Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In today’s fast-paced world, the demand for quick and delicious meals has surged, and the sandwich grill plant has emerged as a cornerstone in the kitchen appliance industry. This innovative technology not only revolutionizes the way sandwiches are prepared but also presents a compelling business opportunity for entrepreneurs and restaurateurs alike. As we delve into the continuous operation sandwich grill plant, it becomes evident that this game-changer is more than just a kitchen gadget; it’s a catalyst for efficiency, growth, and customer satisfaction.

The sandwich, a beloved staple of fast food and casual dining, has evolved over the years from a simple meal to a culinary canvas. Amidst this transformation, the continuous operation sandwich grill plant has emerged as a pivotal player in the kitchen appliance industry. This innovative technology has not only streamlined the sandwich-making process but has also raised the bar for efficiency and quality in the fast-casual sector.

In the past, sandwich shops relied on manual grilling methods, which were time-consuming and limited in output. The introduction of the sandwich grill plant marked a significant shift, allowing for the production of sandwiches at a much faster pace. These plants have become the backbone of many sandwich shops, cafes, and even food trucks, ensuring that customers can enjoy their favorite grilled sandwiches quickly and consistently.

The rise of the sandwich grill plant can be attributed to several factors. Firstly, the increasing demand for convenience foods has driven the need for more efficient food production methods. With busy lifestyles and the pursuit of time-saving solutions, consumers are gravitating towards quick-service restaurants (QSRs) that offer sandwiches on the go. The continuous operation sandwich grill plant perfectly aligns with this consumer preference by providing a high-speed, reliable solution for sandwich production.

Secondly, the advent of health-conscious eating habits has also played a role in the growth of the sandwich grill plant market. As consumers seek out healthier alternatives to fast food, the demand for fresh, grilled sandwiches has surged. These sandwich grill plants are designed to cook sandwiches with minimal oil, making them a more nutritious choice compared to fried options.

The technology behind the sandwich grill plant is sophisticated yet surprisingly straightforward. These plants are equipped with conveyor belts and heating elements that can grill multiple sandwiches simultaneously. This not only increases production capacity but also ensures that each sandwich is cooked to perfection. The ability to maintain consistent temperatures and cooking times is crucial for the quality and taste of the sandwiches.

Moreover, the continuous operation nature of these plants is a game-changer. Unlike traditional grills that require frequent breaks for maintenance or cooling, these sandwich grill plants can run non-stop, 24⁄7. This means that sandwich shops can serve more customers in less time, maximizing their revenue potential.

The design of a modern sandwich grill plant is also focused on ease of use and maintenance. Operators can easily adjust settings, monitor the cooking process, and clean the equipment, which minimizes downtime and ensures that the plant operates smoothly. This user-friendly aspect is particularly appealing to businesses looking to streamline their operations without compromising on quality.

As the sandwich grill plant market continues to grow, it’s clear that innovation is key. Companies are constantly looking for ways to improve the efficiency and functionality of these plants. For instance, some models now come with integrated bread toasting functions, allowing for a complete sandwich-making experience in one machine. Others are exploring the use of renewable energy sources to make the plants more sustainable.

The rise of the sandwich grill plant has also had a ripple effect on the broader foodservice industry. Suppliers have responded by offering a wider variety of sandwich ingredients, including artisan breads, fresh vegetables, and high-quality meats. This has allowed sandwich shops to offer a diverse menu that caters to a wide range of tastes and dietary preferences.

In conclusion, the continuous operation sandwich grill plant has revolutionized the way sandwiches are made and served. By combining speed, efficiency, and quality, these plants have become an essential tool for any business looking to capitalize on the growing demand for quick, delicious sandwiches. As the market continues to evolve, we can expect to see even more innovative solutions that will further enhance the capabilities of the sandwich grill plant.

The continuous operation sandwich grill plant has revolutionized the way we think about commercial kitchen efficiency. By eliminating downtime and maximizing throughput, these advanced systems have become a cornerstone for businesses looking to stay ahead in the competitive foodservice industry.

In the fast-paced world of sandwich production, the ability to maintain a steady flow of fresh, hot sandwiches is crucial. Continuous operation grills are designed to do just that, providing a seamless production process that keeps customers satisfied and orders moving. The key advantage lies in their non-stop performance, allowing for a consistent output that far surpasses traditional grills.

One of the most significant benefits is the reduction in labor costs. With a continuous operation grill, the need for frequent breaks and manual reloading is minimized. Operators can focus on other tasks, knowing that the grill will keep running without interruption. This not only increases productivity but also allows for a more streamlined workflow.

Another advantage is the consistent quality of the sandwiches. These grills are engineered to maintain a precise temperature throughout the cooking process, ensuring that each sandwich is cooked to perfection. The even heat distribution prevents overcooking or undercooking, which can be a common issue with intermittent cooking appliances.

Energy efficiency is also a standout feature of continuous operation sandwich grill plants. By keeping the grill running at a consistent pace, energy consumption is optimized, leading to lower utility bills. This is particularly beneficial for businesses operating on tight profit margins, as every penny saved on energy can contribute to the bottom line.

The reliability of these grills is unmatched. They are built with robust components that can withstand the rigors of continuous use, reducing the likelihood of breakdowns and maintenance issues. This reliability translates into fewer unexpected downtime periods, which are costly for any business.

In terms of space utilization, continuous operation sandwich grill plants are designed to be compact yet efficient. They can be easily integrated into existing kitchen layouts, maximizing space without compromising on performance. This is especially important for establishments with limited kitchen space, such as food trucks or small cafes.

The speed of production is another advantage that cannot be overstated. These grills can cook multiple sandwiches at once, significantly reducing the wait time for customers. In a world where instant gratification is the norm, the ability to serve sandwiches quickly can be a major draw for customers seeking a quick bite.

The consistency of the product is also a testament to the continuous operation advantage. With each sandwich cooked under the same conditions, there is no variation in taste or texture. This predictability is crucial for businesses looking to establish a strong brand identity and reputation for quality.

The scalability of these grills is also noteworthy. As a business grows, so does the demand for increased production capacity. Continuous operation sandwich grill plants can be expanded to meet these needs, ensuring that the business can keep up with the demand without a loss in quality or service.

Lastly, the health and safety benefits of continuous operation grills cannot be ignored. By reducing the need for manual handling of hot sandwiches, the risk of burns and other injuries is minimized. This creates a safer work environment for kitchen staff.

In conclusion, the continuous operation sandwich grill plant offers a multitude of advantages that make it a compelling choice for any business in the sandwich industry. From increased efficiency and reduced labor costs to improved product quality and safety, these grills are changing the game for sandwich producers everywhere.

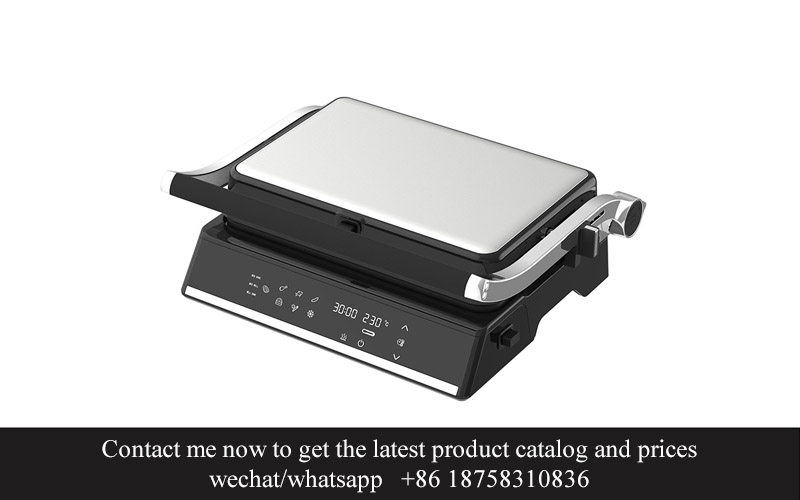

In the realm of commercial kitchen appliances, the sandwich grill plant stands out as a marvel of efficiency and innovation. Let’s delve into the key features that make these high-performance units the backbone of modern sandwich production.

The uniform heating system in a high-performance sandwich grill plant is its cornerstone. Precision engineering ensures that every element of the grill is designed to deliver consistent heat distribution across the entire cooking surface. This evenness is crucial for achieving that perfect golden-brown crust on both the bread and the fillings, every single time.

Durability is not just a buzzword but a reality in these grill plants. The construction often involves heavy-duty stainless steel, which not only withstands the rigors of constant use but also maintains its sleek appearance over time. The robust build means these grills can handle high volumes without succumbing to wear and tear.

The user interface is another standout feature. Modern sandwich grill plants come equipped with intuitive control panels that make operation a breeze. Touchscreens and programmable settings allow for easy adjustments to cooking temperatures, times, and even sequences, ensuring that operators can tailor the cooking process to the specific requirements of their menu items.

Efficiency is at the heart of a high-performance sandwich grill plant, and this is evident in the energy consumption. Advanced heating elements are designed to heat up quickly and maintain optimal temperatures with minimal energy usage, which is not only cost-effective but also environmentally friendly.

Safety features are integrated seamlessly into these grill plants. Overheat protection systems automatically shut down the grill if it reaches unsafe temperatures, preventing damage to the equipment and, more importantly, safeguarding the staff and customers from potential hazards.

In terms of design, these grills are not just functional but also space-saving. The compact and sleek design allows for easy integration into existing kitchen layouts without compromising on cooking capacity. This is particularly beneficial in fast-food restaurants and busy catering services where every inch of workspace counts.

The cleanliness of the sandwich grill plant is another key feature. With seamless surfaces and easy-to-clean components, maintaining hygiene standards is a straightforward task. This is essential for food safety and compliance with health regulations.

Innovation extends to the grill’s ability to handle different types of breads and fillings. With adjustable plates and heating elements that can accommodate a variety of sandwich sizes and ingredients, these units offer versatility that caters to a diverse range of sandwich styles.

Moreover, these grill plants often come with features like non-stick surfaces that reduce the need for butter or oil, enhancing both the taste of the sandwiches and the efficiency of the cooking process.

The ease of maintenance is a crucial aspect that cannot be overlooked. Regular cleaning and maintenance are simplified with accessible components and clear instructions, ensuring that the grill plant remains in top condition for years to come.

Lastly, the design of a high-performance sandwich grill plant often includes features that enhance the cooking experience, such as indicator lights for ready-to-cook sandwiches and adjustable heat zones for customized cooking profiles.

Each of these features contributes to the overall excellence of a high-performance sandwich grill plant, making it an invaluable asset in the fast-paced world of sandwich production.

In the ever-evolving landscape of the kitchen appliance industry, the demand for efficient and innovative solutions has surged. The rise of fast-casual dining has reshaped consumer preferences, leading to a surge in the popularity of sandwich shops and cafes. This shift has brought about a new wave of market trends and consumer demands that are reshaping the way sandwich grill plants are designed and operated.

The demand for convenience and speed in food service has driven the need for high-performance sandwich grill plants. Consumers are increasingly looking for quick and satisfying meals that they can enjoy on the go. This has led to a preference for sandwich shops that can churn out a large volume of sandwiches in a short amount of time.

One of the key trends is the focus on customization. Today’s customers expect to be able to tailor their meals to their personal tastes and dietary preferences. This means that sandwich grill plants must be equipped with versatile systems that can handle a variety of ingredients and toppings. From vegan and gluten-free options to gourmet fillings, the ability to adapt to these diverse requirements is crucial.

Moreover, there’s a growing emphasis on health and wellness. Consumers are more health-conscious than ever before, seeking out nutritious options that align with their lifestyle choices. This has prompted the inclusion of healthier ingredients in sandwich offerings, such as whole grains, lean proteins, and fresh vegetables. The sandwich grill plant must be capable of handling these ingredients with precision to ensure they retain their nutritional value and flavor.

The trend towards sustainability is also influencing the design of sandwich grill plants. With environmental concerns at the forefront, there’s a push for energy-efficient appliances and practices. This includes the use of eco-friendly materials, water-saving technologies, and energy-efficient heating elements. Customers are increasingly aware of the environmental impact of their choices, and they appreciate businesses that prioritize sustainability.

In terms of consumer demands, there’s a clear expectation for high-quality and consistent results. The sandwich grill plant must be able to produce sandwiches that are not only delicious but also visually appealing. This requires precise temperature control, even heat distribution, and the ability to maintain consistent cooking times. The quality of the final product is a reflection of the brand’s commitment to excellence, and it’s a key factor in customer satisfaction.

The rise of mobile and online ordering has also changed the game for sandwich grill plants. Customers now expect seamless service, from the ability to order online to the convenience of pickup or delivery. This means that the plants need to be equipped with systems that can handle high-order volumes and integrate with various ordering platforms. The ability to process orders efficiently and maintain a high level of service is critical in meeting these new demands.

Additionally, there’s a growing trend towards technology integration. Smart appliances and digital controls are becoming more common in sandwich grill plants, allowing for better monitoring and management of the cooking process. This not only enhances the quality of the product but also improves the efficiency of the operation. The ability to analyze data and make informed decisions based on performance metrics is a valuable asset in today’s competitive market.

Lastly, the demand for flexibility in menu offerings is paramount. Sandwich grill plants must be able to quickly adapt to seasonal ingredients, limited-time promotions, and new menu items. This requires a system that can be easily modified and expanded to accommodate these changes without disrupting the workflow.

In summary, the market trends and consumer demands in the sandwich grill industry are multifaceted, encompassing the need for speed, customization, health, sustainability, quality, technology integration, and flexibility. Meeting these demands requires a high-performance sandwich grill plant that is not only technologically advanced but also adaptable to the dynamic nature of the market.

The sandwich grill plant has emerged as a cornerstone in the foodservice industry, offering numerous benefits that cater to both operational efficiency and customer satisfaction. Here’s a closer look at how it can transform a business.

Enhanced Productivity with Continuous FlowA sandwich grill plant is designed to handle high volumes of sandwiches with minimal downtime. Its continuous flow system allows for an uninterrupted production line, reducing wait times and ensuring that customers receive their orders promptly. This streamlined process not only increases output but also frees up staff to focus on other critical tasks.

Cost Savings on Energy and LaborBy utilizing efficient heating elements and optimized cooking times, sandwich grill plants can significantly reduce energy consumption. This not only lowers operational costs but also contributes to a greener, more sustainable business model. Additionally, the automation of many tasks reduces the need for excessive labor, saving on wages and benefits.

Scalability for GrowthAs businesses grow, the sandwich grill plant can scale up to meet increased demand without a proportional increase in labor or space requirements. This scalability ensures that your business can expand without sacrificing quality or efficiency, making it an attractive investment for both small startups and established chains.

Consistent Quality and PresentationMaintaining consistent quality in foodservice is paramount. The precision and uniformity of a sandwich grill plant ensure that every sandwich meets the same high standards, both in terms of taste and presentation. This consistency helps build customer loyalty and a strong brand reputation.

Flexibility in Menu OfferingsA high-performance sandwich grill plant is not limited to just sandwiches. Many models are versatile enough to cook a variety of items, such as wraps, burgers, and hot dogs. This flexibility allows businesses to adapt their menus to seasonal trends or customer preferences without the need for additional equipment.

Enhanced Customer ExperienceThe speed and efficiency of a sandwich grill plant directly impact the customer experience. By reducing wait times, customers can enjoy their meals faster, which is particularly important during peak hours. This can lead to increased foot traffic and a better overall dining experience.

Reduced Food WasteWith precise cooking controls, sandwich grill plants minimize overcooking and ensure that food is cooked to perfection. This reduces waste, which is not only environmentally friendly but also a significant cost savings for businesses.

Training and MaintenanceModern sandwich grill plants are often equipped with intuitive interfaces that make training staff easier. The simplicity of operation means that employees can quickly learn to use the equipment, reducing downtime and increasing productivity. Additionally, with regular maintenance, these machines can provide years of reliable service.

Adaptability to Different SettingsWhether you’re running a bustling café, a quick-service restaurant, or a food truck, a sandwich grill plant can fit into a variety of settings. Its compact design and modular components make it adaptable to different kitchen layouts and sizes.

Long-Term InvestmentInvesting in a sandwich grill plant is not just about immediate benefits; it’s a long-term investment in the future of your business. The reliability, efficiency, and versatility of these systems ensure that your business can thrive in an ever-changing market.

Competitive EdgeBy incorporating a high-performance sandwich grill plant into your operations, you gain a competitive edge. The speed, quality, and consistency of your product offerings can set you apart from competitors, drawing in more customers and solidifying your position in the market.

Customer Satisfaction Through ConsistencyIn the food industry, consistency is key to customer satisfaction. A sandwich grill plant ensures that every customer receives the same level of quality in their meal, which can lead to repeat business and positive word-of-mouth referrals.

Enhanced Brand ImageThe presence of a high-performance sandwich grill plant in your establishment can enhance your brand image. It signals to customers that you are committed to providing a quality dining experience, which can build trust and loyalty.

Integration with Other EquipmentThese grill plants are designed to integrate seamlessly with other kitchen equipment, such as toasters, grills, and refrigeration units. This cohesive kitchen setup ensures smooth operations and efficient workflows.

Adaptation to Dietary TrendsAs dietary preferences evolve, businesses need to adapt. A sandwich grill plant can be customized to accommodate different dietary needs, from vegetarian to gluten-free options, keeping your menu versatile and appealing to a wider audience.

Increased Turnover RateThe fast-paced nature of a sandwich grill plant can lead to an increased turnover rate, meaning more customers served in less time. This can lead to higher sales and, ultimately, higher profits.

Streamlined WorkflowThe streamlined workflow of a sandwich grill plant allows for a more organized kitchen environment. This not only improves efficiency but also reduces the risk of errors, leading to fewer wasted ingredients and increased productivity.

Customization for Special EventsFor special events or catering services, a sandwich grill plant can be a game-changer. Its ability to produce a large volume of sandwiches quickly makes it ideal for large groups, ensuring that everyone can enjoy a fresh, hot meal without delay.

Employee SatisfactionA well-organized kitchen with efficient equipment can lead to happier employees. By reducing the physical strain of manual sandwich preparation and ensuring a steady workflow, staff can feel more engaged and productive.

The Future of Sandwich PreparationInvesting in a sandwich grill plant is not just a step towards improving your current operations; it’s also a strategic move for the future. As technology continues to advance, these machines are likely to become even more efficient and versatile, ensuring that your business stays ahead of the curve.

In the bustling world of fast-casual dining, sandwich shops have become a staple, and the continuous operation sandwich grill plant has played a pivotal role in their success. Let’s dive into some real-life examples of how these innovative systems have transformed the sandwich industry.

The Urban Deli’s TransformationThe Urban Deli, a popular sandwich spot in the heart of the city, was facing challenges with their traditional sandwich grills. With long wait times and a limited capacity, the owners were searching for a solution to streamline their operation. By investing in a continuous operation sandwich grill plant, they saw an immediate boost in efficiency. The ability to grill multiple sandwiches simultaneously reduced wait times significantly, leading to happier customers and increased sales.

The Mobile Kitchen’s FlexibilityFor Mobile Kitchen, a food truck offering gourmet sandwiches on the go, flexibility was crucial. Their continuous operation sandwich grill plant allowed them to quickly and easily prepare fresh, hot sandwiches for their customers. This not only kept the line moving smoothly at food festivals and events but also enabled them to expand their menu with new offerings that required a hot grill.

The Community Cafe’s SustainabilityThe Community Cafe, a locally owned and operated eatery, placed a strong emphasis on sustainability. Their continuous operation sandwich grill plant was designed with eco-friendly features, such as energy-efficient heating elements and easy-to-clean surfaces. This commitment to sustainability not only attracted environmentally conscious customers but also helped the cafe reduce their operational costs in the long run.

The Sports Bar’s PerformanceAt the Sports Bar, where the menu revolves around quick and delicious sandwiches, the continuous operation sandwich grill plant was a game-changer. The system’s ability to maintain consistent heat and precision ensured that every sandwich was perfectly toasted and seasoned. This attention to detail improved customer satisfaction and increased repeat business for the bar.

The School Lunch Program’s EfficiencySchools across the country have adopted continuous operation sandwich grill plants to cater to large numbers of students during lunchtime. These systems can handle high volumes of sandwiches with ease, reducing the time spent on cooking and allowing school staff to focus on other aspects of meal preparation. This has led to more efficient lunch service and satisfied students who receive their meals faster.

The Catering Company’s CustomizationFor a catering company specializing in corporate events and weddings, the ability to customize sandwiches has been a significant advantage. Their continuous operation sandwich grill plant can handle a variety of fillings and toppings, allowing the company to create unique, tailored sandwiches that meet the specific preferences of their clients. This level of personalization has helped the catering company stand out in a competitive market.

The Coffee Shop’s Cross-Selling OpportunitiesA local coffee shop saw an opportunity to cross-sell their sandwiches by integrating a continuous operation sandwich grill plant into their café. The convenience of being able to serve fresh, hot sandwiches alongside their coffee and pastries attracted a wider customer base and added an extra revenue stream for the business.

The International Restaurant’s Culinary DiversityInternational restaurants often have a diverse menu that includes sandwiches from various cultures. The continuous operation sandwich grill plant has allowed these establishments to replicate the authentic flavors and textures of their traditional sandwiches, satisfying their global clientele without compromising on quality.

These case studies showcase the versatility and effectiveness of continuous operation sandwich grill plants in the sandwich industry. From urban delis to mobile kitchens, community cafes to corporate events, these systems have proven to be a valuable asset in enhancing business operations and customer experiences.

The market for sandwich grill plants is expanding rapidly, driven by the rise of fast-casual dining and the convenience of on-the-go meals. Consumers are increasingly seeking quick yet satisfying options for their lunch and dinner, and sandwich shops are stepping up their game to meet these demands. The following case studies highlight the success of sandwich grill plants in the industry.

1. The Urban Deli’s TransformationUrban Deli, a small sandwich shop in the heart of the city, struggled with high customer turnover rates due to slow service times. They invested in a high-performance sandwich grill plant, which drastically reduced preparation time. The increased efficiency led to a noticeable decrease in wait times, resulting in happier customers and a significant boost in sales.

2. The Fresh Bites Co-Op’s Community ApproachThe Fresh Bites Co-Op, a cooperative of local farmers and food artisans, integrated a continuous operation sandwich grill plant into their community café. This allowed them to offer freshly grilled sandwiches made with local, organic ingredients. The plant’s reliability ensured consistent quality, which in turn fostered a loyal customer base that appreciated the commitment to sustainability and freshness.

3. The Mobile Munchies’ Pop-Up SuccessMobile Munchies, a mobile food truck business, faced challenges with space limitations in their kitchen. By incorporating a compact, high-performance sandwich grill plant, they were able to offer a variety of sandwiches at their pop-up events. The flexibility and efficiency of the grill plant allowed them to cater to diverse tastes and increase their revenue streams.

4. The High-End Bistro’s Premium OfferingThe Bistro at the Bay, known for its upscale dining experience, introduced a gourmet sandwich menu using a state-of-the-art sandwich grill plant. The plant’s precise temperature control and even heating ensured that each gourmet sandwich was cooked to perfection. This not only enhanced the dining experience but also positioned the bistro as a leader in gourmet fast-casual dining.

5. The School Lunch Initiative’s Health ImpactA local school district implemented a sandwich grill plant in their cafeteria to provide healthy, hot sandwiches for school lunches. The plant’s ability to cook a variety of whole-grain and protein-rich sandwiches on-site contributed to a significant increase in the nutritional value of school meals. This innovative approach received praise from parents and students alike, and it set a precedent for other schools to follow.

6. The Eco-Friendly Café’s Sustainable SolutionThe Eco-Café, dedicated to eco-friendly practices, chose a sandwich grill plant that was designed with sustainability in mind. The plant used less energy and required minimal maintenance, aligning with the café’s commitment to the environment. This eco-conscious choice also resonated with the café’s customers, who appreciated the café’s efforts to reduce its carbon footprint.

These case studies illustrate the diverse ways in which sandwich grill plants have been successfully integrated into various businesses within the sandwich industry. Whether it’s increasing efficiency, enhancing quality, or promoting health and sustainability, these plants are proving to be a vital component in the quest to meet the evolving demands of today’s consumers.

The continuous operation sandwich grill plant has emerged as a game-changer in the kitchen appliance industry, offering numerous benefits that cater to both businesses and consumers. Its adoption is not just a trend but a strategic move that can significantly impact the success of a sandwich shop or café. Let’s delve into why this innovative technology is becoming a must-have for any establishment looking to excel in the sandwich market.

In the competitive world of foodservice, speed and efficiency are key. A continuous operation sandwich grill plant allows for a seamless production line, reducing wait times for customers. This means more satisfied patrons and a quicker turnover, which can lead to increased sales and revenue. The ability to produce sandwiches at a consistent rate without downtime is a compelling reason for businesses to invest in this technology.

Moreover, the plant’s ability to handle high volumes of orders without compromising on quality is a testament to its engineering prowess. The precision and reliability of these systems ensure that every sandwich meets the same high standards, maintaining brand consistency across all locations. For franchise operations, this uniformity is crucial for maintaining the integrity of the brand and customer loyalty.

The cost-effectiveness of a continuous operation sandwich grill plant cannot be overstated. While the initial investment may be higher than traditional grills, the long-term savings are substantial. The plant’s efficiency reduces energy consumption and labor costs, as fewer staff members are needed to manage the high-speed production process. This not only cuts operational expenses but also allows businesses to allocate resources more strategically.

Innovation in the sandwich industry is not just about creating new flavors; it’s also about finding ways to enhance the customer experience. The continuous operation sandwich grill plant offers a platform for creativity, allowing businesses to experiment with different cooking techniques and ingredients. This flexibility is crucial for staying ahead of the curve in a market that is constantly evolving.

Safety is another critical aspect that the continuous operation sandwich grill plant addresses. With automated systems, the risk of burns or accidents is minimized. This not only protects the employees but also ensures a safer environment for customers. The peace of mind that comes with a reduced risk of accidents can be a significant selling point for any business.

Success stories in the sandwich industry are abundant, with many operators turning to continuous operation sandwich grill plants to boost their operations. For instance, “Bite Delight,” a popular sandwich café chain, experienced a remarkable increase in sales after implementing this technology. The café’s owner, Sarah, commented, “The grill plant has transformed our business. We can serve more customers in less time, and the quality of our sandwiches has never been better.”

Another case in point is “GrillGourmet,” a high-end sandwich shop that specializes in gourmet sandwiches. The owner, Michael, noted, “The continuous operation grill plant has allowed us to offer a premium product without the premium wait times. Our customers are delighted, and our reputation for excellence has never been stronger.”

As the sandwich industry continues to grow, so does the demand for innovative solutions. The continuous operation sandwich grill plant is poised to become an industry standard, driven by the following factors:

Technology Integration: The integration of smart technology into these plants ensures that they can be monitored and controlled remotely, making them even more efficient and adaptable to changing business needs.

Health and Hygiene: With food safety being a top priority, these plants are designed to maintain the highest levels of hygiene, reducing the risk of foodborne illnesses and satisfying health code requirements.

Customization: The ability to customize the cooking process and the sandwiches themselves is a powerful tool for businesses looking to differentiate their offerings in a crowded market.

In conclusion, the continuous operation sandwich grill plant is not just a piece of equipment; it’s a strategic investment that can revolutionize the way sandwiches are made and served. Its efficiency, cost-effectiveness, and potential for innovation make it a must-have for any business aiming to thrive in the dynamic and competitive sandwich industry. As the market continues to evolve, those who embrace this technology will be well-positioned to lead the way.