Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, one trend has been particularly transformative: the air fryer. With its promise of healthier cooking and convenience, this appliance has become a staple in many homes across the globe. As the market for air fryers continues to grow, understanding the intricacies of the OEM (Original Equipment Manufacturer) process, especially when it comes to turnkey solutions with UL certification, is crucial for brands looking to thrive in this dynamic sector. This article delves into the significance of turnkey solutions in the OEM landscape, offering insights into how they can pave the way for sustainable growth and success.

The air fryer market has experienced a remarkable surge in popularity across the Western world, transforming the landscape of kitchen appliances. Once a niche product, these countertop wonders have now become a staple in many homes, offering a healthier alternative to traditional frying methods. The shift towards healthier lifestyles, coupled with technological advancements, has propelled the air fryer industry to new heights.

As health-conscious consumers seek out cooking methods that reduce oil content while maintaining flavor, air fryers have stepped into the spotlight. The allure of crispy, golden-brown foods with minimal oil has captivated the palates of both health enthusiasts and culinary adventurers alike. Supermarkets and specialty stores are now brimming with an array of air fryer models, each promising to elevate the cooking experience.

The convenience factor cannot be overstated. Air fryers are compact, easy to use, and require minimal cleanup. They’ve become a go-to kitchen gadget for busy professionals, families, and anyone looking to streamline their cooking routine. The versatility of air fryers extends beyond French fries and chicken wings, with users experimenting with everything from vegetables to desserts.

The rise of social media and food blogs has also played a significant role in the air fryer’s meteoric rise. Influencers and chefs have showcased the myriad possibilities of air frying, turning it into a trend that’s hard to ignore. The hashtag #airfryerrecipes has amassed a,as home cooks share their creative recipes and cooking tips.

From a commercial standpoint, the Western market’s embrace of air fryers has been a goldmine for manufacturers. Companies have responded by launching innovative models with features like programmable settings, smart technology integration, and even eco-friendly materials. The competition has spurred innovation, leading to air fryers that cater to a wide range of cooking preferences and dietary needs.

Moreover, the health benefits of air frying have been a key driver in its popularity. Air fryers use hot air to circulate around the food, creating a crispy outer layer while reducing the amount of oil needed. This not only makes the food healthier but also cuts down on calories and fats. As people become more aware of the impact of their diets on their health, air fryers have positioned themselves as a convenient and responsible choice.

The Western world’s love affair with air fryers is also influenced by the broader trend of home cooking. With the closure of restaurants and dining establishments due to various factors, including the COVID-19 pandemic, more people are turning to home cooking as a way to save money and enjoy quality meals. Air fryers fit perfectly into this trend, offering a way to prepare delicious, homemade food without the need for deep-fat frying.

The market’s growth has not gone unnoticed by investors and entrepreneurs. Startups are popping up, offering unique air fryer models and accessories, while established appliance brands are investing heavily in research and development to keep up with consumer demand. The result is a dynamic market that is constantly evolving, with new features and designs being introduced regularly.

In conclusion, the air fryer market’s rise in the Western world is a testament to the power of innovation, health consciousness, and convenience. As the trend continues to gain momentum, it’s clear that air fryers are here to stay, reshaping the way we cook and eat.

In the ever-evolving OEM (Original Equipment Manufacturer) landscape, the demand for comprehensive turnkey solutions has surged. These solutions have become a cornerstone for companies looking to streamline their manufacturing processes, reduce costs, and meet the stringent requirements of the global market. Let’s delve into why turnkey solutions are not just important, but crucial for OEMs.

The first benefit of turnkey solutions is the elimination of the need for in-house expertise. OEMs often lack the specialized knowledge required to design, engineer, and produce complex products. By partnering with a turnkey provider, these companies can leverage the extensive experience and technical know-how of their partners. This collaboration ensures that every aspect of the product development cycle is handled by experts, from initial design to final manufacturing.

Another critical aspect is the acceleration of time-to-market. In today’s fast-paced market, speed is of the essence. Turnkey solutions are tailored to be efficient, reducing the time it takes to bring a product from concept to completion. This rapid deployment allows OEMs to stay ahead of competitors and meet the ever-changing demands of consumers.

Quality control is paramount in the OEM industry, and turnkey solutions offer a robust framework to ensure high standards are maintained. With turnkey providers, OEMs gain access to rigorous quality assurance processes that are integrated into every stage of production. This not only guarantees that the final product meets industry standards but also builds trust with end-users.

Cost savings are a significant draw for OEMs seeking turnkey solutions. By outsourcing the manufacturing process, companies can avoid the substantial upfront investment required to establish and maintain their own production facilities. This includes the costs of purchasing equipment, training staff, and maintaining inventory. Turnkey providers often operate on a scale that allows for cost optimization, passing on savings to their clients.

Customization is another area where turnkey solutions shine. OEMs can work closely with turnkey partners to create products that are uniquely tailored to their target market. This level of flexibility allows for the development of niche products that can differentiate a brand in a crowded marketplace.

Supply chain management is a complex and challenging aspect of the OEM landscape. Turnkey solutions offer a streamlined approach to managing the supply chain, from sourcing raw materials to logistics and distribution. This comprehensive management ensures that OEMs have a reliable and efficient supply chain that can adapt to changes in demand and market conditions.

Moreover, turnkey solutions provide a safety net for compliance with international regulations. As regulations vary by country and industry, staying compliant can be daunting. Turnkey providers are well-versed in these regulations and ensure that every product meets the necessary standards, reducing the risk of legal issues for their clients.

Innovation is a driving force in the OEM sector, and turnkey solutions foster a culture of creativity. By partnering with a turnkey provider, OEMs can tap into the latest technological advancements and design trends. This collaboration can lead to the creation of cutting-edge products that stand out in the market.

Lastly, the scalability of turnkey solutions is a game-changer for OEMs. As demand fluctuates, the ability to scale up or down production is essential. Turnkey providers are equipped to handle varying production volumes, ensuring that OEMs can respond quickly to market shifts without the constraints of fixed capacity.

In conclusion, the importance of turnkey solutions in the OEM landscape cannot be overstated. From expertise and speed to quality, cost savings, customization, supply chain management, compliance, innovation, and scalability, turnkey solutions are a comprehensive answer to the challenges faced by OEMs in the modern marketplace. By embracing these solutions, companies can focus on their core competencies and leave the complexities of manufacturing to the experts.

In the ever-evolving landscape of the Original Equipment Manufacturer (OEM) industry, the significance of UL certification cannot be overstated. This globally recognized safety standard is not just a regulatory requirement; it’s a cornerstone for credibility and trust among consumers and industry peers alike.

The stringent criteria set by Underwriters Laboratories (UL) ensure that products meet or exceed safety, performance, and quality benchmarks. For OEMs looking to enter new markets, especially in the United States and Canada, UL certification is a gateway to consumer confidence and compliance with local regulations.

One of the primary reasons UL certification is crucial is the assurance it provides to customers. When a product carries the UL mark, it signifies that it has been tested and deemed safe for use. This is particularly important in the highly competitive kitchen appliance market, where safety is a paramount concern. Consumers are more likely to purchase a product that has been vetted by a respected third-party organization like UL.

Moreover, UL certification is not just about safety; it’s also about quality control. The certification process involves a thorough examination of the manufacturing process, from raw materials to final assembly. This ensures that the OEM is producing a high-quality product that will stand the test of time and use.

In the OEM landscape, where brands rely on manufacturers to deliver products that align with their brand identity, UL certification becomes a critical differentiator. It allows OEMs to showcase their commitment to excellence and innovation, which can be a deciding factor in securing contracts with retailers and distributors.

The certification process also fosters a culture of continuous improvement within the OEM. By adhering to the stringent UL standards, manufacturers are encouraged to invest in better materials, more efficient production techniques, and cutting-edge design solutions. This not only benefits the end-user but also enhances the reputation of the OEM as a leader in their field.

For international OEMs looking to expand their reach into new markets, UL certification is a key component of their strategy. It can be challenging to navigate the various regulatory requirements of different countries, but having a UL mark on a product simplifies the process. It signals to local authorities that the product meets the necessary safety standards, which can expedite the approval process and reduce the time to market.

In the case of air fryers, a popular and rapidly growing segment within the kitchen appliance market, UL certification is particularly vital. As these devices become more prevalent in homes, the potential for accidents or malfunctions increases. Having the UL certification reassures customers that the air fryer they are purchasing is safe, reducing the risk of liability for the OEM.

Furthermore, UL certification can open doors to new business opportunities. Many retailers and distributors require products to carry the UL mark before they will consider them for their shelves. This can be a significant barrier for manufacturers without certification, but for those who have it, it’s a competitive advantage.

Lastly, the certification process itself can be a learning experience for OEMs. It forces them to examine every aspect of their product and process, from design to distribution. This comprehensive review can lead to valuable insights and improvements that can be applied to future products and operations.

In conclusion, UL certification is not just a regulatory box to tick; it’s a testament to the commitment of an OEM to safety, quality, and innovation. In an industry where trust is paramount, having the UL mark on a product can make all the difference in the marketplace.

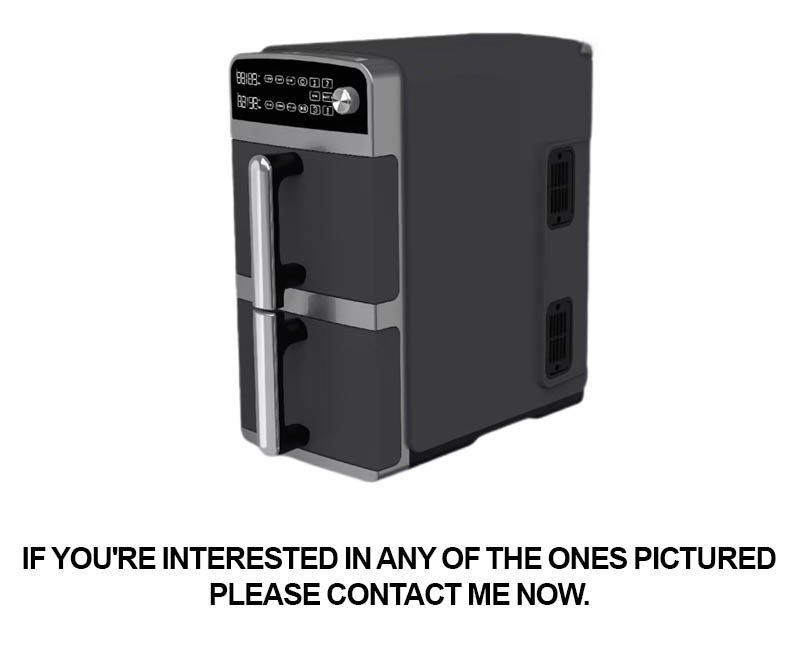

In the ever-evolving landscape of kitchen appliances, the air fryer has emerged as a game-changer, offering a healthier alternative to traditional frying methods. As consumers become more health-conscious, innovative designs in air fryers are not just a trend—they’re a glimpse into the future of cooking. Here’s a closer look at some of the latest and most innovative air fryer designs that are shaping the market:

The sleek, compact design of modern air fryers is a testament to the industry’s commitment to space-saving solutions. These appliances are designed to fit seamlessly into any kitchen, from tiny apartments to expansive kitchens. The streamlined look, often with a glossy finish, not only adds a touch of modern elegance but also ensures that the air fryer is a centerpiece rather than an eyesore.

Intuitive Touchscreens and Smart TechnologyOne of the most significant advancements in air fryer design is the integration of intuitive touchscreens and smart technology. These screens allow users to easily select pre-programmed settings for a variety of foods, from crispy French fries to succulent chicken wings. Smart features like Wi-Fi connectivity and remote control capabilities mean users can start their cooking before they even step into the kitchen, adjusting settings from their smartphone or tablet.

Air Fryer Convection OvensThe traditional air fryer has evolved into a multi-functional appliance with the introduction of convection ovens. These units combine the hot air circulation of an air fryer with the convection heating of an oven, allowing for a more even cooking process and a wider range of recipes. Users can now bake, roast, and even dehydrate with the same appliance that provides the benefits of air frying.

Self-Cleaning and Easy-to-Clean FeaturesOne of the biggest hurdles for any kitchen appliance is the cleaning process. Air fryer manufacturers have tackled this challenge head-on with self-cleaning and easy-to-clean features. Some models use high heat to burn off excess oil, while others have non-stick interiors that make for a quick wipe-down. This not only saves time but also ensures that the appliance remains hygienic and ready for use at a moment’s notice.

Personalized Cooking ExperienceInnovative air fryer designs are also focusing on creating a more personalized cooking experience. Features like adjustable temperature controls and cooking time settings allow users to tailor their cooking to their specific preferences. Some models even offer a “flip” function, which ensures that food is cooked evenly on both sides, eliminating the need for manual flipping.

Designs for Health and SafetySafety and health are paramount in kitchen appliance design, and air fryers are no exception. Modern air fryers are equipped with safety features like automatic shut-off, which turns off the appliance if it’s left unattended or if the cooking chamber is opened during operation. Additionally, the use of high-quality materials and BPA-free components ensures that users can enjoy their meals without any health concerns.

Customizable AccessoriesTo cater to a wide range of cooking styles and preferences, manufacturers are offering customizable accessories with their air fryers. These can include different baskets, racks, and inserts that allow for various cooking techniques, such as roasting, grilling, or even making desserts. This versatility turns the air fryer into a multipurpose tool that can replace several other appliances in the kitchen.

Interactive Cooking ExperienceThe future of air fryer design is not just about the appliance itself but also about the experience it provides. Some brands are integrating interactive features that allow users to follow along with cooking tutorials, share recipes, and even connect with a community of fellow cooks. This interactive element turns the air fryer into a hub for culinary exploration and connection.

In conclusion, the innovative air fryer designs we’re seeing today are not just a response to consumer demand for healthier cooking options; they’re a peek into the future of kitchen appliances. As technology continues to advance, we can expect even more sophisticated features that make cooking not only healthier but also more enjoyable and convenient.

Understanding the OEM process can be a complex journey, especially for those new to the world of manufacturing. It involves collaboration, innovation, and a clear understanding of the client’s needs. Here’s a step-by-step guide to help navigate the OEM process effectively:

Identify Your Product Vision: Before diving into the OEM process, it’s crucial to have a clear vision of the product you want to develop. This includes understanding your target market, identifying the problem your product solves, and envisioning its features and design.

Research Potential OEM Partners: Once you have a product vision, it’s time to research and identify potential OEM partners. Look for manufacturers with a strong track record in your industry, a reputation for quality, and the capacity to handle your project’s scale.

Evaluate Capabilities and Compatibility: When considering OEM partners, assess their capabilities to ensure they can meet your specific requirements. This includes evaluating their production capacity, technology, quality control processes, and any certifications they hold.

Initiate Contact and Discuss Requirements: Reach out to your top choices and initiate discussions. Clearly communicate your product requirements, design specifications, expected timelines, and any other pertinent details. This is where transparency is key to establish a solid foundation for the partnership.

Review and Finalize the NDA: Before sharing sensitive information, ensure both parties sign a Non-Disclosure Agreement (NDA) to protect intellectual property and proprietary information.

Collaborate on Design and Prototyping: Work closely with your OEM partner to refine the design. This stage often involves multiple iterations to achieve the desired product. Be prepared to provide feedback and make adjustments as needed.

Quality Assurance and Testing: Once the prototype is ready, it’s essential to conduct thorough quality assurance and testing. This ensures the product meets all safety standards and performs as expected. The OEM should have robust testing protocols in place.

Scale Production: Once the design is finalized and the product passes all tests, it’s time to scale production. This involves coordinating with the OEM on production timelines, material sourcing, and logistics.

Manage Supply Chain and Logistics: The OEM process requires careful management of the supply chain and logistics. This includes overseeing the procurement of raw materials, managing inventory, and coordinating shipping to ensure products are delivered on time.

Quality Control During Production: Even with a robust testing process, it’s crucial to maintain quality control throughout the production cycle. Regular audits and inspections can help catch any issues early on.

Final Product Inspection and Quality Control: Before shipping, conduct a final inspection to ensure that every product meets the agreed-upon standards. This is a critical step to avoid any defects reaching the end consumer.

Logistics and Distribution: Coordinate with the OEM to manage the logistics of shipping your products to the warehouse or directly to customers. This may involve working with third-party logistics providers to ensure efficient delivery.

Post-Launch Support: Once the product is in the market, continue to support your customers and the OEM. This includes handling any warranty claims, customer service issues, or product updates.

Evaluate and Refine: After the product launch, gather feedback from both customers and the OEM to evaluate the partnership’s success. Look for areas of improvement and consider how you can refine the product or the OEM relationship for future projects.

Plan for Continuous Improvement: The OEM process is not a one-time event but an ongoing relationship. Plan for continuous improvement by staying abreast of market trends, technological advancements, and customer needs. This will help you maintain a competitive edge and ensure long-term success.

Partnering with a turnkey UL certified air fryer OEM can offer a multitude of benefits that can significantly enhance your product development and market presence. Here’s a deeper look into some of these advantages:

Streamlined Product Development– By collaborating with a turnkey OEM, you gain access to a team of experts who specialize in air fryer design and manufacturing. This collaboration ensures that your product development process is efficient and focused, allowing you to bring a high-quality air fryer to market quickly.

Quality Assurance and Compliance– A turnkey UL certified air fryer OEM is committed to maintaining the highest standards of quality and safety. This means that every aspect of the manufacturing process adheres to rigorous industry regulations, ensuring that your product meets or exceeds the necessary safety standards for market entry.

Cost-Effective Production– Working with a turnkey OEM can be more cost-effective than establishing your own manufacturing facility. These companies often operate on a large scale, which can lead to economies of scale in terms of materials, labor, and production processes, ultimately reducing your overall costs.

Customization and Flexibility– Turnkey OEMs typically offer a high degree of customization, allowing you to tailor the air fryer to your brand’s specifications. This flexibility can be crucial for differentiating your product in a crowded market and meeting the unique needs of your target audience.

Access to Advanced Technology– Turnkey OEMs are often at the forefront of technological advancements in the air fryer industry. This means you can leverage cutting-edge features and innovations in your product, giving it a competitive edge and enhancing its appeal to consumers.

Reduced Risk and Liability– When you work with a turnkey OEM, you share the risk and liability associated with the manufacturing process. This can provide peace of mind, as the OEM is responsible for ensuring that the product meets all safety and quality standards, thereby minimizing your legal and financial risks.

Global Supply Chain Expertise– Turnkey OEMs have established relationships with suppliers around the world, allowing them to source materials and components at competitive prices. This global reach can also ensure a reliable and efficient supply chain, reducing the risk of delays and disruptions.

Marketing and Sales Support– Many turnkey OEMs offer additional support services, such as marketing assistance and sales coordination. This can be particularly valuable if you’re new to the air fryer market or if you’re looking to expand your reach into new territories.

Continuous Improvement and Innovation– Turnkey OEMs are constantly seeking ways to improve their products and processes. This means that you benefit from ongoing innovation and the ability to adapt to changing market trends and consumer preferences.

Enhanced Brand Image– By associating your brand with a turnkey UL certified air fryer OEM, you can enhance your brand image. Consumers often perceive products that come with certifications as being safer and more reliable, which can boost customer confidence and trust.

Focus on Core Competencies– When you outsource the manufacturing of your air fryers to a turnkey OEM, you can focus on your core competencies, such as product design, marketing, and customer service. This strategic decision can lead to more efficient operations and a clearer competitive advantage.

Scalability– As your business grows, a turnkey OEM can scale production to meet increased demand. This scalability is crucial for maintaining inventory levels and meeting customer expectations without overextending your own resources.

Environmental Responsibility– Many turnkey OEMs are committed to sustainable practices and environmental responsibility. By partnering with such a company, you can align your brand with eco-friendly initiatives, which is increasingly important to environmentally conscious consumers.

In summary, partnering with a turnkey UL certified air fryer OEM can provide a comprehensive range of benefits that support your brand’s growth and success. From quality assurance and cost savings to customization and access to advanced technology, the strategic partnership can be a game-changer in the competitive landscape of kitchen appliances.

In the world of kitchen appliances, partnering with a turnkey solution provider can be a game-changer for brands. Let’s delve into some success stories that showcase how brands have thrived by trusting turnkey solutions.

Branding Powerhouse Boosts Market PresenceOne major brand, known for its sleek and modern kitchen appliances, decided to take a leap of faith with a turnkey solution for their new air fryer line. By collaborating with a turnkey OEM that offered not just manufacturing but also design, certification, and distribution, the brand was able to hit the market with a product that perfectly aligned with their brand identity. The turnkey approach streamlined the process, allowing the brand to focus on marketing and customer engagement, rather than getting bogged down in the complexities of production.

Local Cuisine on a Global ScaleA small startup with a passion for local cuisine wanted to introduce their unique air fryer recipe kits to a wider audience. They turned to a turnkey OEM that provided a full suite of services, from designing the air fryer to ensuring it met international safety standards. The turnkey provider also managed the supply chain, allowing the startup to focus on sourcing local ingredients and developing their signature dishes. The result was a successful launch that celebrated local flavors while expanding the brand’s reach globally.

Sustainability at the CoreAn eco-conscious brand sought to integrate sustainable practices into their air fryer design. They partnered with a turnkey OEM that shared their commitment to the environment. The turnkey provider helped design an air fryer made from recycled materials, which was not only a hit with environmentally conscious consumers but also a testament to the brand’s dedication to sustainability. The turnkey solution ensured that the product was not only eco-friendly but also met all necessary certifications and passed rigorous quality checks.

Cross-Platform IntegrationA tech-forward brand wanted to integrate their air fryer with smart home technology. They chose a turnkey OEM that had expertise in IoT (Internet of Things) integration. The turnkey provider designed an air fryer that could be controlled via a smartphone app, offering users the convenience of cooking from anywhere. This innovative approach not only added value to the product but also helped the brand stand out in a crowded market, reinforcing their position as a leader in smart kitchen appliances.

Customization to PerfectionA boutique brand specializing in gourmet air fryers recognized the importance of customization to cater to niche markets. They collaborated with a turnkey OEM that offered personalized design and manufacturing services. The turnkey provider worked closely with the brand to create limited-edition air fryers that were not only visually stunning but also functionally superior. This unique offering allowed the brand to attract a loyal following of customers who appreciated the attention to detail and the exclusivity of their products.

Global Expansion Made EasyAn established brand looking to expand into new markets faced the challenge of understanding and adhering to different safety standards around the world. They partnered with a turnkey OEM that had a global footprint and a deep understanding of international regulations. The turnkey provider handled all aspects of certification and compliance, allowing the brand to enter new markets with confidence. This strategic move not only expanded the brand’s reach but also enhanced its reputation for reliability and quality.

Market Testing with Turnkey SupportA new entrant in the air fryer market wanted to test the waters before making a full-scale investment. They opted for a turnkey solution that included prototyping and pilot production. The turnkey provider helped them create a sample batch that was used for market testing and consumer feedback. This approach minimized risk and allowed the brand to make informed decisions based on real-world data. The success of the market test led to a full production run, thanks to the turnkey OEM’s support and guidance.

From Concept to RealityA visionary entrepreneur had a dream of creating an air fryer that would revolutionize the way people cook. With no experience in manufacturing, they turned to a turnkey OEM that could take their concept from the drawing board to a market-ready product. The turnkey provider not only manufactured the air fryer but also helped refine the product design, secured patents, and managed the distribution process. This collaboration turned a dream into a reality, propelling the entrepreneur’s brand into the spotlight.

These success stories highlight the power of turnkey solutions in the air fryer market. By partnering with a turnkey OEM, brands can leverage expertise, streamline processes, and focus on what they do best—innovating and growing their business.

In embracing the turnkey UL certified air fryer OEM approach, brands are not just adopting a manufacturing strategy; they’re investing in a future where innovation meets reliability. This collaboration offers a seamless path to market, ensuring that every product not only meets but exceeds consumer expectations. Let’s delve into the transformative benefits that come with this partnership.

The integration of cutting-edge technology into air fryer designs is a testament to the evolution of kitchen appliances. Brands that choose to work with turnkey UL certified OEMs gain access to the latest innovations, from energy-efficient heating elements to smart features that enhance user experience. This fusion of technology and design keeps products competitive in a rapidly changing market.

Streamlined production processes are a cornerstone of the turnkey approach. By outsourcing manufacturing to a certified OEM, brands can reduce the complexities of production management. This allows them to focus on their core competencies, such as brand development and marketing, while the OEM handles the intricacies of assembly, quality control, and compliance with safety standards.

Quality assurance is paramount in the appliance industry, and a turnkey UL certified air fryer OEM guarantees that every unit meets stringent safety and performance criteria. The certification process ensures that the product is not only safe for consumers but also reliable, reducing the risk of recalls and enhancing brand reputation. This trust is invaluable in a market where customer loyalty is hard-earned and easily lost.

Cost-effectiveness is a driving factor for many brands when considering an OEM partnership. Turnkey solutions often come with volume discounts and optimized supply chains, leading to significant cost savings. Moreover, the economies of scale achieved through mass production can lead to more competitive pricing, making the product more accessible to a wider audience.

The flexibility offered by turnkey OEMs is another significant advantage. Brands can quickly adapt to market trends and consumer demands by working with an OEM that can rapidly modify existing designs or develop new ones. This agility ensures that products remain fresh and relevant, even in the face of shifting consumer preferences.

Sustainability is a growing concern for both manufacturers and consumers. Turnkey air fryer OEMs often prioritize eco-friendly practices in their production processes, from sourcing materials to minimizing waste. By aligning with such partners, brands can promote their commitment to sustainability, which resonates with environmentally conscious consumers.

The logistics of international trade can be daunting, but turnkey OEMs often have a global footprint, making it easier for brands to enter new markets. From customs compliance to efficient shipping, these partners can navigate the complexities of international trade, ensuring that products reach customers promptly and without complications.

Innovation is the lifeblood of the appliance industry, and turnkey UL certified air fryer OEMs are at the forefront of this movement. They invest in research and development, constantly pushing the boundaries of what’s possible in air fryer technology. This commitment to innovation not only drives the industry forward but also provides brands with a competitive edge.

The collaboration between brands and turnkey air fryer OEMs fosters a culture of continuous improvement. By sharing insights and feedback, both parties can work together to refine products, improve manufacturing processes, and ultimately deliver the best possible experience to the end consumer.

In the ever-evolving landscape of kitchen appliances, the turnkey UL certified air fryer OEM approach is more than just a manufacturing strategy; it’s a strategic partnership that can lead to sustainable growth. It’s about leveraging the expertise of certified OEMs to create products that are not only safe, efficient, and innovative but also aligned with the values of today’s discerning consumers.

Brands that embrace this approach are not just catching up with market trends; they’re leading the charge into a future where quality, innovation, and sustainability go hand in hand. The success stories of those who have taken this leap of faith speak volumes about the potential for growth and the positive impact on both the brand and the consumer. As the market continues to evolve, the turnkey UL certified air fryer OEM approach will undoubtedly play a pivotal role in shaping the future of kitchen appliances.