaction.

Automation has transformed industries across the globe, bringing a wave of efficiency and innovation. The benefits it offers are numerous and impactful, reshaping how tasks are performed and products are produced. Here’s a closer look at some of the key advantages of automation:

Enhanced ProductivityAutomation significantly boosts productivity by eliminating the need for manual labor in repetitive tasks. Machines can operate 24⁄7 without breaks, leading to a continuous workflow that far exceeds human capabilities. This non-stop operation ensures that production lines run smoothly, leading to higher output and reduced time-to-market for products.

Improved Precision and QualityHuman error is a common issue in manual processes, often leading to defects and inconsistencies. Automation reduces these errors by precisely executing tasks with consistent accuracy. In the case of air fryer assembly lines, automated systems can ensure that each component is correctly placed and the final product meets the highest quality standards.

Cost SavingsWhile the initial investment in automation can be substantial, the long-term cost savings are substantial. Automation reduces labor costs, as fewer workers are needed to perform repetitive tasks. It also minimizes waste due to errors, and the efficiency of automated systems can lead to lower energy consumption, further cutting operational expenses.

Increased SafetyManual labor can be dangerous, especially in environments where there are heavy machinery or hazardous materials. Automation reduces the risk of workplace accidents by removing humans from high-risk tasks. In the context of an air fryer assembly line, automated systems can handle sharp tools and hot surfaces with precision, ensuring a safer working environment.

ScalabilityAutomation systems are designed to be scalable. As demand for products increases, the capacity of an automated assembly line can be expanded without the need for a significant increase in labor. This scalability allows businesses to adapt to market changes quickly and efficiently, without the constraints of hiring and training additional staff.

Continuous ImprovementAutomated systems can be continuously optimized and improved. With the integration of advanced technologies like IoT (Internet of Things) and AI (Artificial Intelligence), assembly lines can be monitored and adjusted in real-time to enhance performance. This ongoing improvement ensures that products are always being produced with the latest technological advancements.

Customization and FlexibilityAutomation allows for greater customization and flexibility in production. For instance, an automated air fryer assembly line can be reprogrammed to produce different models or variations of air fryers with ease. This adaptability is crucial in today’s market, where consumer preferences can change rapidly.

Data-Driven Decision MakingAutomation systems generate vast amounts of data, which can be analyzed to improve processes and make informed decisions. By tracking production metrics, businesses can identify bottlenecks, predict maintenance needs, and make strategic decisions based on real-time data. This data-driven approach leads to more efficient operations and better product development.

Longevity and ReliabilityAutomated systems are designed to last, with components that are engineered for durability and reliability. This means that once an automated assembly line is set up, it can run for years without significant downtime, ensuring a consistent flow of high-quality products.

Environmental ImpactAutomation can contribute to a more sustainable production process. By reducing energy consumption and minimizing waste, automated systems can help businesses reduce their environmental footprint. This is particularly important in the manufacturing of kitchen appliances like air fryers, where energy efficiency is a key selling point.

Employee EmpowermentFinally, automation can empower employees by allowing them to focus on more complex and creative tasks. When mundane tasks are automated, workers can be freed up to engage in higher-value activities, such as problem-solving, innovation, and customer service, which can lead to increased job satisfaction and overall productivity.

In the ever-evolving world of kitchen appliances, air fryers have emerged as a game-changer, blending health-conscious cooking with convenience. The design of these appliances has seen a surge in innovation, offering consumers not just a healthier alternative to deep-frying, but also a plethora of features that enhance the cooking experience. Here are some of the innovative ideas shaping the design of modern air fryers.

Smart Technology Integration: Modern air fryers are no longer just cooking appliances; they are smart devices. With features like Wi-Fi connectivity, users can control their fryers remotely via smartphones or tablets. This integration allows for precise temperature and time adjustments, making it easier to cook a variety of dishes with the perfect texture and flavor.

Programmable Settings: The ability to program settings is a game-changer in air fryer design. Users can set their preferred cooking times and temperatures for different types of food, from crispy French fries to juicy chicken wings. Some models even offer preset programs for specific dishes, ensuring that every meal is cooked to perfection with minimal effort.

Digital Touchscreens: Replacing the traditional knobs and buttons, digital touchscreens have become a standard feature in many air fryers. These screens offer a user-friendly interface, making it easier to navigate through various cooking options and settings. The clear display also allows for quick adjustments and easy monitoring of the cooking process.

Variable Heat Settings: One of the key innovations in air fryer design is the ability to adjust heat settings. While most air fryers operate at a high temperature to achieve the desired crispiness, some models now offer a range of heat settings. This allows for a more nuanced cooking experience, enabling users to gently defrost or reheat delicate foods without overcooking them.

Non-Stick Coatings: The interior of air fryers has seen significant improvements with the use of advanced non-stick coatings. These coatings not only make cleanup easier but also reduce the risk of food sticking, ensuring that every dish is released effortlessly. Some brands have even developed coatings that are more durable and longer-lasting than traditional non-stick surfaces.

Eco-Friendly and Energy-Efficient: Innovators in air fryer design are increasingly focusing on sustainability. New models are being engineered to be more energy-efficient, using less power than traditional ovens or deep fryers. This not only saves on energy bills but also contributes to a greener planet.

Safety Features: Modern air fryers come with a variety of safety features to prevent accidents and protect the user. These include automatic shut-off functions that activate when the fryer is left unattended or when the cooking time has elapsed. Some models also have cool-touch handles and bases to prevent burns.

Versatile Accessories: To expand the capabilities of air fryers, manufacturers are offering a range of accessories. These include oven-safe baskets, grill inserts, and even dehydrator trays. These accessories allow users to prepare a wider array of dishes, from crispy vegetables to homemade jerky.

Design and Aesthetics: Design has become an important aspect of air fryer innovation. Modern models come in sleek, stylish designs that complement kitchen decor. The compact size and minimalist look of many new air fryers make them not just functional but also visually appealing.

Healthy Cooking Options: Perhaps the most innovative aspect of air fryer design is the emphasis on health. These appliances enable users to enjoy the same delicious flavors as deep-fried foods but with significantly less oil. This not only reduces calorie intake but also minimizes the risk of heart disease and other health issues associated with fried foods.

The continuous innovation in air fryer design reflects a deep understanding of consumer needs and preferences. As technology advances, we can expect to see even more creative and efficient cooking solutions that make healthy living easier and more enjoyable.

In the dynamic landscape of kitchen appliances, the industry is witnessing a surge in technological advancements and consumer preferences. Let’s delve into some of the key trends and data analysis shaping the future of the market.

Smart IntegrationOne of the most prominent trends is the integration of smart technology into kitchen appliances. Air fryers, for instance, are now equipped with smart features like Bluetooth connectivity, allowing users to control them remotely via their smartphones. This trend is not just about convenience; it’s about creating a seamless kitchen experience that blends the ease of modern technology with traditional cooking methods.

Energy EfficiencyEnergy consumption is a significant concern for consumers and manufacturers alike. The latest data shows a growing preference for energy-efficient appliances, including air fryers. These appliances are designed not only to cook food with minimal oil but also to use less electricity than conventional cooking methods. The trend towards energy-saving features is expected to continue, driven by environmental consciousness and cost-saving benefits.

Health and WellnessAs people become more health-conscious, the demand for healthier cooking options is on the rise. Air fryers have become a symbol of this movement, offering a healthier alternative to deep-frying. The industry is responding by developing air fryers that can cook a wider variety of foods, from crispy potatoes to juicy chicken, all while maintaining a lower fat content. Data indicates that consumers are not just looking for healthier options but also for appliances that make these healthier choices more accessible and convenient.

Customization and PersonalizationModern consumers seek products that cater to their unique needs and preferences. Air fryer manufacturers are responding by offering a range of models with customizable settings. From adjustable temperature controls to pre-programmed recipes, these air fryers allow users to tailor their cooking experience. The data reflects a shift in consumer behavior, with a preference for appliances that offer greater control and flexibility.

SustainabilitySustainability is becoming a crucial factor in product development. Appliances that are designed with the environment in mind, such as those made from recycled materials or with a longer lifespan, are gaining traction. The air fryer industry is not immune to this trend, with some manufacturers focusing on creating eco-friendly products that are durable and repairable.

E-commerce and Direct-to-Consumer SalesThe rise of e-commerce has changed the way consumers purchase kitchen appliances. Data shows that an increasing number of consumers are buying air fryers and other kitchen gadgets online, with direct-to-consumer sales becoming more prevalent. This shift is attributed to the convenience of online shopping and the competitive pricing that e-commerce platforms often offer.

Global Market ExpansionThe air fryer market is no longer confined to certain regions. It’s expanding globally, with emerging markets showing significant growth. Data from various market research reports indicates that countries with a growing middle class and a rising awareness of healthier eating habits are driving this expansion. Manufacturers are adapting their strategies to cater to these diverse markets, considering local preferences and cultural differences.

Marketing and BrandingThe way kitchen appliance brands market their products is also evolving. Social media and influencer partnerships play a significant role in product promotion. Data from consumer engagement studies shows that consumers are more likely to be influenced by peer recommendations and social proof. Brands are investing in content marketing and interactive campaigns to connect with their audience and build brand loyalty.

Technological IntegrationTechnological integration is not limited to smart features; it also extends to the cooking process itself. Air fryers are now equipped with advanced heating elements and sensors that ensure even cooking and precise temperature control. The data indicates that these technological advancements are a key factor in the appeal of modern air fryers, as they offer a more consistent and efficient cooking experience.

In conclusion, the air fryer industry is undergoing a transformation driven by technological innovation, consumer demand, and global market dynamics. From smart integration and energy efficiency to sustainability and marketing strategies, the industry is poised for continued growth as it adapts to the evolving landscape of kitchen appliances.

The air fryer has revolutionized the way we cook, offering a healthier alternative to traditional frying methods. As technology advances, the future of air fryers looks promising, with several innovative features and trends shaping the industry. Here’s a glimpse into what the future might hold for air fryers:

Enhanced Health BenefitsAir fryers are already known for their ability to cook food with less oil, reducing the calorie count and fat content. In the future, we can expect these appliances to incorporate even more health-conscious features. Imagine air fryers that not only reduce oil but also remove harmful trans fats, or even have the capability to sterilize food, eliminating bacteria and pathogens.

Smart Technology IntegrationThe rise of smart home technology has paved the way for kitchen appliances to become more connected. Future air fryers could be equipped with IoT capabilities, allowing users to control their appliances remotely through smartphones or voice assistants. This could include features like automatic cooking programs based on dietary preferences, or even predictive maintenance to alert users of potential issues before they arise.

Customizable Cooking ProfilesOne of the limitations of current air fryers is their fixed cooking settings. The future might bring air fryers with customizable cooking profiles, where users can input specific details such as the type of food, desired crispiness, and even the desired nutritional content. This would allow for a more personalized cooking experience, catering to individual tastes and health needs.

Energy EfficiencyAs sustainability becomes a growing concern, future air fryers are likely to be more energy-efficient. Innovations could include better insulation, more efficient heating elements, and intelligent power management systems that adjust energy use based on the cooking process. This not only saves money on energy bills but also reduces the environmental impact.

Compact and Modular DesignsSpace is often a premium in modern kitchens, and future air fryers might come in more compact, space-saving designs. Additionally, modular designs could allow users to expand their cooking capabilities. For example, a base unit could be paired with various attachments for grilling, roasting, or even baking, making the air fryer a versatile kitchen centerpiece.

Advanced Cooking TechniquesThe future of air fryers may see the integration of advanced cooking techniques that go beyond the traditional air frying method. Imagine an air fryer that can simulate sous-vide cooking for precise temperature control, or even incorporate steam functions for a more diverse range of dishes. These advancements would open up new culinary possibilities for users.

Eco-Friendly MaterialsAs consumers become more environmentally conscious, the materials used in air fryer manufacturing will likely evolve. We could see a shift towards sustainable materials, such as recycled plastics and biodegradable components, reducing the carbon footprint of these appliances.

Personalized Nutrition and Health TrackingIn the future, air fryers might not just cook food but also provide nutritional insights. With the help of sensors and AI, these appliances could analyze the nutritional content of the food being cooked and offer dietary recommendations or track the user’s nutritional intake over time.

Enhanced Safety FeaturesSafety is always a top priority, and future air fryers are expected to come with improved safety features. This could include automatic shut-off functions, child locks, and smart sensors that detect overcooking or food spoilage, ensuring a safer cooking environment.

Global Market ExpansionAs the popularity of air fryers continues to grow, we can anticipate a global market expansion. New designs and features tailored to different cultural preferences and cooking styles will emerge, making air fryers a staple in kitchens worldwide.

The future of air fryers is bright, with a focus on health, technology, sustainability, and convenience. As these appliances continue to evolve, they will undoubtedly play a significant role in shaping the culinary landscape of the future.

In the world of kitchen appliances, there are numerous success stories that showcase the ingenuity and adaptability of companies in the face of changing consumer demands and technological advancements. Here are a few case studies that highlight the triumphs in the air fryer industry:

1. The Emergence of a New Market LeaderOne such story is the rise of a relatively new brand that entered the air fryer market with a unique design and a focus on health-conscious consumers. By leveraging the latest materials and smart technology, this company managed to carve out a niche for itself. Their air fryers were not only efficient and easy to use but also came with health benefits, such as reduced oil usage and healthier cooking options. The brand’s commitment to innovation and customer satisfaction led to a rapid increase in market share and a loyal customer base.

2. The Revival of a Legacy BrandA well-established kitchen appliance manufacturer faced the challenge of staying relevant in a market dominated by trendy new startups. They turned to their roots and reimagined their iconic brand with a modern twist. By integrating advanced features like app connectivity and customizable cooking programs, they managed to attract both new customers and long-time supporters. The brand’s ability to evolve and incorporate the latest technology into their classic designs was a key factor in their resurgence.

3. The Power of Collaborative InnovationA small startup found success by partnering with a leading technology company. This collaboration resulted in the development of an air fryer that combined the latest in smart home technology with the convenience of air frying. The product was not just a kitchen gadget but a gateway to a connected cooking experience. The success of this partnership was a testament to the power of combining domain expertise with cutting-edge technology.

4. The Global Expansion of a Local HitA local air fryer brand gained popularity for its unique design and affordable pricing. They leveraged social media and influencer partnerships to create a buzz around their product. As word spread, the brand expanded globally, adapting their marketing strategies to different cultures and markets. Their ability to maintain their brand identity while embracing local preferences was crucial to their international success.

5. The Sustainability StoryAn air fryer manufacturer faced the challenge of reducing their environmental footprint. They invested in research and development to create a range of air fryers made from recycled materials and designed for longevity. Their commitment to sustainability resonated with eco-conscious consumers, and the brand became synonymous with eco-friendly kitchen appliances. This case study shows how a focus on sustainability can be a powerful differentiator in the market.

6. The Power of PersonalizationA company specializing in air fryers introduced a line that allowed customers to customize their cooking experience. With options for different cooking temperatures, times, and even the ability to add their own recipes, the product appealed to tech-savvy consumers who value personalization. The company’s success lies in their understanding of the modern consumer’s desire for control and customization in their kitchen appliances.

7. The Impact of Retail PartnershipsOne air fryer brand achieved significant growth by partnering with major retailers. By ensuring their products were prominently displayed and easily accessible, they made it convenient for customers to try and buy their products. The strategic placement of their air fryers in retail stores played a crucial role in their market penetration and sales success.

These case studies and success stories demonstrate the diverse paths to success in the air fryer industry. From innovation in design to strategic partnerships, these brands have shown that with the right approach, even a small or new player can make a big impact in the competitive kitchen appliance market.

In the ever-evolving landscape of technology and consumer demand, the narrative of success is often intertwined with innovation and adaptation. As we reflect on the case studies and success stories that have shaped industries, it’s clear that a blend of strategic thinking, relentless pursuit of excellence, and a keen understanding of market needs has been the driving force behind these triumphs. From groundbreaking products to transformative business models, these stories offer valuable lessons and insights into what it takes to thrive in a competitive world.

In the realm of technology, one such story is that of the company that revolutionized the way we communicate. Starting with a simple idea, they developed a device that would change the way we interact with one another. The journey was fraught with challenges, but their unwavering commitment to quality and customer satisfaction paid off. Today, their product is a staple in millions of homes, a testament to the power of a vision and the perseverance to see it through.

In the world of consumer goods, a different narrative unfolds. A brand that once struggled to gain traction in a crowded market managed to carve out a niche for itself by focusing on sustainability and ethical sourcing. Their commitment to these principles resonated with consumers who sought out products that aligned with their values. Through smart marketing and a strong social media presence, they not only grew their customer base but also became a leader in their industry.

The healthcare sector has also seen its fair share of success stories. A small startup, with a novel approach to medical diagnostics, caught the attention of investors and healthcare professionals alike. Their innovative technology, which offered faster and more accurate results, quickly gained traction. The company’s ability to pivot and adapt to regulatory changes and market demands allowed them to scale their operations and become a key player in the industry.

In the realm of finance, a story of resilience and innovation stands out. A financial institution that faced significant challenges during the global financial crisis managed to turn things around by embracing technology and reimagining their business model. They invested in digital banking solutions, making financial services more accessible and user-friendly. This shift not only saved the company but also positioned it as a leader in the digital banking space.

The success stories in the tech industry are often about pushing boundaries and creating entirely new markets. A company that started as a small software developer has grown into a global giant, changing the way we work, communicate, and live. Their relentless pursuit of innovation, coupled with a culture that fosters creativity and collaboration, has allowed them to stay ahead of the curve.

In the food industry, a brand that focused on health and wellness has become a household name. Their commitment to organic and natural ingredients, combined with a unique approach to product development, has captured the attention of health-conscious consumers. Through strategic partnerships and a strong online presence, they have expanded their reach and solidified their position as a leader in the health food market.

In the retail sector, a story of agility and customer-centricity is particularly inspiring. A retailer that faced stiff competition from online giants managed to thrive by focusing on the unique shopping experience they could offer. By investing in store design, customer service, and exclusive products, they created a destination for shoppers looking for more than just a transaction. Their success lies in understanding that the physical store can still be a powerful tool in the retail landscape.

As we delve into these stories, one common thread emerges: the importance of adaptability. Whether it’s embracing new technologies, listening to customer feedback, or navigating regulatory changes, the ability to adapt is crucial for long-term success. These companies didn’t just survive; they thrived by staying ahead of the curve and being willing to make bold moves.

In conclusion, the case studies and success stories we’ve explored are not just tales of triumph. They are lessons in resilience, innovation, and the power of a clear vision. They remind us that success is not a one-size-fits-all concept but rather a series of choices and actions that lead to positive outcomes. By studying these stories, we can gain insights into what it takes to build a successful business and apply those lessons to our own endeavors.