Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As we delve into the world of commercial air fryers, it’s fascinating to observe how this industry has evolved. Once a niche product, these fryers have now become a staple in countless commercial kitchens. The advancements in design and functionality have not only transformed the way food is cooked but have also paved the way for a more efficient and sustainable future. Join us as we explore the competitive landscape, data-driven insights, and the ever-growing prospects of this innovative sector.

The Rise of Commercial Air Fryers

Commercial air fryers have emerged as a game-changer in the culinary world, revolutionizing the way food is prepared in restaurants, cafes, and commercial kitchens. This surge in popularity can be attributed to a combination of factors that have transformed the landscape of commercial cooking.

The convenience of air frying has been a significant draw for businesses looking to streamline their operations. These fryers offer a quick and efficient way to cook a variety of foods with minimal oil, which not only reduces preparation time but also slashes the cleanup. Chefs and kitchen managers alike appreciate the ability to serve crispy, golden-brown dishes without the mess and health concerns associated with traditional deep-frying.

Health consciousness has played a pivotal role in the rise of commercial air fryers. With the growing awareness of the health benefits of cooking with less oil, these fryers have become a favorite among establishments aiming to offer healthier menu options. The ability to achieve a similar texture and flavor profile as deep-fried foods without the guilt has made air fryers a must-have in many kitchens.

Moreover, the versatility of commercial air fryers cannot be overstated. They can handle a wide range of dishes, from appetizers like crispy onion rings and mozzarella sticks to main courses such as chicken, fish, and vegetables. This adaptability means that restaurants can diversify their menus without the need for multiple cooking appliances, saving both space and energy.

The technology behind commercial air fryers has also evolved significantly. Modern fryers are equipped with features like adjustable temperature controls, timers, and even programmable settings that allow for precise cooking. This precision is crucial in maintaining consistency across a high volume of orders, a common requirement in commercial kitchens.

As the demand for commercial air fryers has surged, so too has the competition among manufacturers. This competition has driven innovation, with companies constantly seeking to outdo each other with new features and improved designs. From countertop models to built-in units, the variety of air fryers available has expanded, catering to the diverse needs of different kitchen layouts and cooking styles.

Another factor contributing to the rise of commercial air fryers is the cost-effectiveness. Despite their initial investment, these fryers tend to be more energy-efficient than traditional fryers, leading to lower operational costs over time. The long-term savings, combined with the health benefits and operational advantages, make air fryers a compelling choice for businesses looking to enhance their profitability.

The environmental impact of commercial cooking has also come under scrutiny, and air fryers have stepped in as a more sustainable alternative. By reducing the amount of oil used and minimizing energy consumption, these fryers are helping kitchens reduce their carbon footprint. This eco-friendly aspect is becoming increasingly important to consumers and businesses alike, further propelling the popularity of air fryers.

Furthermore, the integration of air fryers into commercial kitchens has been facilitated by the rise of smart technology. Many modern fryers come with digital interfaces that allow for easy monitoring and control, even from a distance. This connectivity not only enhances convenience but also provides valuable data that can help kitchens optimize their operations and reduce waste.

The success of commercial air fryers is not just a trend; it’s a testament to the power of innovation in the foodservice industry. As consumer preferences continue to shift towards healthier options and more efficient cooking methods, it’s clear that commercial air fryers are here to stay, reshaping the way we think about fast and delicious food.

As the culinary world evolves, so too does the technology that chefs and foodservice professionals rely on. The evolution of commercial air fryer factories has been a fascinating journey, marked by innovation and a relentless pursuit of healthier cooking methods. From humble beginnings to cutting-edge production, here’s a look at how commercial air fryer factories have transformed over the years.

Once considered a niche product, the commercial air fryer has surged in popularity due to its ability to offer a healthier alternative to deep-frying. Early models were rudimentary, with basic features and limited capabilities. However, these early versions laid the groundwork for a technology that would soon revolutionize the kitchen.

The first generation of commercial air fryers were often large and bulky, occupying significant space in the kitchen. Despite their size, these early fryers were praised for their efficiency, which was a significant step up from traditional deep-frying methods. As time went on, engineers began to refine the design, focusing on reducing the footprint without compromising performance.

As consumer demand grew, so did the need for more sophisticated features. Commercial air fryer factories responded by introducing programmable settings, allowing users to tailor the cooking process to specific foods. This not only made the fryers more versatile but also simplified the cooking experience for busy chefs.

The mid-2000s saw a surge in the development of convection oven technology, which began to merge with the air fryer concept. This integration brought about the introduction of hybrid appliances, combining the health benefits of air frying with the even cooking of a convection oven. This evolution marked a significant shift in how air fryers were perceived and used in commercial kitchens.

Energy efficiency became a critical factor as environmental concerns grew. Commercial air fryer factories started to focus on reducing energy consumption, leading to the development of more energy-efficient units. These improvements were not just environmentally friendly but also cost-effective for businesses.

The advent of the digital age brought with it a new wave of innovation. Modern commercial air fryer factories now employ sophisticated software and robotics in their production processes. This has led to increased precision in assembly, reduced waste, and a shorter production time.

One of the most notable changes in recent years has been the emphasis on safety. Early models were often considered risky due to the potential for hot surfaces and oil spills. Today, commercial air fryer factories prioritize safety features such as automatic shut-off, non-slip bases, and tamper-resistant components.

The rise of smart kitchen technology has also had a significant impact on commercial air fryer production. Modern fryers can now be controlled remotely, providing chefs with the flexibility to manage cooking times and temperatures from anywhere in the kitchen. This level of connectivity has further streamlined operations and increased productivity.

Customization has become another hallmark of the modern commercial air fryer factory. With a wide range of models available, these factories can cater to the specific needs of various foodservice operators. From countertop units to large-scale industrial fryers, the variety is almost limitless.

The evolution of commercial air fryer factories has been a testament to the power of innovation. From simple appliances to sophisticated systems, these factories have continuously pushed the boundaries of what is possible. As the culinary world continues to change, it’s clear that the future of commercial air fryer production is bright, with endless possibilities for further advancements.

The evolution of commercial air fryer factories has brought about a wave of innovative designs and functionalities that have revolutionized the culinary industry. From compact units to those with advanced capabilities, the journey has been marked by continuous improvements aimed at efficiency, ease of use, and health benefits.

Compact and Efficient UnitsCommercial air fryers have shrunk in size without compromising on performance. Modern units are now more compact, allowing for easier installation in limited kitchen spaces. This space-saving design has made air fryers a popular choice in fast-food restaurants, cafes, and even busy commercial kitchens where every inch counts.

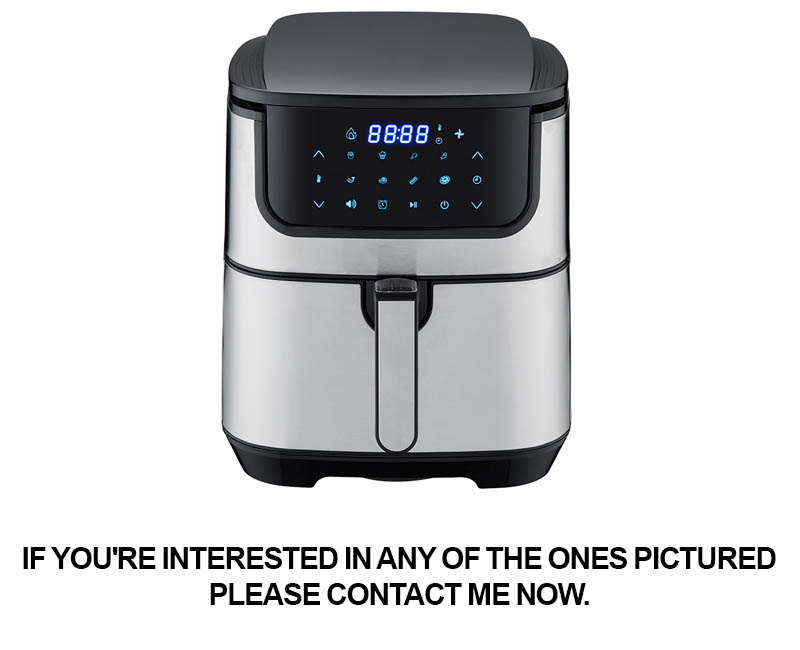

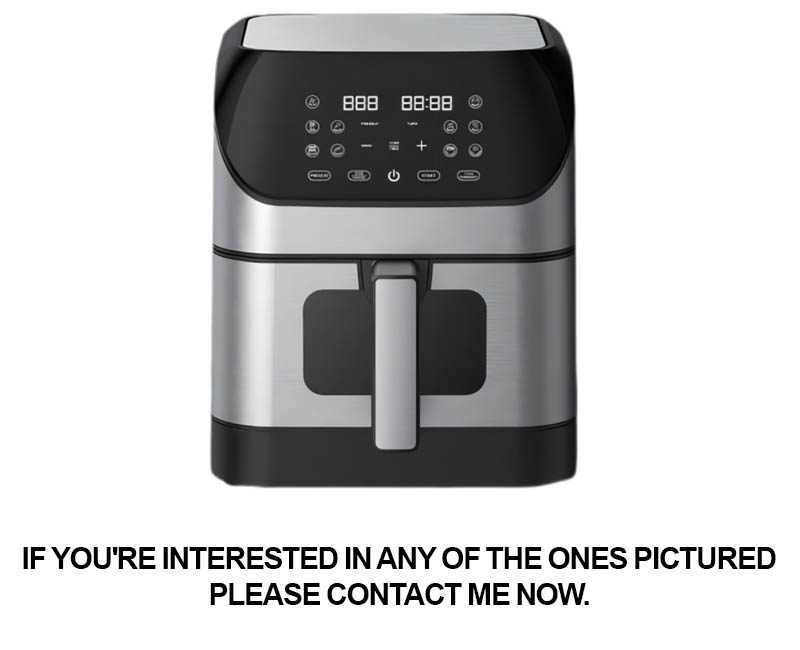

Advanced Temperature ControlOne of the key innovations in commercial air fryers is the introduction of precise temperature control. These fryers now come with digital displays and programmable settings, allowing chefs to cook a variety of foods at the ideal temperature. This ensures that food is cooked to perfection, whether it’s crispy French fries or tender chicken wings.

Multi-FunctionalityCommercial air fryer factories have expanded the capabilities of these appliances beyond just frying. Many models now feature additional functions such as roasting, baking, and dehydrating. This versatility allows chefs to use a single appliance for a multitude of cooking tasks, reducing the need for additional kitchen equipment and streamlining the cooking process.

Smart Features and ConnectivityIncorporating smart technology, modern commercial air fryers are now more user-friendly than ever. With features like timers, auto-shutoff, and programmable cook cycles, these appliances can be set and forgotten. Some models even offer wireless connectivity, allowing operators to control the fryer remotely via an app on their smartphone or tablet.

Enhanced Safety FeaturesSafety has always been a priority in commercial kitchen equipment, and air fryers are no exception. Newer models come with safety features like cool-to-the-touch exteriors, non-slip bases, and childproof locks. These features not only protect kitchen staff but also ensure that the fryer is safe to use around children and the elderly.

Energy EfficiencyEfficiency is a major concern in commercial operations, and air fryers have become increasingly energy-efficient. Modern units use significantly less oil than traditional fryers, reducing both operational costs and waste. The rapid heat-up time and shorter cooking cycles also contribute to lower energy consumption.

Eco-Friendly MaterialsSustainability is at the forefront of the commercial air fryer industry. Factories are now using eco-friendly materials in the construction of these appliances. Recyclable materials, reduced packaging, and energy-saving production processes are just a few ways that air fryer factories are contributing to a greener future.

Customizable and Modular DesignFor large-scale operations, commercial air fryer factories are offering customizable and modular designs. This allows businesses to tailor the fryer to their specific needs, whether it’s increasing capacity or integrating it into existing kitchen layouts. Such flexibility is crucial for busy kitchens looking to optimize their workflow.

Enhanced Performance with New TechnologiesThe integration of new technologies such as magnetic fields and advanced heat distribution systems has significantly improved the performance of commercial air fryers. These technologies ensure even cooking and faster frying times, which is a game-changer for high-volume kitchens.

Diverse Menu OptionsWith the introduction of these innovative designs and functionalities, commercial air fryers are enabling chefs to offer a wider range of menu items. From gourmet snacks to healthy alternatives, the versatility of these fryers is expanding the culinary possibilities in commercial kitchens across the globe.

The market for commercial air fryers has seen a surge in demand, driven by a combination of health-conscious consumers and the culinary industry’s quest for efficiency. This shift has led to a fascinating evolution in design and functionality, with manufacturers pushing the boundaries of what these appliances can do.

One of the most significant trends in the commercial air fryer market is the emphasis on health and wellness. As consumers become more aware of the nutritional impact of cooking methods, there’s a growing preference for appliances that offer healthier alternatives to deep-frying. This has spurred manufacturers to create air fryers that not only cook food with less oil but also maintain its natural flavors and textures.

Commercial air fryer factories have responded to this demand by integrating advanced cooking capabilities. Modern models now come with features like adjustable temperature controls, which allow chefs to tailor the cooking process to specific foods. Some units even offer programmable settings, enabling the preparation of a variety of dishes with a single appliance.

Capacity has become a key factor in the design of commercial air fryers. With the rise of fast-casual dining and the need for quick, large-scale food preparation, these appliances now come in larger sizes, capable of frying large batches of food. Additionally, many models are designed to be stackable or modular, saving valuable kitchen space and allowing for multi-functional cooking stations.

Energy efficiency is another crucial aspect that has seen innovation. As environmental concerns grow, commercial air fryer factories are focusing on creating appliances that consume less energy while still delivering high performance. This not only helps businesses reduce their operational costs but also aligns with the broader sustainability goals of the industry.

The user interface has also evolved to become more intuitive and user-friendly. Modern commercial air fryers often feature digital displays, touchscreens, and easy-to-read LED indicators. These advancements make it simpler for operators to monitor cooking times and temperatures, ensuring consistent results every time.

Safety has always been a priority in kitchen appliances, and commercial air fryers are no exception. Newer models come with safety features such as automatic shut-off functions, which turn off the appliance after a certain period of inactivity or when the cooking process is complete. Some even have non-slip bases and cool-touch exteriors to prevent accidents.

For businesses looking to differentiate their offerings, commercial air fryer factories are now offering customization options. This includes branding the appliances with a company logo or customizing the color to match the kitchen’s aesthetic. Such personal touches can enhance the brand image and provide a unique selling point.

The integration of smart technology is becoming increasingly common in commercial air fryers. Some models can be controlled remotely through smartphones or tablets, allowing operators to manage cooking processes even when they’re not in the kitchen. This level of connectivity and control is particularly valuable in busy commercial kitchens where efficiency is paramount.

In line with the broader trend towards sustainability, commercial air fryer factories are also focusing on using eco-friendly materials in their products. This includes recyclable components and energy-efficient materials that contribute to a reduced carbon footprint.

Finally, many commercial air fryers now offer customizable cooking programs, allowing chefs to save their preferred settings for different types of food. This not only saves time but also ensures that each dish is cooked to perfection, every time.

The evolution of commercial air fryer factories reflects a deep understanding of the market’s needs and a commitment to innovation. As consumer preferences continue to shift towards healthier and more efficient cooking methods, these factories are at the forefront, driving the next wave of technological advancements in the commercial kitchen industry.

In recent years, the commercial air fryer industry has seen a remarkable transformation, driven by a growing demand for healthier cooking methods and increased efficiency. As these appliances become more prevalent in professional kitchens, their design and functionality have evolved significantly. Here’s a closer look at some of the innovations shaping the commercial air fryer market.

Compact and Modular DesignsCommercial air fryers have shrunk in size without compromising on performance. Modern units are now more compact, allowing for easier integration into kitchen layouts and freeing up valuable counter space. Many models come with modular components, making them adaptable to various cooking environments and easy to clean.

Advanced Heat DistributionInnovations in heat distribution have led to more even cooking and reduced cooking times. Newer models feature advanced fans and heating elements that ensure food is fried evenly, resulting in consistent texture and taste. Some fryers also incorporate temperature control systems that prevent overcooking and burning.

Smart Technology IntegrationSmart technology has become a staple in the commercial air fryer market. Many units now come with digital interfaces that allow for precise temperature and time settings. Some fryers can even be controlled remotely through smartphones or tablets, offering chefs the flexibility to manage cooking processes from anywhere in the kitchen.

Energy EfficiencyEfficiency is a key concern in the commercial kitchen environment. Air fryers have become more energy-efficient, consuming less power than traditional fryers. This not only reduces operating costs but also has a positive impact on the environment. Energy-saving features, such as automatic shut-off and optimized heating elements, are becoming standard in new models.

Enhanced CapacityAs demand for larger batches of food has increased, commercial air fryer manufacturers have responded with units that can accommodate more food at once. Larger capacities allow for more efficient cooking sessions, reducing the need for multiple batches and streamlining kitchen operations.

Customizable Cooking ProgramsModern commercial air fryers offer a range of customizable cooking programs, allowing chefs to tailor the cooking process to specific recipes. These programs can be saved and reused, ensuring consistent results every time. Some fryers even have pre-programmed settings for popular dishes, making it easier for staff to operate the equipment.

Easy-to-Clean SurfacesMaintaining cleanliness is crucial in commercial kitchens, and the design of air fryers has evolved to make cleaning easier. Non-stick surfaces, removable parts, and self-cleaning modes are becoming more common, reducing the time and effort required to keep the fryer in top condition.

Safety FeaturesThe safety of kitchen staff and customers is paramount. Newer models come with safety features like child locks, non-slip bases, and automatic cooling fans that prevent overheating. These innovations ensure that the fryers are both reliable and safe to use.

Eco-Friendly MaterialsAs sustainability becomes a more pressing issue, commercial air fryer factories are increasingly using eco-friendly materials. Biodegradable parts, recycled components, and energy-efficient manufacturing processes are all part of the push towards greener appliances.

Integration with Other Kitchen EquipmentModern commercial air fryers are designed to work seamlessly with other kitchen equipment. They often come with features that allow for easy integration into existing kitchen layouts, such as adjustable legs and built-in timers that can be synchronized with other appliances.

The evolution of commercial air fryers reflects the industry’s commitment to meeting the demands of professional chefs and foodservice operators. With these innovations, the commercial air fryer has become a versatile, efficient, and sustainable solution for kitchens worldwide.

In the bustling commercial kitchen industry, the competitive landscape for air fryer factories is a dynamic and evolving environment. Brands vie for market share with innovative products, strategic partnerships, and a keen understanding of customer needs. Here’s a glimpse into the competitive world of commercial air fryer factories:

Technological Advancements Drive CompetitionThe market is flooded with air fryer factories that pride themselves on technological breakthroughs. From high-precision temperature control to programmable settings, these advancements ensure that food is cooked to perfection with minimal effort. The race to integrate smart technology into air fryers has intensified, with manufacturers aiming to offer solutions that not only streamline operations but also enhance the cooking experience.

Diverse Product LinesCompetitive air fryer factories often offer a wide range of products to cater to different segments of the market. From countertop models for small-scale operations to industrial-grade fryers for large restaurants, the variety allows manufacturers to reach a broader audience. This diversity in product lines is a key strategy for staying competitive, as it ensures that each customer’s specific needs can be met.

Focus on Health and WellnessWith health concerns on the rise, there’s a growing emphasis on healthier cooking options. Air fryer factories that can offer low-fat, low-calorie alternatives without compromising on taste have a competitive edge. The market is witnessing a surge in air fryers designed to be healthier options for both consumers and operators, reflecting a shift in consumer preferences towards wellness.

Strategic Partnerships and CollaborationsTo maintain a competitive edge, air fryer factories are forming strategic partnerships with foodservice operators, distributors, and even technology companies. These collaborations can range from joint product development to co-branded marketing campaigns. By teaming up with industry leaders, manufacturers can gain access to new markets, resources, and customer insights.

Quality Control and ReliabilityIn a competitive market, the reliability and durability of products are paramount. Air fryer factories that prioritize quality control and ensure that their products are built to last have a significant advantage. The reputation for producing robust, long-lasting air fryers can be a powerful selling point, as operators seek to invest in equipment that won’t require frequent repairs or replacements.

Environmental ConsiderationsSustainability is becoming a critical factor in the competitive landscape. Air fryer factories that can demonstrate their commitment to the environment through eco-friendly practices and energy-efficient designs are gaining ground. This includes using recycled materials, reducing waste during production, and offering energy-saving features in their air fryers.

Marketing and BrandingThe way air fryer factories market their products can significantly impact their competitive position. Effective branding and marketing strategies help to differentiate a company’s offerings in a crowded market. From social media campaigns to trade show participation, the ability to communicate the unique selling points of a product is essential for standing out.

Customer Service and SupportIn the competitive air fryer market, excellent customer service can be a differentiator. Factories that offer superior after-sales support, including training, maintenance, and warranty services, are more likely to retain customers. A reputation for exceptional customer service can lead to repeat business and positive word-of-mouth referrals.

Global ExpansionAs the demand for air fryers grows internationally, so does the need for global expansion. Competitive factories are seeking to enter new markets by adapting their products to local regulations, preferences, and culinary traditions. This global approach is not only about expanding sales but also about building a strong brand presence worldwide.

Continuous InnovationFinally, the most enduring competitive advantage is the ability to innovate continuously. Air fryer factories that invest in research and development to stay ahead of the curve will likely maintain their competitive edge. Whether it’s through new cooking techniques, improved energy efficiency, or unique design features, innovation is the cornerstone of long-term success in the air fryer market.

In the realm of commercial air fryer factories, data-driven insights are reshaping the industry with precision and foresight. Here’s an exploration of how these insights are being utilized:

The integration of smart technology has allowed for real-time monitoring of air fryer performance, enabling factories to track energy consumption, cooking times, and efficiency metrics. This data not only helps in optimizing the manufacturing process but also ensures that the end product meets the highest standards of quality and performance.

Consumer feedback and market research have become crucial in guiding product development. By analyzing purchasing patterns and usage statistics, factories can identify trends and preferences that influence design choices. For instance, a surge in demand for larger capacity units indicates a shift towards family-sized cooking solutions.

Predictive analytics are being used to forecast future market demands, allowing factories to anticipate trends and invest in the right technology and resources. This forward-thinking approach minimizes the risk of overproduction and ensures that inventory is aligned with consumer needs.

Data analytics have also revealed insights into the environmental impact of air fryer production. By tracking emissions and waste generation, factories are able to implement more sustainable practices, from sourcing eco-friendly materials to optimizing recycling processes.

The use of customer relationship management (CRM) systems has enabled factories to gain a deeper understanding of their client base. This includes identifying which features are most valued by different segments of the market, such as restaurants, hotels, and caterers, and tailoring product offerings accordingly.

Innovation in air fryer design is being fueled by data that shows a preference for compact and space-saving models. This has led to the development of air fryers that are not only efficient but also fit seamlessly into the limited kitchen space often found in commercial settings.

Maintenance and repair data are being meticulously analyzed to improve product reliability and reduce downtime. By understanding the most common issues faced by users, factories can design more robust appliances and provide better customer service.

The rise of subscription-based services has been identified as a key trend, with data indicating that businesses are increasingly looking for flexible and cost-effective solutions. Factories are responding by offering service packages that include regular maintenance, updates, and support.

In the realm of marketing, data-driven insights have transformed the approach to promotional strategies. By understanding which channels are most effective in reaching target audiences, factories can allocate their marketing budgets more efficiently.

The impact of social media and online reviews on consumer purchasing decisions cannot be overstated. Data analytics are being used to monitor and influence these platforms, ensuring that the brand image aligns with consumer expectations and market trends.

Lastly, data-driven insights are being used to create more personalized and engaging customer experiences. From tailored product recommendations to interactive digital platforms, the data collected from air fryer users is being leveraged to build stronger, more loyal customer relationships.

The commercial air fryer market is a dynamic landscape, characterized by fierce competition and relentless innovation. Brands are vying for market share, each striving to offer the latest technology and features that resonate with consumers. Here’s a closer look at the competitive nature of the commercial air fryer landscape:

Innovation in Technology- Brands are pushing the boundaries of technology, integrating smart features like touch screens, programmable settings, and remote monitoring.- The introduction of wireless connectivity has allowed for real-time data analysis, enhancing the user experience and operational efficiency.

Brand Differentiation- Companies are focusing on unique selling points (USPs) to stand out, whether it’s the speed of cooking, the capacity of the fryer, or the health benefits offered by air frying technology.- Some brands are emphasizing eco-friendly materials, while others tout the longevity and durability of their products.

Market Leadership- Established players are leveraging their brand recognition and distribution networks to maintain a competitive edge.- Newcomers, however, are using digital marketing and social media to create buzz and carve out a niche in the market.

Global Expansion- Many manufacturers are looking beyond domestic markets to expand their reach.- This global expansion is not just about selling products; it’s about adapting to local regulations, preferences, and cultural differences.

Strategic Partnerships- Collaborations with foodservice providers, retailers, and technology companies are becoming more common.- These partnerships can lead to co-branded products, shared research and development, and enhanced market penetration.

Consumer Trust- The competitive landscape is also shaped by consumer trust and brand loyalty.- Brands that invest in quality control, safety standards, and customer service tend to retain a loyal customer base.

Regulatory Compliance- As the market grows, so does the importance of regulatory compliance.- Manufacturers must navigate a complex web of safety standards, certifications, and labeling requirements across different regions.

Emerging Technologies- The integration of AI and machine learning could revolutionize the industry, offering predictive maintenance, energy optimization, and personalized cooking recommendations.- Some companies are exploring the use of blockchain to ensure product traceability and authenticity.

E-commerce Influence- The rise of e-commerce has reshaped the way products are sold, with online reviews and ratings playing a crucial role in consumer decision-making.- Brands that excel in online marketing and customer engagement are gaining a competitive advantage.

The competitive landscape of commercial air fryers is a multifaceted one, where innovation, strategy, and customer satisfaction are key drivers of success. As the industry continues to evolve, it’s clear that those who can adapt to changing consumer preferences and market dynamics will thrive.

In the world of commercial air fryer factories, there are several success stories that stand out as testament to the innovation and dedication of these companies. From small startups to established giants, these case studies showcase the diverse paths to success in this dynamic industry.

A local startup revolutionized the commercial kitchen scene with their compact, energy-efficient air fryers. Their product caught the attention of small-scale restaurants and cafes, offering them a healthier alternative to traditional fryers without the associated costs.

One global player in the industry expanded their line with a line of air fryers that catered to the specific needs of fast-food chains. The sleek design and rapid cooking capabilities were a hit, and the company quickly became the go-to brand for fast-casual restaurants worldwide.

A mid-sized manufacturer focused on customization, offering a range of air fryers tailored to the unique requirements of various cuisines. Their air fryers, which could handle everything from tempura to tortillas, were embraced by chefs looking to diversify their menus without compromising on quality.

A company known for their smart kitchen appliances integrated AI into their commercial air fryers. The result was a device that could optimize cooking times and temperatures based on the type of food being prepared, leading to increased efficiency and reduced energy consumption.

A group of entrepreneurs saw the potential in the rise of plant-based diets and developed a line of air fryers specifically designed for crispy, golden vegan snacks. Their innovative approach to healthier snacking options won over health-conscious consumers and businesses alike.

One of the oldest players in the market turned to innovation by introducing a line of air fryers that were not only energy-efficient but also designed with the environment in mind. The use of recycled materials and a focus on reducing waste in the manufacturing process won them both accolades and a loyal customer base.

A tech company that started in the consumer market decided to expand into the commercial sector with a line of air fryers that could be controlled remotely via an app. This allowed chefs to manage cooking times and temperatures from anywhere, a feature that was particularly attractive to busy kitchens.

A manufacturer that had traditionally focused on industrial ovens diversified into air fryers by leveraging their existing expertise in heat distribution. Their air fryers, with precise temperature control and even heat distribution, were well-received by users who appreciated the consistent results.

A company that specializes in commercial kitchen equipment partnered with a local food innovation lab to develop a line of air fryers that could handle a wide range of recipes with minimal adjustments. This collaboration resulted in a product that was both versatile and easy to use, making it a favorite among chefs who wanted to simplify their cooking process.

Each of these success stories is a reflection of the dynamic nature of the commercial air fryer industry. They demonstrate how companies are adapting to changing market demands, embracing technology, and focusing on sustainability to stay ahead in a competitive landscape. Whether through innovation, customization, or strategic partnerships, these companies have found their niche and are redefining what it means to cook healthily and efficiently in the commercial kitchen.

The integration of advanced technology has revolutionized the commercial air fryer industry, enhancing efficiency and productivity in kitchens around the world. From automation to data analytics, the role of technology is profound, and its impact is far-reaching.

Technological advancements have allowed for the creation of more precise and energy-efficient air fryers. These devices can now be programmed to specific temperature and cooking times, ensuring that food is cooked to perfection with minimal energy consumption. The precision in temperature control has also led to healthier cooking methods, as air fryers can achieve desired results with less oil than traditional frying methods.

Smart features are becoming increasingly common in commercial air fryers. With touchscreens and programmable settings, operators can easily adjust cooking parameters to suit various recipes and menu items. The inclusion of Wi-Fi connectivity has allowed for remote monitoring and control, which is particularly beneficial for multi-unit restaurant chains or facilities that operate around the clock.

Maintenance and cleaning have also been streamlined through technological innovations. Self-cleaning functions and easy-to-access components have reduced the time and effort required to keep air fryers in top condition. This not only improves operational efficiency but also extends the lifespan of the equipment.

In the realm of data analytics, technology is providing valuable insights into consumer behavior and kitchen performance. By collecting data on usage patterns, manufacturers can refine their products to better meet market demands. Additionally, operators can analyze data to optimize cooking processes, reduce waste, and enhance overall kitchen efficiency.

The rise of the Industrial Internet of Things (IIoT) has opened new avenues for the commercial air fryer industry. Sensors and connectivity allow for predictive maintenance, where machines can alert operators to potential issues before they become major problems. This proactive approach to maintenance can significantly reduce downtime and extend the life of equipment.

Energy management systems are another technological innovation that has found its way into commercial air fryers. These systems monitor and control the energy consumption of the fryer, ensuring that it operates at peak efficiency. In kitchens where energy costs are a significant concern, these systems can lead to substantial savings over time.

Safety features have also been enhanced through technology. Modern air fryers are equipped with overheat protection, which automatically shuts down the unit if it exceeds safe operating temperatures. This not only prevents fires but also ensures the safety of kitchen staff and customers.

From a consumer perspective, technology is influencing the types of air fryers that are being developed. There is a growing trend towards healthier, low-fat cooking options, which is prompting manufacturers to innovate in areas such as temperature distribution and cooking time optimization. This consumer-driven demand is shaping the direction of technological advancements in the industry.

In the culinary world, technology is also enabling new cooking techniques and flavor profiles. The ability to control cooking parameters with precision has allowed chefs to experiment with recipes and push the boundaries of what can be achieved with air fryers. This has opened up a world of possibilities for both commercial kitchens and consumers at home.

The role of technology in the commercial air fryer industry is undeniable. It has not only improved the efficiency and sustainability of kitchen operations but has also enhanced the consumer experience. As technology continues to evolve, we can expect to see even more innovative solutions that will further transform the way we cook and eat.