Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In recent years, the kitchen has become more than just a place for cooking; it’s a hub for innovation and health-conscious living. Among the myriad of advancements, ceramic coated non-stick plates have emerged as a game-changer, offering consumers a blend of convenience, durability, and eco-friendliness. This shift has been driven by not only changing consumer preferences but also by the evolving manufacturing processes that have made these cookware pieces more accessible and desirable. Let’s delve into the journey of ceramic coated non-stick plates and the impact they’ve made on the culinary world.

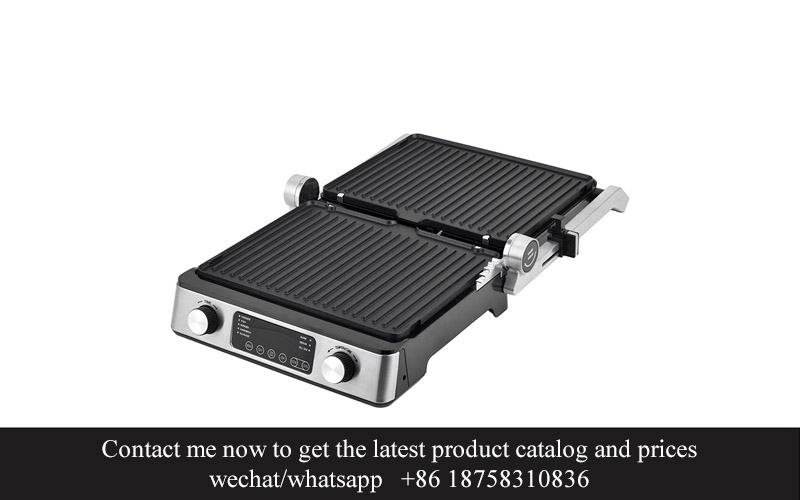

Ceramic coated non-stick plates have become a staple in modern kitchens, offering a healthier, more durable, and easier-to-clean alternative to traditional non-stick cookware. These innovative plates are not just a passing trend; they represent a significant leap forward in kitchen technology. Let’s dive into the world of ceramic coated non-stick plates and understand what makes them so special.

The ceramic coating is a thin, non-reactive layer that is applied to the surface of the plate. It’s this coating that gives the plate its non-stick properties, making it a favorite among chefs and home cooks alike. Unlike traditional non-stick coatings, which often contain potentially harmful chemicals like PFOA and PTFE, ceramic coatings are free from these substances, providing a safer cooking experience.

When you slide a spatula under a dish cooked on a ceramic coated non-stick plate, you’ll notice how effortlessly the food releases from the surface. This is due to the unique properties of the ceramic material, which creates a smooth, non-porous surface that prevents food from sticking. It’s this same quality that makes cleaning these plates a breeze. Just a quick wipe with a damp cloth is often all that’s needed to keep them looking like new.

But the benefits of ceramic coated non-stick plates don’t stop there. They are also known for their exceptional durability. The ceramic coating is highly resistant to scratches and wear, which means your plate can withstand the rigors of everyday cooking without losing its non-stick properties. This longevity is a significant advantage over traditional non-stick cookware, which can degrade over time and lose its effectiveness.

In the kitchen, we’re always looking for ways to cook healthier meals, and ceramic coated non-stick plates help us do just that. The non-stick nature of these plates means you can cook with less oil, reducing the calorie and fat content of your dishes. This is particularly beneficial for those following a heart-healthy diet or looking to reduce their overall fat intake.

The process of manufacturing ceramic coated non-stick plates is a testament to modern innovation. Factories specializing in these plates use advanced techniques to apply the ceramic coating, ensuring a high-quality finish that lasts. The manufacturing process involves several steps, each carefully controlled to produce a plate that meets the highest standards of performance and safety.

From the selection of raw materials to the final quality control checks, every aspect of the production process is designed to create a product that stands out in the market. The use of high-quality ceramics and the latest technology in coating application ensures that each plate is not only non-stick but also scratch-resistant and durable.

In recent years, the market for ceramic coated non-stick plates has seen a surge in popularity. Consumers are increasingly seeking out cookware that is not only functional but also environmentally friendly and safe for their families. The demand for these plates has been driven by a combination of factors, including health concerns, the desire for long-lasting cookware, and the growing awareness of the environmental impact of traditional non-stick coatings.

As the market continues to evolve, so too do the products. Manufacturers are constantly looking for ways to improve the performance and aesthetics of their ceramic coated non-stick plates. This includes exploring new materials and coatings that offer even better non-stick properties, increased durability, and enhanced ease of cleaning.

The global demand for ceramic coated non-stick plates is on the rise, with markets in Europe and North America leading the charge. As more consumers become aware of the benefits these plates offer, we can expect to see continued growth in this segment of the kitchenware industry.

Despite the many advantages of ceramic coated non-stick plates, the industry faces its own set of challenges. One of the biggest is the cost of production. High-quality ceramics and advanced manufacturing processes can be expensive, which can make the final product more costly than traditional non-stick cookware. However, many consumers are willing to pay a premium for the health, safety, and convenience that ceramic coated plates provide.

As we look to the future, the ceramic coated non-stick plate industry is poised for continued growth. With advancements in manufacturing technology and an increasing consumer demand for healthier, more durable cookware, these plates are set to become an even more integral part of modern kitchens around the world.

Ceramic coated non-stick plates have quietly but surely become a favorite in kitchen drawers worldwide. This rise in popularity is a testament to the evolving demands of modern consumers who seek healthier, more durable, and environmentally friendly kitchenware options. The shift towards ceramic coatings reflects a broader trend in the kitchenware industry, where innovation and functionality are at the forefront.

Once dominated by traditional non-stick coatings, such as Teflon, the market has seen a surge in the adoption of ceramic coatings. These coatings are not only free from harmful chemicals like PFOA and PTFE, which have raised health concerns, but they also offer a more sustainable alternative. The eco-conscious consumer, increasingly aware of the impact of their purchases, has been a significant driver behind this shift.

The performance of ceramic coatings has also played a crucial role in their popularity. They are renowned for their exceptional non-stick properties, which make cooking a breeze without the need for excessive oil or butter. This not only simplifies the cooking process but also enhances the flavor of the food, as less fat means a purer taste. The durability of ceramic coatings is another factor that has won over many cooks. They are more resistant to scratches and wear compared to their traditional counterparts, ensuring that the plate remains effective and attractive for years.

As the kitchenware market has expanded, so too has the demand for a variety of cookware. Ceramic coated non-stick plates have found their way into diverse culinary styles and preferences. From the minimalist design of modern kitchens to the rustic charm of farmhouse styles, these plates have become a versatile choice. Their sleek appearance and ease of maintenance have made them a favorite among busy professionals and culinary enthusiasts alike.

Another factor contributing to the rise of ceramic coated non-stick plates is the increased awareness of health and wellness. With more people looking for alternatives to non-stick cookware that may leach harmful substances into food, ceramic coatings offer a safer option. The smooth, non-porous surface of ceramic coatings reduces the risk of food particles getting trapped and potentially spoiling, which can be a concern with other types of cookware.

The industry has also seen advancements in the technology used to apply ceramic coatings. Modern factories employ advanced techniques to ensure a uniform and high-quality finish, which is essential for the longevity of the product. These improvements have not only enhanced the performance of ceramic coated non-stick plates but have also led to a wider range of designs and colors, catering to individual tastes and kitchen aesthetics.

Retailers have also played a significant role in the promotion of ceramic coated non-stick plates. By educating consumers about the benefits of these products, they have helped to build trust and credibility. Additionally, the competitive pricing of ceramic coated options has made them an affordable choice for those looking to upgrade their kitchenware without breaking the bank.

The global kitchenware market has been witnessing a shift towards premium and healthier products, and ceramic coated non-stick plates have been at the forefront of this movement. As consumers become more health-conscious and environmentally aware, the demand for these plates is expected to grow further. The industry has responded by investing in research and development to innovate and improve upon existing technologies.

The rise of ceramic coated non-stick plates is not just a trend; it’s a reflection of the evolving values and needs of consumers. As the kitchenware industry continues to evolve, ceramic coatings are likely to play an increasingly significant role, offering a sustainable, healthful, and functional solution for cooking enthusiasts everywhere.

Ceramic coated non-stick plates have surged in popularity, and for good reason. Here are some of the key benefits that have made them a kitchen staple.

Their Healthier Cooking ExperienceCeramic coatings are non-toxic and free from harmful chemicals like PFOA and PTFE, which are often found in traditional non-stick coatings. This means you can cook with peace of mind, knowing that your food is not being exposed to potentially harmful substances. The natural, ceramic-based coatings provide a healthier cooking environment, making them a favorite among health-conscious consumers.

Longevity and DurabilityCompared to traditional non-stick surfaces, ceramic coatings are significantly more durable. They are resistant to scratching, peeling, and fading, which means your plates will maintain their non-stick properties for much longer. This durability also means fewer replacements and a more cost-effective cooking experience over time.

Ease of CleaningOne of the most appealing aspects of ceramic coated non-stick plates is their ease of cleaning. The smooth, non-stick surface means that food particles don’t stick, making it simple to wipe away spills or wash the plate with minimal effort. This not only saves time but also reduces the need for harsh cleaning agents, which can be damaging to the environment.

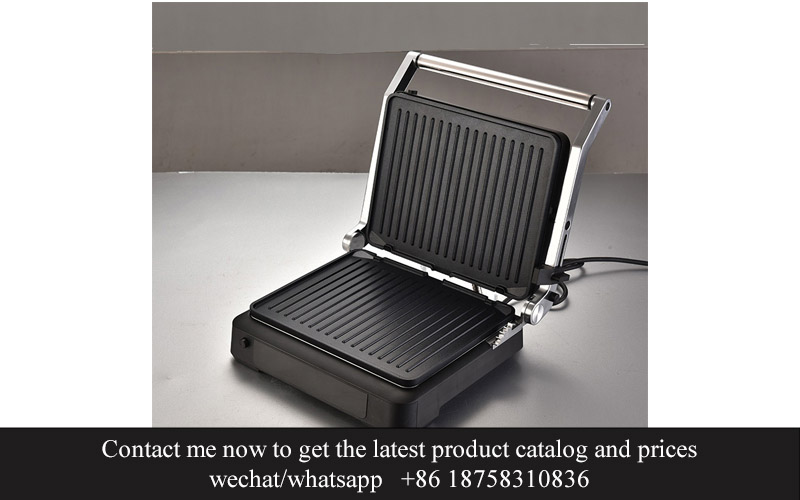

Versatility in CookingCeramic coated non-stick plates are incredibly versatile. They can be used on induction cooktops, gas stoves, and even in the oven, up to temperatures of 450°F (232°C). This versatility allows for a wide range of cooking techniques, from searing and sautéing to baking and roasting, without the risk of food sticking or burning.

Enhanced Flavor PreservationBecause ceramic coatings don’t require the use of butter or oil to prevent sticking, they help to preserve the natural flavors of the food. This means you can enjoy the true taste of your ingredients without the interference of added fats or chemicals, leading to a more authentic and enjoyable dining experience.

Heat ResistanceCeramic coatings are highly resistant to heat, which is particularly beneficial for those who like to sear meats or use hot pans. The plates can withstand high temperatures without warping or releasing harmful fumes, ensuring that your cooking is both safe and effective.

Environmentally FriendlyThe non-toxic nature of ceramic coatings makes them a more environmentally friendly option. They are free from the persistent organic pollutants (POPs) that can be found in conventional non-stick coatings, reducing the risk of contamination of soil and water sources. Additionally, the longevity of ceramic coated non-stick plates means fewer products end up in landfills.

Safe for All Types of CookwareCeramic coated non-stick plates can be used with metal utensils without the risk of damaging the surface. This means you can enjoy the convenience of non-stick cooking without the worry of scratching or damaging the plates, as you might with traditional non-stick coatings.

Improved Cooking PerformanceThe smooth, even surface of ceramic coatings ensures that heat is distributed more evenly across the plate. This leads to more consistent cooking results and helps prevent hot spots, which can cause food to burn or cook unevenly.

Enhanced Cooking ExperienceThe combination of health, durability, ease of use, and versatility makes ceramic coated non-stick plates an excellent choice for any kitchen. They offer a superior cooking experience that is not only convenient but also enjoyable, allowing you to focus on the culinary aspect of cooking rather than the hassle of food sticking to your cookware.

Ceramic coated non-stick plates have become a staple in modern kitchens, and the factories that produce them play a pivotal role in this culinary revolution. These factories are the heart of innovation, efficiency, and quality control, ensuring that the end product meets the high standards expected by consumers. Here’s a closer look at the multifaceted role these factories play:

In the heart of these factories, skilled workers meticulously craft each plate, starting with high-quality aluminum or stainless steel substrates. These materials are chosen for their durability and heat conductivity, which are essential for the performance of ceramic coated non-stick plates. The manufacturing process begins with a thorough cleaning and preparation of the base material to ensure a seamless coating application.

The coating itself is a complex blend of ceramic particles and binders, which are applied using advanced techniques such as plasma spray or electrostatic powder coating. These methods provide a uniform and durable layer that adheres tightly to the substrate, creating a non-stick surface that’s resistant to wear and tear. The factories invest heavily in research and development to perfect the coating formula, often testing various combinations of ceramics and binders to achieve the best balance of non-stick properties and longevity.

Quality control is paramount in these factories, with stringent checks at every stage of production. Inspectors use high-resolution cameras and other cutting-edge tools to detect any imperfections or inconsistencies in the coating. This ensures that only the highest quality plates leave the factory, reducing the risk of defects and customer dissatisfaction.

As the demand for ceramic coated non-stick plates continues to grow, these factories must also adapt to changing market trends. They often introduce new designs and features to cater to consumer preferences, such as colored coatings, different sizes, and integrated accessories like steamers or colanders. This requires a flexible production line that can switch between various products quickly and efficiently.

The environmental impact of manufacturing processes is also a significant consideration for these factories. Many have invested in eco-friendly practices, such as using recycled materials, minimizing waste, and reducing energy consumption. These sustainable initiatives not only benefit the planet but also appeal to environmentally conscious consumers who are increasingly seeking eco-friendly kitchenware options.

Moreover, these factories often serve as hubs for innovation, collaborating with chefs, kitchen designers, and even food scientists to develop new and improved products. For example, they might work on enhancing the non-stick properties to make them even more resistant to scratching or to create plates that can withstand higher temperatures without releasing harmful chemicals.

The logistics of distribution are another critical aspect of these factories’ operations. They must manage inventory, coordinate shipping, and ensure that products reach retailers and customers in a timely manner. This involves complex supply chain management and often requires partnerships with shipping companies and logistics providers to guarantee efficient delivery.

In the realm of global trade, these factories also navigate the complexities of international regulations and tariffs. They must comply with various standards and certifications required by different countries, which can be a challenging but necessary part of the export process. This international reach not only expands their market but also fosters cultural exchange and understanding.

Lastly, the factories are at the forefront of workforce development. They provide training and education for their employees, ensuring that they have the skills and knowledge to produce the highest quality products. This investment in human capital is crucial for maintaining a competitive edge in a rapidly evolving industry.

In summary, ceramic coated non-stick plate factories are not just manufacturing facilities; they are centers of technological advancement, quality assurance, and innovation. They are where the magic happens, turning raw materials into the everyday kitchen essentials that make cooking easier, healthier, and more enjoyable for millions of people around the world.

In the realm of kitchenware, the evolution of ceramic coated non-stick plates has been marked by remarkable innovations in the manufacturing process. These advancements have not only enhanced the quality and performance of the products but have also contributed to their growing popularity among consumers. Here’s a closer look at some of the key innovations shaping the landscape of non-stick plate manufacturing:

The shift from traditional non-stick coatings to ceramic has been a game-changer. Unlike older coatings like Teflon, which can release harmful fumes at high temperatures, ceramic coatings are free from PFOA and PTFE, making them a healthier choice for cooking enthusiasts. The development of these eco-friendly coatings has been a significant milestone in the industry.

Precision in Coating ApplicationOne of the most notable innovations is the refinement of the coating application process. Modern factories have adopted robotic systems that precisely spray the ceramic coating onto the plate surface. This method ensures a uniform and even layer, which is crucial for the non-stick properties. The precision also extends to the thickness of the coating, preventing flaking and extending the lifespan of the product.

Enhanced Durability Through High-Temperature TreatmentCeramic coated non-stick plates are known for their durability, and this is largely due to a high-temperature treatment process. After the coating is applied, the plates are subjected to extreme heat, which fuses the ceramic particles into a hard, scratch-resistant layer. This treatment not only improves the longevity of the product but also ensures that the non-stick properties remain intact even after years of use.

Incorporation of NanotechnologyNanotechnology has revolutionized the manufacturing of ceramic coated non-stick plates. By using nanoparticles, manufacturers can create a coating that is even more durable and non-reactive. These tiny particles fill in any gaps or pores in the ceramic surface, creating a seamless and robust barrier that resists scratches and wear. This technology has pushed the boundaries of what is possible in non-stick cookware.

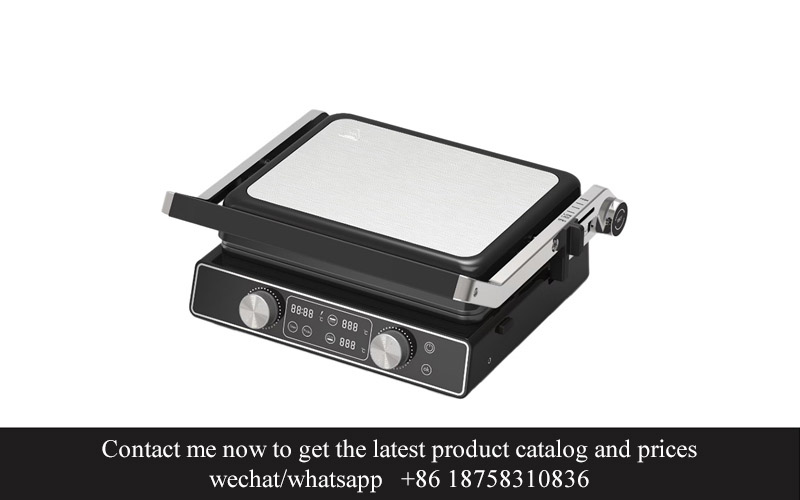

Customization and AestheticsThe manufacturing process has also evolved to include customization options. Consumers today not only look for functionality but also for aesthetically pleasing products. Factories now offer a variety of colors, patterns, and finishes, allowing customers to choose plates that complement their kitchen decor. This level of personalization was not feasible with older manufacturing techniques.

Energy-Efficient Production TechniquesAs environmental concerns grow, so does the need for energy-efficient production techniques. Ceramic coated non-stick plate factories have invested in energy-saving technologies that reduce the carbon footprint of their operations. From the use of solar energy to optimize energy consumption to the implementation of efficient heating systems, these factories are at the forefront of sustainable manufacturing practices.

Quality Control and TestingEnsuring the quality of ceramic coated non-stick plates is a critical aspect of the manufacturing process. Advanced factories have implemented rigorous quality control measures that include regular testing of the coatings for adherence, non-stick properties, and heat resistance. These tests are conducted throughout the production line to guarantee that every plate meets the highest standards before it reaches the consumer.

Integration of Smart TechnologyThe integration of smart technology into the manufacturing process has been a recent development. Factories are now using sensors and software to monitor the entire production process, from raw material handling to the final packaging. This real-time data allows for immediate adjustments and ensures that the manufacturing process is as efficient and precise as possible.

In conclusion, the manufacturing process of ceramic coated non-stick plates has seen a remarkable transformation. From the development of safer, more durable coatings to the adoption of energy-efficient and smart technologies, these innovations have made ceramic coated non-stick plates not just a kitchen staple but a symbol of cutting-edge manufacturing excellence.

Ceramic coated non-stick plates have seen a surge in popularity, reflecting a shift in consumer preferences towards healthier, more durable, and eco-friendly kitchenware. Let’s delve into the current market trends and the evolving choices that consumers are gravitating towards.

The demand for ceramic-coated cookware has been fueled by a growing awareness of the potential health risks associated with traditional non-stick coatings. Consumers are increasingly concerned about the release of harmful chemicals like PFOA and PTFE when cooking at high temperatures, which can lead to long-term health issues. As a result, ceramic coatings have become a preferred alternative, offering a non-toxic and durable cooking surface.

Eco-consciousness is another driving force behind the popularity of ceramic coated non-stick plates. With environmental concerns on the rise, consumers are looking for products that are sustainable and have a lower carbon footprint. Ceramic coatings are derived from natural minerals and are recyclable, aligning with the values of a greener lifestyle.

The trend towards minimalist and sleek kitchen designs has also played a significant role in the market’s preference for ceramic coated non-stick plates. These cookware pieces often come in a variety of modern colors and finishes, making them a stylish addition to any kitchen. Their sleek appearance and ease of cleaning contribute to a clutter-free and visually appealing kitchen space.

Smart technology integration is becoming more common in kitchenware, and ceramic coated non-stick plates are not immune to this trend. Smart cookware that can connect to smartphones or kitchen appliances through apps is gaining traction. Consumers are interested in products that not only improve their cooking experience but also offer convenience and connectivity.

The rise of home cooking and baking has spurred a demand for high-quality cookware that can handle a range of recipes. Ceramic coatings provide excellent heat retention and distribution, making them ideal for searing, sautéing, and baking. This versatility has made ceramic coated non-stick plates a must-have for aspiring chefs and home cooks alike.

Health and wellness have become central themes in consumer purchasing decisions. People are not just looking for a cooking surface that doesn’t stick, but also one that can withstand high temperatures without releasing harmful substances. Ceramic coatings have a higher heat resistance compared to traditional non-stick coatings, which is a significant factor in their popularity.

There’s also a trend towards multipurpose cookware. Consumers are seeking products that can serve multiple functions, such as ceramic coated non-stick plates that can be used for induction cooking, which is becoming more prevalent in modern kitchens. This versatility means fewer specialized tools are needed, simplifying kitchen storage and maintenance.

In terms of design, the market is seeing a move away from the traditional round or square cookware shapes. Consumers are now opting for unique and functional designs, such as square griddles and round woks with ceramic coatings. These shapes not only offer practical advantages but also add a touch of personality to the kitchen.

Personalization is another trend that’s shaping the market. Consumers are looking for cookware that reflects their individual style and preferences. Ceramic coated non-stick plates are now available with custom designs, allowing customers to choose their favorite colors or patterns, making each piece a unique addition to their kitchenware collection.

Lastly, the global pandemic has had a lasting impact on consumer behavior. With more people cooking at home, there has been a heightened focus on kitchen safety and hygiene. Ceramic coated non-stick plates, with their non-porous surfaces that resist bacteria growth, have become a staple in many households.

In conclusion, the market trends and consumer preferences in the ceramic coated non-stick plate industry are diverse and multifaceted. They range from health and environmental concerns to design aesthetics and technological advancements. As these trends continue to evolve, manufacturers are responding with innovative products that cater to the changing demands of the market.

In recent years, the demand for ceramic coated non-stick plates has surged across the globe, reflecting a shift in consumer preferences and a growing awareness of health and environmental concerns. This surge is driven by several key factors that have significantly impacted the global market.

The Health FactorConsumers are increasingly conscious of the health implications of non-stick cookware. Traditional non-stick coatings, often containing perfluorooctanoic acid (PFOA), have been linked to potential health risks. Ceramic coatings, on the other hand, are free from these harmful chemicals, making them a more attractive option for health-conscious consumers. This shift has fueled a substantial demand for ceramic coated non-stick plates worldwide.

Sustainability and Eco-Friendly PracticesAs the world grapples with environmental challenges, there’s a growing trend towards sustainable living. Ceramic coatings are considered more eco-friendly than traditional non-stick coatings because they are less likely to degrade and release harmful substances into the environment. This environmental consciousness has played a pivotal role in driving the global demand for ceramic coated non-stick plates.

Durability and PerformanceCeramic coated non-stick plates are not only free from harmful chemicals but also boast superior durability and performance. They can withstand higher temperatures than their traditional counterparts without degrading, making them a favorite among professional chefs and home cooks alike. The combination of health, environmental benefits, and excellent cooking performance has made ceramic coated plates a sought-after product globally.

Evolving Consumer PreferencesConsumer preferences have evolved significantly, with a strong emphasis on ease of use, convenience, and aesthetic appeal. Ceramic coated non-stick plates cater to these preferences by offering a sleek, modern look and a cookware experience that is both efficient and user-friendly. The plates’ ability to prevent food from sticking, reduce the need for excessive oil, and be washed easily has made them a staple in many kitchens around the world.

Cultural AdaptabilityThe global market for ceramic coated non-stick plates has expanded due to their adaptability to various culinary traditions. Whether it’s a stir-fry in Asia, a casserole in Europe, or a barbecue in the Americas, these plates can handle a wide range of cooking methods and ingredients. This versatility has made them a universal choice for consumers with diverse cooking habits and preferences.

E-commerce and AccessibilityThe rise of e-commerce has made ceramic coated non-stick plates more accessible to consumers worldwide. Online marketplaces have eliminated geographical barriers, allowing customers in remote areas to purchase these products with ease. The convenience of online shopping has contributed to the global demand for ceramic coated non-stick plates, as more people discover the benefits of these innovative cookware items.

Marketing and Branding StrategiesEffective marketing and branding have also played a significant role in the global demand for ceramic coated non-stick plates. Companies have leveraged social media, influencer partnerships, and targeted advertising campaigns to promote the health and environmental benefits of these products. As a result, ceramic coated non-stick plates have become a household name, driving sales across the globe.

Competitive PricingAnother factor contributing to the global demand is competitive pricing. As the manufacturing process has improved and production scales have increased, the cost of ceramic coated non-stick plates has become more affordable. This has made them a viable option for budget-conscious consumers, further boosting the global market.

Innovation in Design and FunctionalityThe continuous innovation in design and functionality has kept ceramic coated non-stick plates at the forefront of consumer demand. Manufacturers are constantly introducing new features, such as reinforced edges, ergonomic handles, and improved non-stick coatings, to enhance user experience. These innovations have helped maintain the product’s popularity and relevance in the global market.

The global demand for ceramic coated non-stick plates is a testament to the changing landscape of kitchenware preferences. As consumers continue to prioritize health, sustainability, and performance, the market for these innovative cookware items is expected to grow further, with a global reach that spans every corner of the world.

In the ever-evolving kitchenware market, ceramic coated non-stick plates have emerged as a game-changer. As we delve into the challenges and opportunities within the industry, it’s clear that while hurdles exist, the potential for growth and innovation is substantial.

The demand for non-stick cookware has surged, driven by busy lifestyles and health-conscious consumers seeking alternatives to traditional Teflon-coated pans. However, the industry faces several challenges that must be addressed to capitalize on the opportunities at hand.

One significant challenge is the environmental impact of non-stick coatings, particularly when they wear down or are improperly disposed of. The chemical PFOA, often found in older non-stick coatings, has been linked to health issues, prompting a shift towards more sustainable options. Ceramic coatings, while initially a bit pricier, offer a greener alternative that appeals to eco-friendly shoppers.

Another challenge is the perception of durability. While ceramic coatings are known for their longevity, some consumers are hesitant to invest in them due to concerns about scratching or peeling. Factories must focus on enhancing the quality of their coatings and educating consumers about proper care to build trust in their products.

On the flip side, opportunities abound. The rise of health trends, such as clean eating and the avoidance of artificial chemicals, has fueled demand for ceramic-coated non-stick plates. These plates are not only free from harmful chemicals but also boast superior non-stick properties that reduce the need for excessive oil, making them a favorite among health enthusiasts.

The digital age has also opened up new opportunities. E-commerce platforms have made it easier for manufacturers to reach a global audience, bypassing the need for traditional retail channels. Social media influencers and cooking bloggers are increasingly promoting ceramic-coated non-stick plates, creating a buzz that can drive sales.

Furthermore, customization is a key opportunity. Factories can differentiate their products by offering a wide range of colors, designs, and sizes to cater to diverse consumer preferences. This not only adds value to the product but also allows for niche marketing strategies.

The industry also benefits from advancements in technology. New techniques for applying ceramic coatings have been developed, resulting in a more even distribution and a stronger bond between the coating and the base material. This has led to improved performance and a longer lifespan for the cookware.

In terms of market expansion, there’s a vast potential in emerging markets. As consumers in these regions become more affluent and health-aware, they are likely to embrace ceramic-coated non-stick plates as a premium product. This presents an opportunity for factories to establish themselves in these markets and capture a significant share of the growing demand.

However, challenges persist. The cost of production can be higher due to the specialized materials and manufacturing processes required for ceramic coatings. Factories must find ways to optimize their supply chains and production methods to keep costs competitive without compromising on quality.

Additionally, regulatory compliance is a critical challenge. Manufacturers must stay abreast of changing regulations regarding chemical content and environmental impact. This requires a significant investment in research and development to ensure products meet the latest standards.

Despite these challenges, the opportunities in the ceramic coated non-stick plate industry are ripe for the taking. By focusing on sustainability, durability, innovation, and market expansion, factories can navigate the complexities of the market and emerge as leaders in the field. The key lies in understanding consumer needs, adapting to market trends, and leveraging technology to create a product that not only performs well but also resonates with the values of the modern consumer.

The factory, nestled in the heart of a bustling industrial park, has become a beacon of innovation in the ceramic coated non-stick plates industry. With state-of-the-art machinery and a team of dedicated professionals, it stands out as a testament to the evolution of cookware manufacturing.

In the heart of the production line, rows of workers, each equipped with precision tools, meticulously inspect and assemble the plates. The factory’s commitment to quality is evident in every detail, from the high-grade materials used to the stringent quality control measures in place.

The factory’s design philosophy revolves around sustainability and efficiency. It has implemented energy-saving systems that reduce the carbon footprint while maintaining production output. The use of renewable energy sources and waste reduction programs are just a few of the eco-friendly practices that set this factory apart.

Innovation is at the core of the factory’s operations. Continuous research and development efforts have led to the creation of a unique ceramic coating formula that offers superior non-stick properties. This formula is the result of years of testing and refinement, ensuring that the products meet the highest standards of performance and durability.

The factory’s customer base spans across the globe, with a particular focus on markets that prioritize health and safety in kitchenware. International certifications and compliance with various global standards are a testament to the factory’s dedication to meeting diverse customer needs.

The factory’s approach to marketing is as innovative as its manufacturing process. It leverages digital platforms to connect with customers worldwide, offering personalized shopping experiences and detailed product information. Social media campaigns and online tutorials have become key tools in showcasing the versatility and ease of use of their ceramic coated non-stick plates.

In the realm of human resources, the factory prides itself on fostering a diverse and inclusive work environment. Employees are provided with continuous training and development opportunities, ensuring that they stay at the forefront of industry trends. This emphasis on employee well-being has translated into high retention rates and a loyal workforce.

The factory’s supply chain is a marvel of efficiency. By partnering with local suppliers, they ensure a steady flow of high-quality materials, reducing transportation costs and environmental impact. This localized approach also supports the local economy and communities.

Despite the factory’s success, challenges remain. The rapid pace of technological advancements requires constant investment in new equipment and training. Moreover, the global supply chain disruptions have posed logistical hurdles that need to be navigated with agility.

Amidst these challenges, opportunities arise. The factory is exploring new markets in emerging economies where there is a growing demand for high-quality cookware. Additionally, the factory is looking into expanding its product line to include eco-friendly kitchen accessories, capitalizing on the global shift towards sustainable living.

The factory’s commitment to excellence is not just reflected in its products but also in its corporate social responsibility initiatives. They actively participate in community outreach programs, supporting educational and environmental projects that align with their core values.

In conclusion, the leading ceramic coated non-stick plates factory is more than just a manufacturing facility; it’s a hub of innovation, sustainability, and community engagement. Its journey from a modest operation to a global leader in the industry is a story of resilience, vision, and a relentless pursuit of perfection.

In the ever-evolving world of cookware, embracing the future means understanding the innovations that drive progress. The future of cookware is not just about new materials or designs; it’s about sustainability, health, and ease of use. As we look ahead, the role of technology and consumer demands will continue to shape the industry. From smart appliances that adapt to your cooking style to eco-friendly materials that reduce waste, the future of cookware promises a seamless blend of convenience and responsibility. Here’s a glimpse into what lies ahead for the cookware industry.

The future of cookware is a testament to human ingenuity, blending the latest technological advancements with timeless culinary needs. Imagine a kitchen where the stove, oven, and cookware are all interconnected, providing real-time data on cooking temperatures and times. This level of precision not only ensures perfect results but also saves energy and reduces food waste.

Cookware manufacturers are increasingly focusing on sustainability, using recycled materials and eco-friendly coatings. The shift towards sustainability is not just a trend; it’s a necessity, as consumers become more environmentally conscious. As a result, we’re seeing a rise in cookware made from recycled stainless steel, aluminum, and even bamboo. These materials are not only sustainable but also offer the durability and performance that home cooks demand.

Health-conscious consumers are driving the demand for non-stick cookware that doesn’t leach harmful chemicals into food. The future of cookware will likely see a surge in ceramic coatings that are free from PFOA and PTFE, the chemicals found in traditional non-stick surfaces. These new coatings are not only safer but also more durable, lasting longer than their predecessors.

The convenience of cookware is also set to take a leap forward with the integration of smart technology. Imagine a pan that adjusts its temperature based on the type of food you’re cooking, or a pot that can be controlled remotely via your smartphone. These smart cookware products are not just a novelty; they’re designed to make cooking easier and more enjoyable for everyone, from beginners to seasoned chefs.

Cookware that’s designed to last is another key trend. With the rise of minimalist living, consumers are looking for cookware that combines functionality with a sleek, modern design. Cookware companies are responding by creating pieces that are not only beautiful but also built to withstand the test of time. This means investing in high-quality materials and ensuring that every piece is crafted with precision.

The global demand for ceramic coated non-stick plates reflects a broader shift in consumer preferences. People are seeking cookware that is not only easy to use but also versatile. These plates are perfect for everything from searing steaks to simmering soups, making them a staple in kitchens around the world. The demand for these plates is only expected to grow as more consumers become aware of their benefits.

Innovation in the industry is not limited to materials and design; it’s also about how cookware is used and maintained. Companies are exploring new ways to educate consumers on proper care and cleaning techniques, ensuring that their products last as long as possible. This includes the development of cleaning solutions that are gentle on the cookware and the environment.

The challenges and opportunities in the cookware industry are immense. On one hand, there’s the pressure to keep up with rapidly changing consumer demands. On the other hand, there’s the opportunity to lead the charge in sustainability and health. As the industry continues to evolve, those who adapt and innovate will be the ones that thrive.

In conclusion, the future of cookware is bright and full of possibilities. It’s a future where technology, sustainability, and consumer needs converge to create a more efficient, healthier, and enjoyable cooking experience. As we move forward, it’s clear that the cookware industry is poised to play a significant role in shaping the way we cook and live.