Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Grill manufacturing has long been a blend of art and science, where the ability to craft not just functional but also aesthetically pleasing outdoor cooking appliances is paramount. As consumer tastes evolve and demand for unique, high-quality grills increases, the industry faces the challenge of meeting these diverse needs efficiently. This is where in-house mold making steps in, revolutionizing the way grills are produced and bringing a new level of customization and innovation to the market.

Revolutionizing Grill Production: The Power of In-House Mold Making

Grill enthusiasts and culinary professionals alike know the importance of a high-quality grill. But what goes on behind the scenes to bring these backyard marvels to life? The answer lies in the intricate world of in-house mold making, a process that is reshaping the grill production landscape. By taking control of their mold production, companies are not just crafting grills; they are crafting a new era of innovation and excellence.

In the past, grill manufacturers relied on external mold-making services, which often came with limitations. However, the advent of in-house mold making has introduced a level of customization and efficiency that was once unimaginable. This shift has become a cornerstone in the evolution of grill design and manufacturing, allowing for the creation of unique, high-performance grills that cater to the ever-growing demands of consumers.

One of the most significant advantages of in-house mold making is the enhanced flexibility it offers. With the ability to produce molds on-site, manufacturers can quickly adapt to market trends and customer preferences. This agility means that they can respond swiftly to new design requests or production changes, ensuring that their products remain at the forefront of innovation.

Quality control is another critical aspect where in-house mold making shines. By managing the mold-making process internally, companies can maintain a tight lid on the quality of the molds. This direct oversight reduces the risk of defects and inconsistencies in the final product, leading to a higher standard of grills that customers can trust.

Cost efficiency is also a major benefit of in-house mold making. Traditionally, outsourcing mold production could be a costly endeavor, with additional expenses for shipping, customs, and potential delays. By keeping mold making in-house, manufacturers can cut down on these costs, passing the savings on to their customers. This cost-effectiveness is particularly important in a competitive market where pricing can be a deciding factor for consumers.

The speed to market is another area where in-house mold making has made a significant impact. With the ability to produce molds as needed, manufacturers can reduce lead times and get their products into the hands of consumers faster. This quick turnaround time is crucial in industries where trends can shift rapidly, and being first to market can mean the difference between a successful product and one that fades into obscurity.

Innovation is at the heart of in-house mold making, and it has led to some truly novel grill designs. Companies are now able to experiment with unique shapes, materials, and features that were once impossible to achieve. From sleek, modern designs to grills that offer unparalleled cooking capabilities, the possibilities are virtually limitless.

Case studies of grill manufacturers who have embraced in-house mold making highlight the transformative power of this approach. One such example is the story of a company that transitioned from relying on external mold-making services to establishing their own in-house facility. The result was a marked increase in product quality, a reduction in lead times, and a more streamlined production process.

Industry insights reveal that market trends and consumer preferences are increasingly favoring personalized and high-quality products. In-house mold making enables manufacturers to cater to these preferences by creating custom grills that meet specific needs and desires. Whether it’s a professional-grade grill for a chef’s backyard or a compact, portable grill for a camping enthusiast, the possibilities are vast.

The role of technology in in-house mold making cannot be overstated. Advanced CAD/CAM software allows designers to create complex molds with precision, while 3D printing and rapid prototyping enable quick iterations and testing. These technological advancements have made the mold-making process more efficient and less prone to error.

In conclusion, the power of in-house mold making has revolutionized grill production. It has opened doors to new designs, improved quality control, enhanced cost efficiency, and accelerated the speed to market. As the grill industry continues to evolve, the companies that harness the full potential of in-house mold making will be the ones leading the charge into a new era of innovation and excellence.

In the world of outdoor cooking, the grill is not just a kitchen appliance; it’s an extension of culinary art. Grill design, therefore, is a blend of aesthetics, functionality, and innovation. The art of grill design has evolved over the years, reflecting the changing tastes and preferences of consumers. From the classic barbecue grills to sleek, modern gas grills, each iteration brings new features and improvements that enhance the cooking experience.

The grill design process is a meticulous one, requiring a deep understanding of materials, heat distribution, and user convenience. Designers must consider the balance between traditional elements and modern technology, ensuring that the grill not only looks good but also performs efficiently. The design phase often involves sketching out ideas, creating prototypes, and testing for durability and usability.

Grill aesthetics have become increasingly important, as consumers seek not just a cooking tool but also a statement piece for their outdoor spaces. The colors, shapes, and materials used in grill design can greatly influence the overall look and feel of a backyard or patio. Whether it’s the rustic charm of a cast iron grill or the sleek elegance of a stainless steel model, the design plays a crucial role in the product’s appeal.

Functionality is the cornerstone of any successful grill design. From the layout of the burners to the placement of the cooking grates, every detail is crucial for ensuring even heat distribution and easy cooking. The design must accommodate different cooking techniques, from grilling to smoking, and must be adaptable to various types of food. This means considering factors like the height of the cooking surface, the width of the cooking area, and the presence of features like warming racks or side burners.

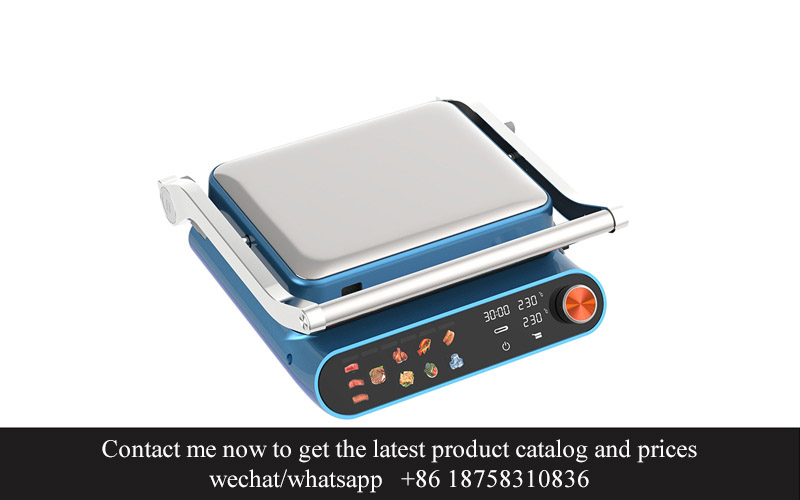

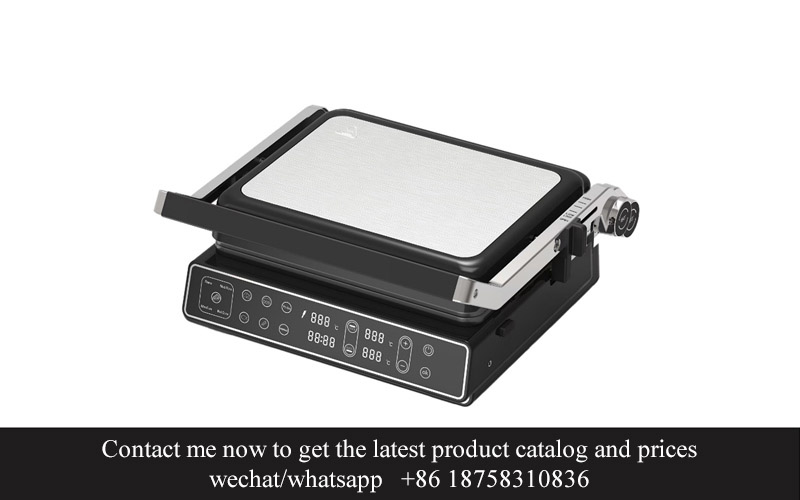

The integration of technology has also transformed grill design. Smart grills with digital temperature controls, WiFi connectivity, and app integration are becoming more common, offering users the ability to monitor and adjust their grills remotely. These technological advancements not only enhance the cooking experience but also cater to the growing trend of convenience in modern life.

In recent years, there’s been a significant emphasis on sustainability and environmental responsibility in grill design. Eco-friendly materials, energy-efficient burners, and easy-to-clean surfaces are becoming standard features. Consumers are more aware of their carbon footprint and are increasingly looking for products that align with their values.

Customization is another aspect that has gained traction in grill design. Many manufacturers offer personalized options, allowing customers to choose from various colors, finishes, and even add-ons like additional burners or unique cooking surfaces. This level of personalization not only caters to the individual preferences of consumers but also adds a unique touch to their outdoor cooking setup.

Safety is a paramount concern in grill design. Designers must ensure that all components are heat-resistant, that there are adequate safety features to prevent accidents, and that the grill is easy to use and maintain. The design must be intuitive, with clear instructions and user-friendly controls that minimize the risk of burns or fires.

Grill design is also influenced by cultural trends. For example, the popularity of Asian cuisine has led to the development of grills that are better suited for specific cooking techniques, such as searing or indirect cooking. The design must be versatile enough to accommodate these diverse culinary traditions.

Ultimately, the art of grill design is about creating a product that not only meets the practical needs of cooking but also inspires a sense of joy and community. Whether it’s through the creation of a family-friendly barbecue grill or a high-end, professional-grade model, designers are constantly pushing the boundaries of what’s possible in outdoor cooking. The result is a market brimming with creativity and innovation, offering something for every grill enthusiast.

Navigating the complexities of grill manufacturing, one of the most significant challenges lies in the realm of customization. As consumer preferences evolve and diversify, the demand for tailored grill solutions has surged. This quest for personalization, however, is not without its hurdles.

Grills come in various shapes, sizes, and functionalities, each designed to cater to specific needs and tastes. From the classic barbecue to the sleek, modern gas grill, the variety is vast. However, this diversity also translates to a complex manufacturing process that requires precision and adaptability.

The first challenge is the design phase. Grill manufacturers must constantly innovate to meet the latest design trends while ensuring that the product is both aesthetically pleasing and functional. This often involves collaborating with industrial designers who understand the nuances of material usage, ergonomics, and safety standards.

Once the design is finalized, the next challenge is in the production process. Customization demands a high degree of flexibility in manufacturing, which can be difficult to achieve. Standardization is crucial for efficiency and cost-effectiveness, but when it comes to custom orders, the ability to modify existing designs or create entirely new ones becomes paramount.

Material selection is another critical aspect. Grills are typically made from metals like stainless steel, aluminum, and cast iron, each with its own properties and challenges. Ensuring that the chosen material can be easily molded and withstand the heat and wear of outdoor use is essential. Yet, the variety of materials and finishes available can make the selection process daunting.

The precision required for custom grill manufacturing is also a challenge. Molding and shaping metal to precise specifications is a delicate process that requires advanced machinery and skilled technicians. Any error in the mold can lead to defects in the final product, which can be costly and time-consuming to rectify.

Moreover, the assembly process presents its own set of challenges. Custom grills often require intricate parts that must fit together seamlessly. This precision is crucial not just for the aesthetics but also for the grill’s performance and longevity. Ensuring that each component is correctly aligned and that the grill operates smoothly can be a complex task.

Quality control is another significant challenge. With custom orders, the stakes are high, and any flaw can lead to customer dissatisfaction. Ensuring that each grill meets the stringent quality standards is essential, but with the variety of customizations available, it can be challenging to maintain consistency across all products.

Logistics also play a role in the customization challenge. Custom orders often require a more complex supply chain management system. The need for just-in-time manufacturing and the ability to handle small batch orders efficiently can be challenging, especially for companies that are used to mass production.

Finally, the financial aspect cannot be overlooked. Customization can be expensive, both for the manufacturer and the consumer. The cost of materials, labor, and the specialized equipment required for custom grill production can be prohibitive. Balancing the need for customization with cost-effectiveness is a delicate balance that grill manufacturers must navigate.

In summary, while customization in grill manufacturing offers a wealth of opportunities to cater to diverse consumer needs, it also presents a host of challenges. From design and material selection to production, assembly, quality control, logistics, and finance, each step in the process requires careful consideration and a commitment to excellence. Only through overcoming these challenges can manufacturers deliver the high-quality, customized grills that consumers demand.

Navigating the complexities of grill manufacturing, businesses often grapple with the challenge of customization. The demand for unique designs, varied functionalities, and tailored aesthetics has surged, pushing the industry to its creative limits. However, achieving these specifications while maintaining cost-effectiveness and production efficiency is no small feat.

Customers today are not just looking for a grill; they’re seeking a statement piece that reflects their personal style and preferences. This shift in consumer behavior has introduced a new wave of challenges for manufacturers. The traditional model of mass production, where a single design is churned out in vast quantities, no longer suffices. Instead, the industry is now forced to adapt to a landscape where every grill is essentially a custom creation, albeit at a larger scale.

The challenge lies in the intricate details that define a grill’s character. Whether it’s the shape of the cooking surface, the design of the burners, or the integration of advanced features like temperature control, each aspect requires careful consideration. These nuances are what differentiate one grill from another, but they also add layers of complexity to the manufacturing process.

Designing a grill that caters to a diverse range of tastes and needs is a delicate balance between innovation and practicality. Manufacturers must innovate to stay ahead of the curve, but they also need to ensure that their products are reliable, safe, and easy to use. This dual mandate can be daunting, especially when it comes to the logistics of production.

The quest for customization often requires a high level of customization in the manufacturing process itself. From sourcing specialized materials to developing unique assembly techniques, the traditional supply chain can become a bottleneck. This is where in-house mold making steps in, offering a solution that can transform the way grills are produced.

In-house mold making allows manufacturers to create molds specifically designed for their products, eliminating the need for standard molds that may not fit their unique specifications. This capability opens the door to a world of possibilities, as it enables the production of complex grill components with precision and consistency.

One of the most significant advantages of in-house mold making is the flexibility it offers. Manufacturers can experiment with new designs and materials without the constraints of off-the-shelf molds. This freedom to innovate leads to the creation of products that stand out in the market, capturing the attention of consumers who are increasingly looking for something different.

Moreover, in-house mold making can lead to significant cost savings in the long run. By eliminating the need to purchase molds from external suppliers, businesses can reduce their upfront investment. Additionally, the ability to produce molds as needed means that there’s no excess inventory to manage, which can tie up capital and storage space.

Quality control is another area where in-house mold making shines. When molds are created and maintained within the same facility, there’s a direct line of accountability. This ensures that the molds remain accurate and in good condition, leading to consistent and high-quality products. The reduced risk of defects and the ability to quickly address any issues that arise are critical in maintaining a reputation for excellence in the grill manufacturing industry.

The speed of production is also enhanced with in-house mold making. Custom molds can be designed and produced quickly, allowing for faster turnaround times on new orders. This agility is particularly valuable in a market that is rapidly evolving and where consumers expect quick delivery of personalized products.

Furthermore, in-house mold making fosters a culture of innovation within the manufacturing process. Employees are more likely to contribute ideas and suggestions when they see the direct impact of their work on the final product. This collaborative environment can lead to breakthroughs that might not have been possible through traditional manufacturing methods.

In conclusion, the advent of in-house mold making has revolutionized the grill manufacturing industry. It has empowered businesses to embrace the challenge of customization, offering them the tools to produce high-quality, innovative grills that meet the demands of today’s discerning consumers. As the market continues to shift towards personalized and unique products, the role of in-house mold making is only expected to grow, becoming an indispensable part of the grill production process.

In-House Mold Production has emerged as a pivotal factor in the evolution of grill manufacturing. This shift towards internal mold creation offers a multitude of advantages that can significantly impact a company’s competitive edge. Let’s delve into the key benefits that in-house mold production brings to the table.

Unmatched CustomizationCrafting molds in-house allows for a level of customization that is nearly unparalleled. Manufacturers can tailor their grill designs to meet specific market demands or even individual customer requests. This flexibility ensures that the final product is not just a generic offering but a solution that resonates with the unique tastes and preferences of the target audience.

Enhanced Quality ControlWhen mold production is in-house, quality control is a seamless process. Manufacturers can oversee every stage of mold creation, from initial design to final production. This oversight ensures that the molds are not only precise but also durable, leading to consistent, high-quality grill components that can withstand the rigors of use.

Cost Efficiency Over TimeWhile investing in in-house mold making equipment may require an upfront capital investment, it can lead to long-term cost savings. By eliminating the need to outsource mold production, companies can avoid the costs associated with third-party services, such as tooling fees, shipping, and potential delays. Additionally, with consistent use, molds can maintain their precision for a longer period, reducing the frequency of replacements.

Rapid Prototyping and IterationIn-house mold production facilitates rapid prototyping, allowing manufacturers to test new designs and iterate quickly. This agility is crucial in a market where consumer preferences can shift rapidly. By being able to swiftly adapt to these changes, companies can bring innovative grill products to market more efficiently than their competitors.

Increased Speed to MarketWith in-house mold making, the production cycle can be significantly shortened. The elimination of external dependencies means that manufacturers can produce the necessary molds on demand, reducing the lead time for new product development. This speed can be a major differentiator in a competitive industry where time-to-market is a critical factor.

Reduced Dependency on External SuppliersBy having in-house mold production capabilities, companies reduce their reliance on external suppliers. This independence can be invaluable, especially in times of supply chain disruptions. It ensures that production continues smoothly, even when external factors might otherwise cause delays or shortages.

Innovation and Design FlexibilityIn-house mold making empowers designers to push the boundaries of innovation. The ability to create complex and unique molds enables the development of grill designs that might not be feasible with standard, off-the-shelf molds. This flexibility can lead to groundbreaking products that stand out in a crowded marketplace.

Improved SustainabilityIn-house mold production can also contribute to a company’s sustainability efforts. By reducing the need for shipping molds from one location to another, manufacturers can decrease their carbon footprint. Additionally, the ability to repair and recondition molds in-house can further extend their lifespan, aligning with environmental sustainability goals.

Data-Driven DecisionsWith in-house mold making, manufacturers can gather valuable data throughout the production process. This data can be used to make informed decisions about design improvements, material choices, and manufacturing processes, leading to a continuous cycle of innovation and optimization.

Long-Term Strategic AdvantagePerhaps most importantly, in-house mold production can provide a long-term strategic advantage. Companies that invest in this capability are better positioned to respond to market changes, meet customer expectations, and lead the way in grill manufacturing innovation.

In conclusion, the benefits of in-house mold production are multifaceted, offering manufacturers a competitive edge in terms of customization, quality, cost, speed, and innovation. As the grill market continues to evolve, those who embrace in-house mold making are likely to be at the forefront of this dynamic industry.

In-house mold making has become a cornerstone in the evolution of grill design, allowing manufacturers to push the boundaries of innovation and cater to the ever-changing demands of consumers. This process has several key advantages that have revolutionized how grills are conceptualized, produced, and received in the market.

Grill manufacturers often face the challenge of creating unique designs that stand out in a crowded marketplace. In the past, this required outsourcing mold production to specialized mold-making companies, which could be a lengthy and costly process. However, with in-house mold making, designers have the freedom to experiment with new shapes, sizes, and features without the constraints of external production timelines and budgets.

Customization is at the heart of in-house mold making’s appeal. Designers can quickly iterate on prototypes, making adjustments in real-time based on feedback and testing. This agility allows for the creation of grills that are not only visually appealing but also functional and tailored to the specific needs of the end-user. For instance, a manufacturer might develop a grill with a unique heat distribution system, a more ergonomic handle, or a modular design that allows for additional accessories to be attached.

One of the most significant benefits of in-house mold making is the quality control it offers. When the same company designs, manufactures, and tests the molds, there’s a direct line of accountability. This means that any issues with the mold design or the finished product can be addressed immediately, ensuring that each grill meets the highest standards of quality. It also means that manufacturers can respond swiftly to any recalls or repairs, which is critical in maintaining a strong brand reputation.

Cost efficiency is another crucial aspect of in-house mold making. While setting up an in-house mold-making capability requires an initial investment, it can lead to long-term savings. By eliminating the need for external mold-making services, manufacturers can reduce overhead costs associated with outsourcing. Additionally, the ability to produce multiple molds simultaneously can increase output and reduce the unit cost of each mold, making it more economical for high-volume production runs.

The speed of production is also significantly improved with in-house mold making. Traditional mold-making processes can take weeks or even months, delaying the time it takes to bring a new grill design to market. With in-house capabilities, these timelines can be drastically reduced, allowing manufacturers to respond more quickly to market trends and consumer demands. This agility is particularly important in the fast-paced grill industry, where new features and designs can quickly become obsolete.

Innovation thrives in an environment where there’s a culture of continuous improvement. In-house mold making fosters this culture by enabling designers and engineers to test and refine their ideas in a controlled setting. This iterative process can lead to breakthroughs in grill design, such as the integration of smart technology for monitoring temperature and cooking times, or the development of eco-friendly materials that reduce the grill’s carbon footprint.

One of the most compelling aspects of in-house mold making is its ability to create limited edition or specialty grills. For instance, a manufacturer might collaborate with a celebrity chef to design a custom grill that reflects the chef’s culinary philosophy. These unique pieces can serve as a marketing tool, driving interest and demand, while also adding a sense of exclusivity to the product line.

The rise of in-house mold making has also led to a more collaborative approach within manufacturing companies. Designers, engineers, and production teams work closely together throughout the mold-making and production process. This collaboration breaks down silos and encourages a holistic view of product development, ensuring that every aspect of the grill is optimized for performance, aesthetics, and user experience.

The benefits of in-house mold making extend beyond the grill itself. It has a ripple effect on the entire supply chain. By having control over the mold-making process, manufacturers can ensure that the materials used are of the highest quality and that the production process is as efficient as possible. This not only reduces waste but also improves the sustainability of the products.

In conclusion, in-house mold making has become a powerful tool for grill manufacturers looking to innovate and differentiate themselves in a competitive market. The ability to customize, control quality, reduce costs, increase speed, and foster a culture of innovation has opened up new possibilities for grill design and production. As the industry continues to evolve, in-house mold making is poised to play an even more pivotal role in shaping the future of outdoor cooking.

In the realm of grill manufacturing, technology has become an indispensable tool, reshaping the way molds are made and the end products they produce. The integration of advanced tech into in-house mold making has revolutionized the industry, offering a multitude of benefits that were once unimaginable.

Precision Engineering at Its FinestThe precision required for high-quality grill molds is unmatched. Technology has enabled manufacturers to create molds with intricate details and seamless finishes, ensuring that every grill component fits perfectly. CNC machines, for instance, have replaced the traditional hand-crafted molds, allowing for exact measurements and repeated consistency that manual labor simply cannot match.

Streamlined Production ProcessesBy incorporating technology into the mold-making process, grill manufacturers have seen a significant reduction in production times. Automation has taken over many of the repetitive tasks, from designing the mold to its final shaping, allowing for a more efficient workflow. This streamlined process means that manufacturers can produce a larger quantity of high-quality grills in a shorter amount of time.

Enhanced Design CapabilitiesThe role of technology in in-house mold making extends to the design phase. Advanced software like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) has empowered designers to visualize and create complex grill designs with ease. These tools offer the ability to simulate and test designs before they are even made into molds, reducing the risk of costly mistakes and allowing for rapid prototyping.

Customization and PersonalizationTechnology has also opened the door to customization and personalization in grill design. With the ability to create molds that are tailored to specific requirements, manufacturers can cater to niche markets and individual preferences. Whether it’s a unique shape, size, or material, the possibilities are endless, thanks to the precision and adaptability of modern mold-making technology.

Improved Quality ControlOne of the most significant benefits of technology in in-house mold making is the improvement in quality control. Advanced sensors and scanning technologies can detect even the smallest imperfections in the molds, ensuring that the final products meet the highest standards. This level of quality assurance is crucial in maintaining a brand’s reputation and customer satisfaction.

Cost-Effective ProductionWhile the initial investment in technology can be substantial, the long-term benefits often outweigh the costs. By reducing the need for manual labor, minimizing errors, and increasing production speed, technology-driven mold making can lead to significant cost savings. Moreover, the ability to produce more with less means that manufacturers can reduce their inventory costs and improve their overall financial health.

Collaboration and CommunicationModern technology has also enhanced collaboration within the mold-making process. Designers, engineers, and production teams can work together seamlessly using digital platforms, sharing ideas and feedback in real-time. This collaborative environment fosters innovation and ensures that the mold-making process is efficient and aligned with the company’s goals.

Adaptability to Market TrendsThe grill industry is constantly evolving, and technology allows mold makers to stay ahead of the curve. With the ability to quickly adapt molds to new market trends and consumer demands, manufacturers can respond to changes swiftly. This agility is crucial in a competitive market where innovation is key to staying relevant.

Sustainability and Environmental ImpactLastly, technology in in-house mold making has contributed to a more sustainable approach to production. By reducing waste, optimizing materials, and decreasing energy consumption, manufacturers are not only cutting costs but also reducing their environmental footprint. This commitment to sustainability is becoming increasingly important to consumers and can be a major selling point for grill manufacturers.

In conclusion, the role of technology in in-house mold making has transformed the grill manufacturing industry. From precision engineering to cost-effective production, the benefits are clear. As technology continues to advance, the possibilities for innovation and efficiency in grill design and manufacturing will only grow, ensuring that the grill industry remains at the forefront of innovation and consumer satisfaction.

In the ever-evolving landscape of the grill manufacturing industry, understanding market trends and consumer preferences is crucial for staying competitive. Here’s a glimpse into the latest insights:

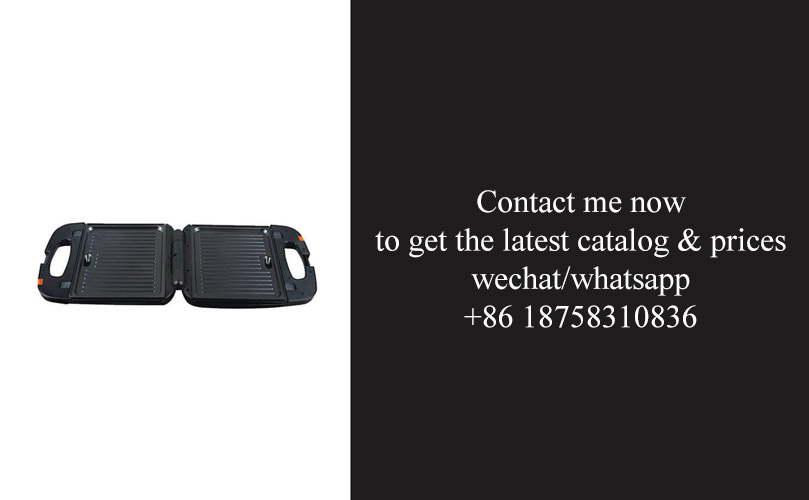

The demand for versatile and efficient grills continues to rise, driven by consumers seeking not just a cooking tool but an all-in-one outdoor kitchen experience. Compact, multi-functional grills are becoming increasingly popular, as they cater to the needs of urban dwellers with limited space.

Smart technology integration is another significant trend. Grills with Bluetooth connectivity, temperature control apps, and built-in timers are appealing to tech-savvy consumers looking for convenience and precision in their grilling adventures. These features not only enhance the cooking experience but also cater to the desire for smart home integration.

Eco-conscious consumers are also driving the market. There’s a growing preference for grills made from sustainable materials and with energy-efficient designs. This shift reflects a broader environmental awareness and a willingness to invest in products that align with green values.

Health and wellness are at the forefront of consumer preferences, too. Grills that promote healthier cooking methods, such as those that minimize smoke and charred food, are gaining traction. Consumers are increasingly interested in grills that offer healthier alternatives to traditional cooking methods.

The rise of outdoor dining and entertaining has led to a surge in demand for high-end, luxury grills. These premium models often come with customizable features, superior craftsmanship, and innovative design elements that appeal to those who value quality and style.

In terms of design, sleeker, modern aesthetics are preferred over the traditional, rustic look. Consumers are gravitating towards grills that blend seamlessly into their outdoor spaces, offering a clean, contemporary look that complements their gardens, patios, and balconies.

The market is also witnessing a trend towards personalized grilling solutions. Customization options, such as adjustable burners, interchangeable cooking grids, and unique grill designs, are becoming more accessible, allowing consumers to tailor their grills to their specific needs and preferences.

As the industry adapts to these trends, it’s clear that understanding the evolving landscape is key to meeting consumer expectations. By staying attuned to these market insights, grill manufacturers can continue to innovate and offer products that resonate with today’s consumers.

In a bustling industrial park, a small yet innovative grill manufacturer has turned heads with their in-house mold making capabilities. This case study delves into the success story of how a commitment to custom molds has reshaped their product line and market presence.

The company, known for its sleek, high-quality grills, faced a common challenge in the industry: the need for specialized molds to create unique and intricate designs. Traditionally, these molds were sourced externally, which often led to delays and limited design options. However, the decision to invest in in-house mold making changed everything.

The process began with a thorough analysis of their existing product line. They identified several key areas where customization could enhance their grills’ appeal. This included everything from the shape of the grill grates to the design of the handles and the structure of the burners.

With the company’s engineers and designers at the helm, they embarked on a journey to create molds that would allow them to produce these new features in-house. The initial phase involved extensive research and development, leveraging the latest 3D modeling software to visualize the desired designs.

The team faced several hurdles along the way. There was a steep learning curve with new machinery and techniques, and the precision required for mold making was incredibly demanding. However, their passion for innovation and quality drove them forward.

Once the molds were designed, the real work began. The company invested in state-of-the-art CNC machines, which could cut complex shapes with precision. The molds were crafted with attention to detail, ensuring that the final product would meet their stringent quality standards.

The results were nothing short of remarkable. The new grills, with their custom-designed grates and innovative features, were a hit with consumers. The company saw an increase in sales and a surge in positive feedback, with customers praising the unique design and exceptional build quality.

But the benefits didn’t stop there. By having in-house mold making capabilities, the company gained several advantages. They could now respond quickly to market demands, introducing new products at a moment’s notice. This agility allowed them to stay ahead of competitors who were still reliant on external mold suppliers.

Moreover, the cost savings were substantial. With external mold suppliers, there were often hidden costs such as long lead times and non-disclosure agreements. By bringing mold making in-house, the company eliminated these expenses and was able to allocate resources more efficiently.

The project also had a significant impact on the company’s culture. Employees felt a sense of pride in their ability to contribute to such a successful initiative. The success of the in-house mold making project fostered a collaborative environment where innovation was celebrated and encouraged.

As the project matured, the company began to explore additional applications for their custom molds. They started experimenting with different materials and finishes, offering a wider range of options to their customers. This diversification further solidified their position as a leader in the grill market.

The success of this in-house mold making project is a testament to the power of innovation and the willingness to embrace change. It’s a story of a company that took a chance on themselves, investing in their own capabilities and reaping the rewards. The project has not only enhanced their product offerings but has also positioned them as a forward-thinking manufacturer in the competitive grill industry.

The grill manufacturing industry is on the cusp of a transformative era, driven by advancements in technology and a shift towards customized consumer experiences. As we stand at the forefront of this revolution, it’s clear that the future holds immense potential for innovation and growth. From the adoption of in-house mold making to the integration of cutting-edge technologies, the landscape of grill manufacturing is evolving rapidly. This conclusion aims to encapsulate the key developments shaping the future of this dynamic sector, highlighting the path forward and the opportunities that lie ahead.

Grill manufacturers are increasingly recognizing the value of in-house mold making capabilities. By bringing the mold production process in-house, companies can respond more swiftly to market demands, reduce lead times, and maintain higher quality control over their products. This shift allows for a more agile approach to design and production, ensuring that grills are not only functional but also meet the evolving tastes and preferences of consumers.

The integration of advanced technologies such as 3D printing and computer-aided design (CAD) has further revolutionized the grill manufacturing process. These technologies enable designers to create complex and unique grill designs with precision and efficiency. The ability to prototype and iterate quickly means that manufacturers can bring innovative products to market faster, staying ahead of the competition and satisfying the demands of a tech-savvy consumer base.

Market trends indicate a growing preference for smart and eco-friendly grills. Consumers are looking for appliances that not only enhance their cooking experience but also align with their values regarding sustainability and convenience. This shift is prompting grill manufacturers to invest in research and development, focusing on energy-efficient designs and smart features that can be controlled remotely or through voice commands.

One significant trend is the rise of modular grill designs. These allow consumers to customize their grills by adding or removing components based on their specific needs. This modular approach not only caters to a wider range of preferences but also opens up new revenue streams for manufacturers through the sale of additional accessories and upgrades.

Another area of innovation is the use of high-performance materials. Materials like stainless steel and advanced alloys are being used to create grills that are not only durable but also resistant to corrosion and heat. These materials not only extend the lifespan of the grill but also contribute to its aesthetic appeal.

The global grill market is also witnessing a surge in demand from emerging markets. As these regions experience economic growth and urbanization, there is a corresponding increase in the number of consumers looking to purchase grills for their homes. This presents an opportunity for grill manufacturers to expand their reach and cater to a diverse set of consumer needs.

However, along with these opportunities come challenges. The need for continuous innovation and the pressure to keep up with market trends can be daunting. Manufacturers must balance the desire to introduce new products with the need to maintain profitability. Additionally, the complexity of managing global supply chains and navigating trade policies can pose significant hurdles.

In the future, grill manufacturing will likely see a greater emphasis on sustainability. As environmental concerns become more prevalent, manufacturers will be under pressure to reduce their carbon footprint and adopt greener production practices. This could involve sourcing materials from sustainable sources, improving energy efficiency in production facilities, and designing products that are easier to recycle or dispose of responsibly.

The future of grill manufacturing also hinges on the ability to adapt to changing consumer preferences. This means staying abreast of the latest culinary trends and incorporating them into grill designs. For instance, the popularity of outdoor cooking and entertaining has led to a demand for grills that offer more than just heat – they must also serve as stylish focal points for social gatherings.

In conclusion, the future of grill manufacturing is bright, filled with opportunities for innovation and growth. By embracing in-house mold making, leveraging technology, and staying attuned to market trends and consumer preferences, manufacturers can navigate the challenges ahead and continue to produce high-quality, innovative grills that captivate the hearts and palates of consumers worldwide.