The Arctic Grade Waffle Maker stands proud as a revolutionary kitchen equipment for intense cold environments, providing robust bloodless resistance and revolutionary layout. Engineered with specialised materials and insulation, it operates reliably at temperatures as little as -forty°C, making sure secure and delicious waffle-making even inside the most harsh climates. Its short heating, automatic close-off, and consumer-friendly capabilities make it an ideal preference for out of doors fans and bloodless region citizens. The Arctic Grade Waffle Maker’s versatility and dedication to safety and quality have earned it huge market recognition among those looking for reliable kitchen appliances for severe cold conditions.

The OEM kitchen appliance manufacturing industry is experiencing fast growth due to various client needs. OEM producers play a important position in providing custom designed equipment solutions, with the enterprise’s business chain which include raw cloth providers, OEM manufacturers, emblem producers, and channel income. Key product kinds are cooking, cleaning, and storage structures. The industry in China benefits from sturdy production competencies and a complete deliver chain, attracting international manufacturers. market opposition is fierce, with OEM manufacturers focusing on design, technological, and fabric innovation to enhance product pleasant and enchantment. As marketplace trends shift toward environmental sustainability and clever generation, OEM manufacturers are embracing opportunities to expand strength-efficient and shrewd kitchen appliances, while also imparting personalized and move-enterprise solutions.

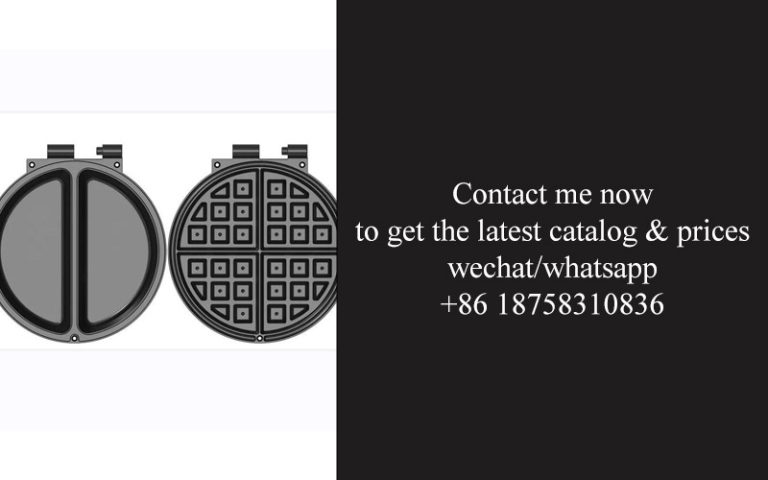

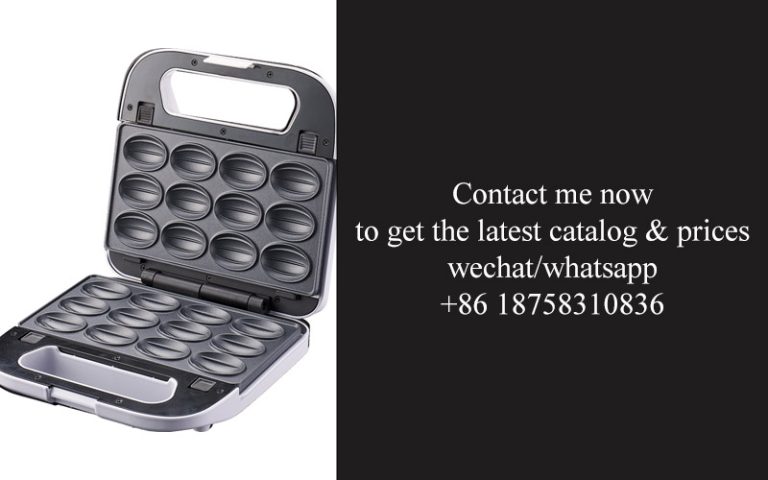

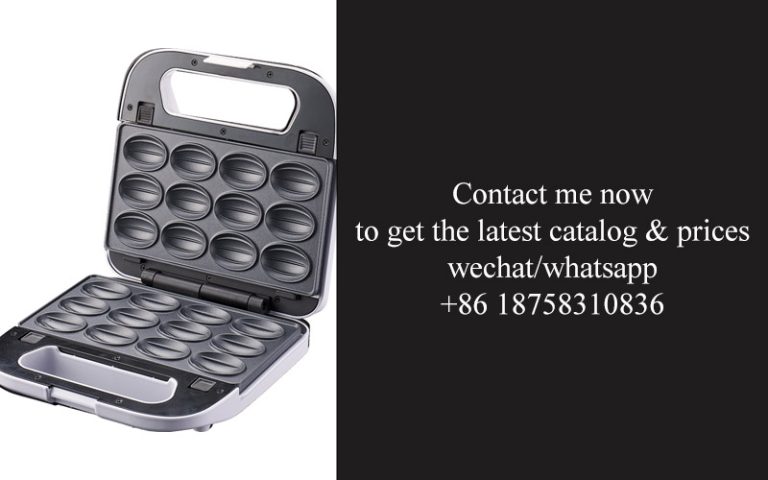

in the pursuit of innovation, commercial waffle maker factories are riding market boom with their smart, power-green waffle irons. these machines, now geared up with smart control systems and multifunctional abilities, cater to diverse town eating desires. regardless of competition, factories are expanding their product traces with innovative shapes and designs, even as specializing in sustainability and consumer-pleasant functions. As demand for convenience and customization rises, the industrial waffle maker manufacturing unit remains a key participant in the evolving enterprise.

The Ningbo small equipment supplier has correctly reached a monthly income milestone of 10,000 devices, thanks to its modern designs and marketplace-driven method. that specialize in contemporary aesthetics, clever generation integration, and user-friendly capabilities, Ningbo’s kitchen appliances cater to the growing call for for intelligent, power-green, and

products. by using constantly innovating and offering personalised answers, the provider has secured a leading function in the aggressive appliance market.

The East Coast OEM manufacturing unit stands out in the kitchen equipment enterprise with its revolutionary technique and bendy customization. With a minimum order amount of 500 devices, the factory efficiently meets various marketplace needs, catering to both small and massive-scale clients. Their advanced generation and enterprise knowledge make certain , wise, and electricity-efficient kitchen home equipment. through integrating clever features, supplying customized designs, and adopting modular production, the East Coast OEM manufacturing unit leads the industry in performance and innovation.

The CE-certified air fryer OEM marketplace is thriving as clients are seeking for more healthy cooking alternatives. manufacturers, dealing with excessive opposition and strict regulatory requirements like CE Certification, are specializing in product protection, environmental friendliness, and innovation. Integrating smart capabilities and catering to various patron desires thru personalized designs are key techniques. ensuring compliance with CE Certification no longer only guarantees marketplace get entry to but additionally complements logo credibility and consumer accept as true with.

The EAC compliant sandwich maker factory performs a important position inside the appliance marketplace, making sure protection and fine with its products. As a kitchen staple, the sandwich maker is a need to-have for sure cooking reviews. by way of adhering to EAC standards, those factories assure that their sandwich makers meet rigorous safety and environmental rules, enhancing patron confidence and brand popularity. through innovative designs and smart functions, those home equipment cater to a numerous range of cooking needs, making them a positive preference for each domestic and business use.

in the kitchen appliance marketplace, air fryers have soared in recognition because of their healthful and convenient functions, making low MOQ air fryer manufacturers the new favorites. those producers cater to diverse client wishes with a variety of capacities and functionalities, adapting quickly to marketplace comments. They gain from a competitive part through allowing small groups and startups to enter the market with decrease boundaries, riding innovation and fee-effectiveness. The upward thrust of on line sales channels has increased their marketplace reach, while a focus on

materials and clever technology complements their appeal. facts-driven techniques, such as consumer remarks and sales analytics, further bolster their competitive benefits, solidifying their function within the marketplace.

The customizable touch grill OEM fashion has considerably driven a 30% value reduction in the appliance enterprise. by using optimizing product design, decreasing stock congestion, and streamlining supply chains, those OEMs enhance procurement performance and universal production costs. Technological improvements, which include automation and clever production, further make a contribution to this cost financial savings, even as additionally enhancing product exceptional and marketplace competitiveness. This modern approach not most effective blessings manufacturers however also guarantees clients obtain , customized appliances at a greater low cost price.

The upward push of the “wholesome living” idea has spurred growth in the kitchen equipment industry, especially for high-extent juicer manufacturing. corporations inside the metropolis are embracing strategies to enhance production efficiency, inclusive of deploying automated lines, optimizing manufacturing approaches, and implementing JIT stock control. To keep competitiveness, those businesses are striving to gain a forty eight-hour quoting reaction, which calls for streamlined inner conversation, strong records management structures, and near provider collaboration. This short turnaround not handiest boosts purchaser delight but additionally underscores the importance of data-driven product innovation, specializing in smart, fitness-conscious, and power-green home equipment, at the same time as catering to personalized purchaser desires.